memilanuk

Gold $$ Contributor

Just curious

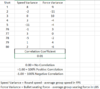

In all seriousness: a few years ago I got a new K&M arbor press, and splurged for the 'force indicator' setup with the bellville washer stack and mount for a dial indicator. At the time it didn't get a whole lot of use, because most of the ammo I was loading at the time had enough neck tension that it was *really* hard to see anything meaningful - i.e. when your loads have 40-50 'pounds' (supposedly the reading on the indicator are supposed to be a rough analog to 'pounds' of force, as I understand it) its difficult to tell when the seater is bottomed out on the die body, at least for me.

With lighter neck tension, in the 20-30 range, its easier to tell when the seater has reached the bottom and you're against the die body. Still seems like a process with a large degree of subjective 'feel' to it - i.e. hard to get repeatable numbers. I haven't intentionally gone with neck tension less than that as of yet.

I am curious if anyone, whether using heavy or light neck tension, has gotten repeatable results that reliably correlate to anything - reduced group size, lower ES/SD for muzzle velocity, tighter pressure traces with some device like an RSI Pressure Trace II, less vertical on target at distance, etc.

Monte

In all seriousness: a few years ago I got a new K&M arbor press, and splurged for the 'force indicator' setup with the bellville washer stack and mount for a dial indicator. At the time it didn't get a whole lot of use, because most of the ammo I was loading at the time had enough neck tension that it was *really* hard to see anything meaningful - i.e. when your loads have 40-50 'pounds' (supposedly the reading on the indicator are supposed to be a rough analog to 'pounds' of force, as I understand it) its difficult to tell when the seater is bottomed out on the die body, at least for me.

With lighter neck tension, in the 20-30 range, its easier to tell when the seater has reached the bottom and you're against the die body. Still seems like a process with a large degree of subjective 'feel' to it - i.e. hard to get repeatable numbers. I haven't intentionally gone with neck tension less than that as of yet.

I am curious if anyone, whether using heavy or light neck tension, has gotten repeatable results that reliably correlate to anything - reduced group size, lower ES/SD for muzzle velocity, tighter pressure traces with some device like an RSI Pressure Trace II, less vertical on target at distance, etc.

Monte