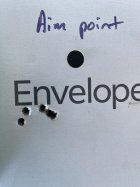

I don’t know exactly what to expect, here, but I’ve been curious about this subject for at least a decade. I’m wondering if anyone has tried this, or has any hunches, as I have just assembled it and not tried it yet.

This is a 40-X with a fast twist straight 6mm chambered in .243 Win. It is not the .243 40-X that is shooting well in the Manners F-Class stock, that gun is undisturbed.

Along the lines of pre-stressed concrete beams, I have carefully filled an opened barrel channel with the correct amount of semi-compressible fill, such that once compressed initially with C-clamps, and finally with strap clamps, the action is flat (or will be after heat cycles), and the barrel is being pressed very tightly into the stock, contacted and semi-surrounded by dampening material. This is tricky.

Plenty of times I’ve padded the channel for heavy barrels, but I have never pulled the barrel down from the top, and it is under significant pressure.

Like action screws, these hose clamp straps can be tightened and loosened as desired.

The rifle is as “dead” as any I have handled. The goal, as always, is to shoot small, but I don’t know if it is a step forward or backward. It’s certainly a step toward my old Crosman.22 pump pellet gun, but I can’t say they were wrong regarding the strap.

This is a 40-X with a fast twist straight 6mm chambered in .243 Win. It is not the .243 40-X that is shooting well in the Manners F-Class stock, that gun is undisturbed.

Along the lines of pre-stressed concrete beams, I have carefully filled an opened barrel channel with the correct amount of semi-compressible fill, such that once compressed initially with C-clamps, and finally with strap clamps, the action is flat (or will be after heat cycles), and the barrel is being pressed very tightly into the stock, contacted and semi-surrounded by dampening material. This is tricky.

Plenty of times I’ve padded the channel for heavy barrels, but I have never pulled the barrel down from the top, and it is under significant pressure.

Like action screws, these hose clamp straps can be tightened and loosened as desired.

The rifle is as “dead” as any I have handled. The goal, as always, is to shoot small, but I don’t know if it is a step forward or backward. It’s certainly a step toward my old Crosman.22 pump pellet gun, but I can’t say they were wrong regarding the strap.

Last edited: