XL105

Silver $$ Contributor

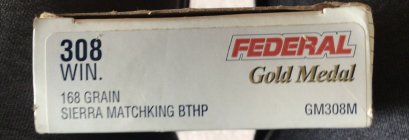

I bought a bunch of 308 brass on another site. He said they were once fired FGMM brass, fired out of bolt action rifles. Received them yesterday and I’m looking through some of them, I’m finding some with a ridge/rim around the necks of some of them.

they are head stamped FC 308 Win with sealed primers. Some of the primers look flat (not sure if it’s the sealant making them look flat) with some cratering.

If they are once fired brass I wouldn’t thing it’s necks starting to separate.

What’s happening?

they are head stamped FC 308 Win with sealed primers. Some of the primers look flat (not sure if it’s the sealant making them look flat) with some cratering.

If they are once fired brass I wouldn’t thing it’s necks starting to separate.

What’s happening?