I sized a piece with the expander ball back in the die and this is what I got. .291” at the base of the neck, .287” at the top. I also tried to screw the die further down but after a half turn it’s bottoming out on the base of my Forster press. This photo looks good to me.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Case neck okay?

- Thread starter leclairk

- Start date

I'd be getting on the phone with Whidden to let them help you work this out ... You're either not doing something correctly, the chamber is out of spec or the die is not correct.

The measurements given are all over the board.

There's three distinct rings on the neck in the first picture .. I'm guessing there's a lot of force getting the case into the die ... it certainly looks like multiple attempts to force it in and it gets further each time.

Are you lubing the case enough. What type of lube?

With enough force around the neck you can not only move the shoulder but completely collapse it.

The pics definitely do not look normal ....

The measurements given are all over the board.

There's three distinct rings on the neck in the first picture .. I'm guessing there's a lot of force getting the case into the die ... it certainly looks like multiple attempts to force it in and it gets further each time.

Are you lubing the case enough. What type of lube?

With enough force around the neck you can not only move the shoulder but completely collapse it.

The pics definitely do not look normal ....

DShortt

Gold $$ Contributor

You shouldn't be seeing a .004" taper on your case neck. What is your base to datum (shoulder setback) on fired brass with your die set like this?I sized a piece with the expander ball back in the die and this is what I got. .291” at the base of the neck, .287” at the top. I also tried to screw the die further down but after a half turn it’s bottoming out on the base of my Forster press. This photo looks good to me.

As others have said, either something isn't correct with your die or there's something about your setup that is causing problems.

I'd also try a different lube ... I've read so many threads about stuck cases and Hornady one Shot. I'd be willing to bet that alone might solve your issueGuess I’ll call Whidden. I’m using Hornady One Shot and everything feels smooth and consistent when I size the case. What a freaking pain in the ass. I’ve got a rifle class coming up in a couple months and I need to get a load developed.

There's also two different versions of one shot ... make sure your not using the cleaner/lube

Dusty Stevens

Shiner

You should be able to snatch a 6.5cm die at any sporting goods store such as academy or bass pro to get you thru your class. You just have a FL sizing die there, nothing special, so any die you grab off the shelf will do the same thing

you can also review this thread regarding one shot. Class John has a good video in there regarding making one shot work well... have to thoroughly clean the die first if other lubes also used.

hope it helps

Hornady One Shot

I have been using "One Shot" for a few years and have never had this happen. Instructions on using the lube were followed. Guess which three cases were "One Shot and which were Imperial Lube. I'll be taking the die apart today and check for gunk. Don't know what else to do. The Imperial Lube...

forum.accurateshooter.com

hope it helps

https://www.midwayusa.com/product/1010946147?pid=969530You should be able to snatch a 6.5cm die at any sporting goods store such as academy or bass pro to get you thru your class. You just have a FL sizing die there, nothing special, so any die you grab off the shelf will do the same thing

I would recommend this one, the case is supported when the expander ball does it’s job.

Would definitely try and screw that die down a bit further and measure the markings.. its doesn't look like its kissing the shoulders as round as they are, even with his brass annealed.The better question is how is my neck only sized halfway with the case fully inserted into the die.

How did you measure .002 bump? Unless there is a way to adjust the amount of neck sizing that your die will do, it's impossible to bump shoulder and only size part of the neck!! Is this a neck sizing die? Did you buy new from Whidden?How could my shoulder be bumped .002 if the case is not all the way in the die?

Last edited:

Okay, it’s something to do with the Forster CO-AX press. I took my RCBS die this time and screwed it all the way down until it hits the floating shell holder. I resized a few pieces of brass and my shoulder grew by .001”. I can’t screw the die down any further. It’s my understanding that if your shoulder grows it means your die needs to be screwed in more. Correct?

Or you cases are underlubed and the die body is pulling on the case on its way up extending it again. Try getting it further down the casing maybe quarter inch above the case head and upOkay, it’s something to do with the Forster CO-AX press. I took my RCBS die this time and screwed it all the way down until it hits the floating shell holder. I resized a few pieces of brass and my shoulder grew by .001”. I can’t screw the die down any further. It’s my understanding that if your shoulder grows it means your die needs to be screwed in more. Correct?

Note that if you are resizing the same case again and again to try and set the die, it will progressively increase in brass springback, so when you think you are close try it with a different brass.

Gargoyle

Finder Outer

That is truth right there. I am perplexed at the comment that he screwed the die so far down it won't go further. I can't wrap my head around this.Or you cases are underlubed and the die body is pulling on the case on its way up extending it again. Try getting it further down the casing maybe quarter inch above the case head and up

I lower my ram all the way. I screw the die down as far as I can until it makes contact with the shell holder jaws. I’m using a fresh piece of brass each time I make an adjustment. I’m not reusing the same piece to make adjustments. I will try more lube.That is truth right there. I am perplexed at the comment that he screwed the die so far down it won't go further. I can't wrap my head around this.

Google search from past forum posts says I need to shave off a small amount from the bottom of the die.

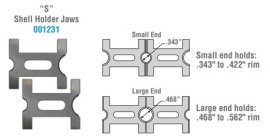

Just a double check.. you are using the Large end of the Forster shell holder jaws on the press correct?I lower my ram all the way. I screw the die down as far as I can until it makes contact with the shell holder jaws. I’m using a fresh piece of brass each time I make an adjustment. I’m not reusing the same piece to make adjustments. I will try more lube.

Google search from past forum posts says I need to shave off a small amount from the bottom of the die.

I amJust a double check.. you are using the Large end of the Forster shell holder jaws on the press correct?

View attachment 1397331

Gargoyle

Finder Outer

Ah, there it is...Once the die touches the shell holder, lift the ram and screw the die in 1/2 turn or until you see the whole neck sized.I lower my ram all the way. I screw the die down as far as I can until it makes contact with the shell holder jaws. I’m using a fresh piece of brass each time I make an adjustment. I’m not reusing the same piece to make adjustments. I will try more lube.

Google search from past forum posts says I need to shave off a small amount from the bottom of the die.

Similar threads

- Replies

- 22

- Views

- 1,517

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.