Infrequent Shooter

Gold $$ Contributor

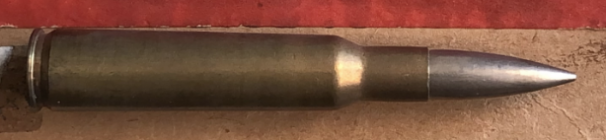

and the air flow velocity is increasedThink of it like this. Picture a straight wall case as a straw. If you blow air through that straw you have a steady flow of air and is relatively easy to push that column of air. Now add a restriction to the straw by placing a finger partially over the muzzle of the straw. It takes more pressure to move that same column of air. The shoulder on a case is a restriction and it's design will affect the pressure.