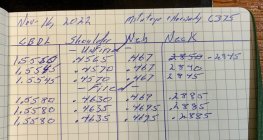

What is the maximum expansion at the web that wouldn’t concern you. I’m measuring some brass in a 25 CM I built & it’s more than I’m used to seeing. I understand whatever size the case is it has to expand to fit the chamber. On the attached pic you will see 2-1/2 thou. I am measuring not at the .200 line but immediately above the extractor groove? At the .200 line it’s 3 thou

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Case expansion at the web after fired 1x. What is acceptable max?

- Thread starter Lynn313

- Start date

The reason for asking is safety concerns. On a new rifle & new brass I always check pre-fire measurements against post fire. I don’t remember having this much.That's a worrisome amount, assuming you don't have a loosey goosey chamber. Actually, its worrisome period.

Hoot

Murray Brook

Silver $$ Contributor

I don't understand your concern. Could you elaborate. TKS

For any useful comment I'd need to know a great deal more about the techniques used to measure as well as the brass and the load. When I hear web I think of the solid head of the case. Long ago in my folly after reading Bob Hagel and Ken Waters judging pressure by expansion I bought a cute little jig from one of the majors for measuring case expansion to tenths resolving to half a tenth indicated for a guard digit.

In your circumstances I would section a case to see how the case head is laid out and what exactly is being measured. The point of greatest expansion is usually well forward of the solid web with a slight ring (not the bright ring of beginning case separation) as the brass thickens dramatically toward the solid head - except in ballon head cases not seen in the field lo these many years. For the solid head to expand very much is unusual and remarkable but for brass to move around with oval chambers or excessive headspace isn't. Readings can be affected by burrs from the extractor tilting the case in blocks and a number of other things to watch for.

In your shoes I'd likely try measurements of once fired, twice fired and three times fired neck sizing only and as little as possible to get an idea what a case fitted to the chamber is likely to measure. Continued expansion in the numbers mentioned would indeed be a concern and I'd verify load data and as fired.

In your circumstances I would section a case to see how the case head is laid out and what exactly is being measured. The point of greatest expansion is usually well forward of the solid web with a slight ring (not the bright ring of beginning case separation) as the brass thickens dramatically toward the solid head - except in ballon head cases not seen in the field lo these many years. For the solid head to expand very much is unusual and remarkable but for brass to move around with oval chambers or excessive headspace isn't. Readings can be affected by burrs from the extractor tilting the case in blocks and a number of other things to watch for.

In your shoes I'd likely try measurements of once fired, twice fired and three times fired neck sizing only and as little as possible to get an idea what a case fitted to the chamber is likely to measure. Continued expansion in the numbers mentioned would indeed be a concern and I'd verify load data and as fired.

Walt Krafft

Gold $$ Contributor

You need to measure the chamber before you have any meaningfull information.

I’ve always read & heard that expansion at the Webb could be the start of case head seperatio. The start of case head sep starts from the inside of case so no visible signs of a problem other than knowing the expansion took place by measuring.I don't understand your concern. Could you elaborate. TKS

YesAre you measuring first time fired cases?

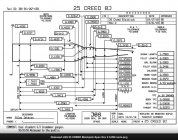

This was new brass measured before & after the 1st firing.. I usually do this on new brass in a new rifle for 2-3 firings until I think all looks good. I usually see under a .001 thou expansion. I used the thin part of expensive Mitutoyo calipers to measure right at the 1st full diameter above the extractor groove. I also just checked at the .200 line for to measure against the reamer print diagram.For any useful comment I'd need to know a great deal more about the techniques used to measure as well as the brass and the load. When I hear web I think of the solid head of the case. Long ago in my folly after reading Bob Hagel and Ken Waters judging pressure by expansion I bought a cute little jig from one of the majors for measuring case expansion to tenths resolving to half a tenth indicated for a guard digit.

In your circumstances I would section a case to see how the case head is laid out and what exactly is being measured. The point of greatest expansion is usually well forward of the solid web with a slight ring (not the bright ring of beginning case separation) as the brass thickens dramatically toward the solid head - except in ballon head cases not seen in the field lo these many years. For the solid head to expand very much is unusual and remarkable but for brass to move around with oval chambers or excessive headspace isn't. Readings can be affected by burrs from the extractor tilting the case in blocks and a number of other things to watch for.

In your shoes I'd likely try measurements of once fired, twice fired and three times fired neck sizing only and as little as possible to get an idea what a case fitted to the chamber is likely to measure. Continued expansion in the numbers mentioned would indeed be a concern and I'd verify load data and as fired.

My guess is the next firing will not show the same expansion. Is the webb designed for that kind of expansion on the initial case forming 1st fire?

Thanks for helping!

I didn’t look for it, but I can say nothing obvious. This is the 1st firing of new brass in a new rifle.Are you seeing a bright ring?

Using a caliper to measure case head expansion is pointless.

At the very least you need a blade micrometer that will measure to 0.00005 that is set

up to measure the case at the exact same spot every time.

Another thing to consider is the brass alloy itself, different manufactures brass will

have different results.

In my opinion firing factory ammo, measuring it and then using the same make brass

would possibly provide (maybe the same maybe not) a reasonable expansion measurement.

At the very least you need a blade micrometer that will measure to 0.00005 that is set

up to measure the case at the exact same spot every time.

Another thing to consider is the brass alloy itself, different manufactures brass will

have different results.

In my opinion firing factory ammo, measuring it and then using the same make brass

would possibly provide (maybe the same maybe not) a reasonable expansion measurement.

No. Expansion is the result of pressure inside the case with lack of support outside the case or hammering backwards.I’ve always read & heard that expansion at the Webb could be the start of case head seperatio. The start of case head sep starts from the inside of case so no visible signs of a problem other than knowing the expansion took place by measuring.

As implied above primer pockets can loosen and in magnum revolvers where there must be enough slack for cylinder rotation the primer pocket can actually be hammered shallower.

Case head separation is caused by the case stretching beyond elastic limits to fill the available space when base to shoulder space - headspace except in belted or rimmed where it is not called headspace but the mechanism is the same and rimmed straight cases can stretch and break as well as cases with shoulders- is excessive. The stretch marks will always show a bright ring outside where the case stretched and separates or will soon separate. Think of it as most of the case from the shoulder back is stuck to the chamber wall and at some point the head and some distance forward of the head moves back to fill the excess headspace. The internal thinning at the depth of the outside bright ring can be felt with a wire probe and seen with a bore scope. I used to keep some sectioned stretched cases around but I haven't seen them in years. Variation in base to shoulder length will show up on Wilson gages or my choice the Redding instant indicator or with attachments on calipers and so it goes.

ThanksNo. Expansion is the result of pressure inside the case with lack of support outside the case or hammering backwards.

As implied above primer pockets can loosen and in magnum revolvers where there must be enough slack for cylinder rotation the primer pocket can actually be hammered shallower.

Case head separation is caused by the case stretching beyond elastic limits to fill the available space when base to shoulder space - headspace except in belted or rimmed where it is not called headspace but the mechanism is the same and rimmed straight cases can stretch and break as well as cases with shoulders- is excessive. The stretch marks will always show a bright ring outside where the case stretched and separates or will soon separate. Think of it as most of the case from the shoulder back is stuck to the chamber wall and at some point the head and some distance forward of the head moves back to fill the excess headspace. The internal thinning at the depth of the outside bright ring can be felt with a wire probe and seen with a bore scope. I used to keep some sectioned stretched cases around but I haven't seen them in years. Variation in base to shoulder length will show up on Wilson gages or my choice the Redding instant indicator or with attachments on calipers and so it goes.

Dusty Stevens

Shiner

Sounds like you had a significant runout problem when it was chambered or some type of chambering issue. The reamer could be at fault but id point toward the chambering process. Either way, get it measured and fixed before somebody gets hurt.

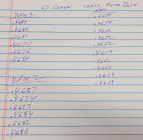

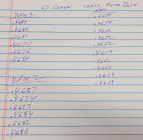

Bored so I did some unscientific quick and dirty setup and measurements of Hornady 6.5 Creed ammo

fired in two different rifles. Mike was .221 from base.

Measured 10 pcs of new ammo then 6 each fired in two different rifles.

The correct way would be to measure and mark individual cases fire them then remeasure recording

each individual case.

Average head expansion was .001

fired in two different rifles. Mike was .221 from base.

Measured 10 pcs of new ammo then 6 each fired in two different rifles.

The correct way would be to measure and mark individual cases fire them then remeasure recording

each individual case.

Average head expansion was .001

Last edited:

wboggs

Gold $$ Contributor

For years I have used 0.0015.

If you can get factory ammo, you can use the measurements for fired cases. Then reload the same brass and take measurements again. This has worked very well for me. At some point the expansion will equal factory and then get larger with increasing powder charges.

If you want to know the pressures with wilcats to a high degree of accuracy, you need pressing testing equipment.

The 0.015 has always proved to be a trouble free number for me.

If you can get factory ammo, you can use the measurements for fired cases. Then reload the same brass and take measurements again. This has worked very well for me. At some point the expansion will equal factory and then get larger with increasing powder charges.

If you want to know the pressures with wilcats to a high degree of accuracy, you need pressing testing equipment.

The 0.015 has always proved to be a trouble free number for me.

Similar threads

- Replies

- 9

- Views

- 2,210

- Replies

- 20

- Views

- 1,613

- Replies

- 13

- Views

- 1,014

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.