Tried to find a XX75 1816 arrow to make a carbon removal tool and none to be found around here. So question is has anyone made one out of mild steel that would just screw into a cleaning rod? I could whip one out on the lathe. Can't see why it wouldn't work or am I not seeing things right??

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Carbon scrapper to fit cleaning rod??

- Thread starter harv50

- Start date

Be careful using a XX75 shaft. It happens to be considerably harder than the barrel steel.harv50 said:Tried to find a XX75 1816 arrow to make a carbon removal tool and none to be found around here. So question is has anyone made one out of mild steel that would just screw into a cleaning rod? I could whip one out on the lathe. Can't see why it wouldn't work or am I not seeing things right??

Arrows are not oxides but they will scratch soft steel like a barrel. Arrows are drawn so during the process they get very hard. I cant believe you cant find 1816's however with the use of that infernal carbon that nearly dry fires every bow do to the speed race everyone is into these days, I can see why nobody stocks safe arrows anymore. The thought of accidentally eating carbon strands turns me off .

CatShooter

harv50 said:Tried to find a XX75 1816 arrow to make a carbon removal tool and none to be found around here. So question is has anyone made one out of mild steel that would just screw into a cleaning rod? I could whip one out on the lathe. Can't see why it wouldn't work or am I not seeing things right??

I put an over-sized brush with bore cleaner, on a BRASS (not aluminum) rod, hooked to a 1/4 drill, and give it 30 seconds.

Cleans fine and doesn't hurt anything - steel (of any kind) would give me pause.

hpshooter

Gold $$ Contributor

Would it be worth the effort to make a cutter from a case neck by cutting it off the case and filing notches in the end then soldering a brass screw into it to fit a section of cleaning rod then center it in the bore guide and clean the carbon ring out. Or, simply turn a brass blank and file the end like an end cutting end mill and use that.

Any un-coated or uncleaned piece of aluminum is going to have a layer of very hard aluminum oxide less than .001" on it that will easily scratch barrel steel. Once it is removed it immediately starts to form again.

T W Hudson

Any un-coated or uncleaned piece of aluminum is going to have a layer of very hard aluminum oxide less than .001" on it that will easily scratch barrel steel. Once it is removed it immediately starts to form again.

T W Hudson

CatShooter

hpshooter said:Any un-coated or uncleaned piece of aluminum is going to have a layer of very hard aluminum oxide less than .001" on it that will easily scratch barrel steel. Once it is removed it immediately starts to form again.

T W Hudson

^^^ THAT!!

I have been using a notched arrow for a few years now and have not damaged a chamber. Of course I will only use it when there is a build up of carbon at the neck throat transition. And then only enough to get through the carbon. The hardness of the arrow is what makes it work on the carbon. A borescope allows me to be sure of this.

However, I respect someone who can't see in their chamber and might not want to take the chance of damaging it.

There is also an option to glue an insert in the end of an arrow and use a modified target tip to act on the carbon. The picture shows an insert and two different target tips. It would be relatively easy to grind/cut the target tip to suit the chamber.

However, I respect someone who can't see in their chamber and might not want to take the chance of damaging it.

There is also an option to glue an insert in the end of an arrow and use a modified target tip to act on the carbon. The picture shows an insert and two different target tips. It would be relatively easy to grind/cut the target tip to suit the chamber.

Attachments

harv50 said:Tried to find a XX75 1816 arrow to make a carbon removal tool and none to be found around here. So question is has anyone made one out of mild steel that would just screw into a cleaning rod? I could whip one out on the lathe. Can't see why it wouldn't work or am I not seeing things right??

You're NOT seeing right. See and use J-B Non-Embedding Bore Cleaning Compound. 3 to 4 tight fitting patches with J-B will remove hard baked on carbon. Follow the instructions.

Just a few questions about the brush and bore cleaner method:

What is it about the carbon ring that defies regular bore and chamber brushing and demands special attention? Is it the thickness, the hardness, its location, all of the above or something else?

Does there have to be an abrasive in the cleaners to use for removing the carbon ring?

When the cleaner is applied to a patch or brush, does it just cover the carbon ring or does the brush & cleaner also act on clean steel on each side of the carbon?

How many times does the brush & cleaner method need to be repeated before the carbon is gone?

Why using a drill to turn the brush, how do you control the depth of the brush and avoid brushing the lands?

What is it about the carbon ring that defies regular bore and chamber brushing and demands special attention? Is it the thickness, the hardness, its location, all of the above or something else?

Does there have to be an abrasive in the cleaners to use for removing the carbon ring?

When the cleaner is applied to a patch or brush, does it just cover the carbon ring or does the brush & cleaner also act on clean steel on each side of the carbon?

How many times does the brush & cleaner method need to be repeated before the carbon is gone?

Why using a drill to turn the brush, how do you control the depth of the brush and avoid brushing the lands?

CatShooter

Tozguy said:Just a few questions about the brush and bore cleaner method:

What is it about the carbon ring that defies regular bore and chamber brushing and demands special attention? Is it the thickness, the hardness, its location, all of the above or something else?

Does there have to be an abrasive in the cleaners to use for removing the carbon ring?

When the cleaner is applied to a patch or brush, does it just cover the carbon ring or does the brush & cleaner also act on clean steel on each side of the carbon?

How many times does the brush & cleaner method need to be repeated before the carbon is gone?

Why using a drill to turn the brush, how do you control the depth of the brush and avoid brushing the lands?

Thickness is relative - but the reason for the procedure I use is the hardness and the location. The ash build up is very hard and resistant to solvents.

It is in a place (between the end of the case mouth, and the beginning of the lead), which defies removal by lengthwise brush strokes.

Only a rotary motion will get that hard ash out of that corner space.

I do not use abrasive pastes - just a bore brush and bore solvent. I use the solvent to wash away the ash crud and the brush loosens it... it does not "dissolve" the ash.

The brass/bronze of the brush will remove the ash that collects there if it is tight and spun (i.e., a 25 cal brush for a 224 bore).

Regardless of the beliefs and comments by those that didn't take metallurgy in school, brass/bronze cannot hurt barrel steel, the lands, the grooves, or the throat - not ever. It is way too soft.

I started shooting bench back in the 70s, and campaigned a 222 family rifle for a few years. I did Okie Dokie, and then the rifle lost it's edge, so I figured that the barrel was shot (badd pun), and retired it to whackin' crows and woodchucks.

This is way before we knew anything about the pressures of different loads. I later discovered that the load I was using (W-748) was producing about 26,000 to 30,000 psa - a very low pressure load. Which caused two things - the barrel did not burn out - when bore scoped 5 years ago, it looked unfired - but at 26,000 to 30,000 psi, the powder burned sooooo dirty, that the ash build up looked like the bottom of a barbecue pit.

That is when I started using over sized bore brushes and a brass rod in a drill. The first time I did it (for a few minutes with inspections every 30 seconds), and finely got all the ash out of there, the barrel looked new, and the rifle was reborn - it now shoots in the mid to high ones on a good day.

I have never seen or met a solvent that will remove ash (the way bore cleaners remove copper)... the ash MUST be removed by physical means - it is t-o-u-g-h-!

If the carbon/ash is removed mechanically by the brass/bronze brush, but that the brushing doesn’t hurt the barrel steel, does that make the carbon/ash deposit softer than the barrel steel?

Considering the narrow width and recessed location of the carbon/ash deposit, how much of the length of the brush would be in contact with the carbon/ash deposit at any one time?

Should I understand that you have no qualms about running a very tight fitting brass/bronze brush across the lands in the process of brushing out the carbon/ash ring?

Considering the narrow width and recessed location of the carbon/ash deposit, how much of the length of the brush would be in contact with the carbon/ash deposit at any one time?

Should I understand that you have no qualms about running a very tight fitting brass/bronze brush across the lands in the process of brushing out the carbon/ash ring?

CatShooter

Tozguy said:If the carbon/ash is removed mechanically by the brass/bronze brush, but that the brushing doesn’t hurt the barrel steel, does that make the carbon/ash deposit softer than the barrel steel?

Considering the narrow width and recessed location of the carbon/ash deposit, how much of the length of the brush would be in contact with the carbon/ash deposit at any one time?

Should I understand that you have no qualms about running a very tight fitting brass/bronze brush across the lands in the process of brushing out the carbon/ash ring?

Yes to the first.

"... how much of the length of the brush would be in contact with the carbon/ash deposit at any one time?" By definition, the amount of brush in contact with the ash, would be all of the area of ash, since the brush is larger.

... and Yes, you should understand that - it is what I said.

The brush is bigger then the throat. It is a caliber bigger. It will mostly be in the neck area. In front of the neck is the freebore where it is smooth. Then in front of that is the throat which is tapered. The brush is also softer then the barrel, and with JB or Iosso it doesn't usually take much to remove it. Now if you have carbon in the throat that is different and takes another method to get it out. Matt

Joe R

Gold $$ Contributor

Tried to find a XX75 1816 arrow to make a carbon removal tool and none to be found around here. So question is has anyone made one out of mild steel that would just screw into a cleaning rod? I could whip one out on the lathe. Can't see why it wouldn't work or am I not seeing things right??

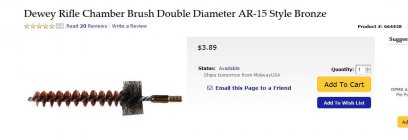

At the risk of sounding silly, isn't exactly for this reason that they make chamber brushes? (see below).

It works for me, and I have a borescope to verify it. If you do it regularly you won't get a carbon ring. Of course prevention is the key, just don't trim your brass so short in the first place.

Attachments

Similar threads

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.