Although I've been cleaning my rifles on a regular basis and verifying with my Teslong borescope camera, I was not cleaning them until completely free of all powder residue, tracking or carbon. Just clean enough (or so I thought) not spotless. Well......

I began to notice chambering issues with some loads that were seated close or into the lands. And although they shot well, it became bothersome. Then when pulling a live round for a called ceasefire, I had trouble pulling the bolt back. So I stopped shooting and returned to my shop.

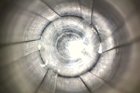

Upon running the Teslong camera up the chamber I found this:

A carbon buildup in the throat was jamming the bullets, and this is how a pressure spike can happen.

I removed it with a vigorous application of bronze brush and Slip 2000 carbon remover, but thought I'd post this pic because I'd never run across one like it before.

I began to notice chambering issues with some loads that were seated close or into the lands. And although they shot well, it became bothersome. Then when pulling a live round for a called ceasefire, I had trouble pulling the bolt back. So I stopped shooting and returned to my shop.

Upon running the Teslong camera up the chamber I found this:

A carbon buildup in the throat was jamming the bullets, and this is how a pressure spike can happen.

I removed it with a vigorous application of bronze brush and Slip 2000 carbon remover, but thought I'd post this pic because I'd never run across one like it before.