222Jim

Silver $$ Contributor

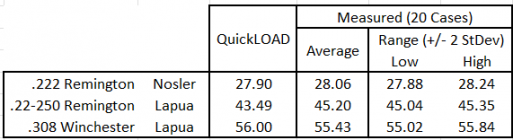

I’ve documented my methodology to calibrate (“true”) QuickLOAD that gives me predicted velocities that are typically within +/- 5 fps of my measured velocities.

The foundation of this method is, for a given handload (caliber, powder & charge, and bullet), to enter the obvious factors (i.e., actual bullet weight and diameter, cartridge and case length, barrel length, and maximum case capacity) and an improved estimate of the weighing factor. Then adjust the:

If this interests you, my methodology and results are described in more detail in the attached pdf document.

I’d welcome your thoughts, comments, and suggestions on what bullets and powders to apply this to next.

The foundation of this method is, for a given handload (caliber, powder & charge, and bullet), to enter the obvious factors (i.e., actual bullet weight and diameter, cartridge and case length, barrel length, and maximum case capacity) and an improved estimate of the weighing factor. Then adjust the:

- Powder Burn Factor until the predicted and measured velocities match for large jump handloads, then

- Shot Start (Initiation) Pressure until the predicted and measured velocities match at different jumps.

If this interests you, my methodology and results are described in more detail in the attached pdf document.

I’d welcome your thoughts, comments, and suggestions on what bullets and powders to apply this to next.