Guys, I got some seconds at a good price. So I added to the pile. They will work for SHTF if nothing else. I measured some samples. I have few boxes of the same in grade 1 so I measured those in comparison.

There was more variation in weight with some outliers but the majority of the seconds weighed what they were supposed to. That’s an easy enough thing to contend with.

Diameter was exactly the same. No issue there.

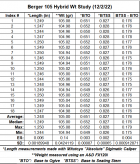

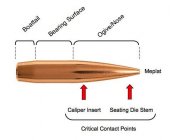

Base to ogive for the firsts were extremely consistent with a very small deviation. I can remember exactly but lets say 1.650 on the comparator. That’s just a for instance number.

Base to ogive on the seconds is the reason they made the seconds pile Im pretty sure. Probably 50% were exactly the same measurement as the firsts or controls so 50% 1.650. 30% were strangely exactly .005 higher so 1.655. That almost looked like what I see when I’m trying to dial a machine in. Very few were over 1.655. Maybe 5% 1.657 then 5% at 1.648. The remaining 10% were1.6525. So

Firsts 1.650

Seconds

5 @ 1.648

50 @ 1.650. Same as control or first run

10 @ 1.6525

30 @ 1.655

5 @. 1.657

So I got curious and measured samples from Lapua, Sierra, Hornady, and Nosler in a few different calibers. All first run.

Weights We’re pretty consistent.

Base to ogive for most would be within +/-.0015. One box varied +/-.0035. But in every box but 1

i found a piece or two that was off by .008 or more from the mean. Obviously an outlier in what are known to top tier premium match bullets. As a precision shooter you would want to identify and remove those I would think.

1. I doubt I’ll buy any more of the seconds but my experimental side would like to know if I shoot well enough to tell a difference If I did no sorting? For group size and velocity, and at distance. I probably will test this just a bit if for no other reason than “Because I Can”.

2. My next question would be if I did sort and only used the bullets that matched my 1st run specs by weight and bullet base to ogive would I see any change in accuracy?

3. If specs are otherwise identical, how much variation in weight does it take to see a noticeable difference at 1000 yards?

4. Even though variation exists from bullet base to ogive. When the bullet is seated in a case the cartridge base distance to the ogive for your loads would be identical. But the base depth in the cartridge will change and case capacity would vary slightly. How much does it take to make a noticeable differenceat 1000 yards?

5. If base to ogive depth varies, it should theoretically change the flight characteristics of the projectile slightly. How much of that variation would it take to make a difference at 1000 yards If velocity remained identical?

Obviously I have had way to much time on my hands. I am stuck inside with the flu. I don’t really expect answers to any of these questions but I’m sure some of you folks have experience with some of this. I’ve measured enough bullets over a long period to know even though they are from the same lot and close, they are not clones. There are some minute differences. I just wonder how much of that difference it takes to matter.

There was more variation in weight with some outliers but the majority of the seconds weighed what they were supposed to. That’s an easy enough thing to contend with.

Diameter was exactly the same. No issue there.

Base to ogive for the firsts were extremely consistent with a very small deviation. I can remember exactly but lets say 1.650 on the comparator. That’s just a for instance number.

Base to ogive on the seconds is the reason they made the seconds pile Im pretty sure. Probably 50% were exactly the same measurement as the firsts or controls so 50% 1.650. 30% were strangely exactly .005 higher so 1.655. That almost looked like what I see when I’m trying to dial a machine in. Very few were over 1.655. Maybe 5% 1.657 then 5% at 1.648. The remaining 10% were1.6525. So

Firsts 1.650

Seconds

5 @ 1.648

50 @ 1.650. Same as control or first run

10 @ 1.6525

30 @ 1.655

5 @. 1.657

So I got curious and measured samples from Lapua, Sierra, Hornady, and Nosler in a few different calibers. All first run.

Weights We’re pretty consistent.

Base to ogive for most would be within +/-.0015. One box varied +/-.0035. But in every box but 1

i found a piece or two that was off by .008 or more from the mean. Obviously an outlier in what are known to top tier premium match bullets. As a precision shooter you would want to identify and remove those I would think.

1. I doubt I’ll buy any more of the seconds but my experimental side would like to know if I shoot well enough to tell a difference If I did no sorting? For group size and velocity, and at distance. I probably will test this just a bit if for no other reason than “Because I Can”.

2. My next question would be if I did sort and only used the bullets that matched my 1st run specs by weight and bullet base to ogive would I see any change in accuracy?

3. If specs are otherwise identical, how much variation in weight does it take to see a noticeable difference at 1000 yards?

4. Even though variation exists from bullet base to ogive. When the bullet is seated in a case the cartridge base distance to the ogive for your loads would be identical. But the base depth in the cartridge will change and case capacity would vary slightly. How much does it take to make a noticeable differenceat 1000 yards?

5. If base to ogive depth varies, it should theoretically change the flight characteristics of the projectile slightly. How much of that variation would it take to make a difference at 1000 yards If velocity remained identical?

Obviously I have had way to much time on my hands. I am stuck inside with the flu. I don’t really expect answers to any of these questions but I’m sure some of you folks have experience with some of this. I’ve measured enough bullets over a long period to know even though they are from the same lot and close, they are not clones. There are some minute differences. I just wonder how much of that difference it takes to matter.