You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bullet Base to Ogive Grouping

- Thread starter wkdickinson

- Start date

wkdickinson

Gold $$ Contributor

First let me thank everyone who has commented in this thread, it certainly has generated much more of a discussion than I expected. With that said, I think we have gotten to the point where it is mostly "academic", as pointed out by Beiruty above.

But to delve even further - I have been having a sidebar discussion with Boyd Allen about the potential for variation in Head to Ogive (HTO) measurements of loaded rounds because of the different points on the bullet where the comparitor and the seating stem engage it. His premise was that there can be significant variation in the ogive "form" between individual bullets up where the seater contacts them because the jacket is likely unsupported by the core at that point.

Yesterday I loaded 96 rds of 6 Dasher ammo using the Berger 105 Hybrids I measured to start this thread. To explore Mr. Allen's premise I said I would measure some to see how what I found. Subsequently, he suggested I publish the results, so here is my response to him this morning:

Mr. Allen,

This morning I measured 30 of 96 Dasher rounds I loaded yesterday. My target "Head to Ogive" (HTO) measurement was 1.818". Following is a Minitab analysis of my measured data:

As you can see the distribution is fairly normal, but skewed to the lower side of the target measurement with the Median being 1.8170".

Below is a picture of a bullet showing the relative position of where the comparitor and seating stem engage the bullet. They are .234" apart and the diameter of the bullet at each is .238" and .185" respectively:

So from this test, I would agree that the variability of the ogive between the point of engagement of the comparitor and the seating stem, is likely significant. The next question is how much difference does it make on the target. I will have to give some thought as to how to test that.

Thanks for your interest and guidance in this. If nothing else it has been an interesting study and more knowledge is always better than less!

Wayne

But to delve even further - I have been having a sidebar discussion with Boyd Allen about the potential for variation in Head to Ogive (HTO) measurements of loaded rounds because of the different points on the bullet where the comparitor and the seating stem engage it. His premise was that there can be significant variation in the ogive "form" between individual bullets up where the seater contacts them because the jacket is likely unsupported by the core at that point.

Yesterday I loaded 96 rds of 6 Dasher ammo using the Berger 105 Hybrids I measured to start this thread. To explore Mr. Allen's premise I said I would measure some to see how what I found. Subsequently, he suggested I publish the results, so here is my response to him this morning:

Mr. Allen,

This morning I measured 30 of 96 Dasher rounds I loaded yesterday. My target "Head to Ogive" (HTO) measurement was 1.818". Following is a Minitab analysis of my measured data:

As you can see the distribution is fairly normal, but skewed to the lower side of the target measurement with the Median being 1.8170".

Below is a picture of a bullet showing the relative position of where the comparitor and seating stem engage the bullet. They are .234" apart and the diameter of the bullet at each is .238" and .185" respectively:

So from this test, I would agree that the variability of the ogive between the point of engagement of the comparitor and the seating stem, is likely significant. The next question is how much difference does it make on the target. I will have to give some thought as to how to test that.

Thanks for your interest and guidance in this. If nothing else it has been an interesting study and more knowledge is always better than less!

Wayne

The points on the nose you're referring to, the points BartsBullets says doesn't vary,, are affected by OGIVE RADIUS. And yes it does vary, I measure it with every bullet I shoot.

This can affect your BTO measure, no matter how custom your gizzy takes a datum. It's just a very sensitive area for measure.

To clear that potential for comparison of bullets, for bearing to base, the ogive radius has to first be qualified.

And to find out what your variance is, bearing and/or base length, you have to actually measure those.

Then you're closer to calculating BC with the summation of what you have, but knowing what each parameter actually is. That's the only way to do it.

As far as ogive radius variance affect to CBTO, this depends on nose form and seater stem, and seating forces applied. You cannot predict this, but you can sneak into desired CBTO exactly.

You can't talk about what in itself causes what to BC. All the numbers must first be known for calculation.

So the little half-efforts in your endeavor truly amount to no more than p*ssing in the wind.

This can affect your BTO measure, no matter how custom your gizzy takes a datum. It's just a very sensitive area for measure.

To clear that potential for comparison of bullets, for bearing to base, the ogive radius has to first be qualified.

And to find out what your variance is, bearing and/or base length, you have to actually measure those.

Then you're closer to calculating BC with the summation of what you have, but knowing what each parameter actually is. That's the only way to do it.

As far as ogive radius variance affect to CBTO, this depends on nose form and seater stem, and seating forces applied. You cannot predict this, but you can sneak into desired CBTO exactly.

You can't talk about what in itself causes what to BC. All the numbers must first be known for calculation.

So the little half-efforts in your endeavor truly amount to no more than p*ssing in the wind.

dstoenner

Silver $$ Contributor

So I was thinking about this and did an experimnt. I just got in yesterday 500 Barnes match Burner 6mm 112's. I sorted my original 300 for OAL and came up with 3 bands.

Band 1 - 1.320 to 1.324

Band 2 - 1.325 to 1.330

band 3 - 1.331 to 1.335

I have only done 100 of the new 500 and 2 years later they are falling into the same 3 bands. I thought if I measured from base to ogive as the OP did but add another measurement base to further up the nose. I have a Hornady set up and have .22 and .17 Trying to simulate the seating stem my .17 seemed a little closer to where I have seen marks compared to the .22.

I picked 2 bulets from each band but not at random. In Band 1 pulled 2 that measured 1.320, I band 2 I picked 2 that measured 1.327 and in band 3 I picked 2 that measured 1.330. Trying to see how the varying distribution effects these measurements.

Since we use the seating stem to set the ogive then the difference between the measurements would show how much the ogive varied and hence would be a dirrect correlation to the variance of jump/jam.

So here are my results:

OAL BTO BTSeating Stem Difference

1.320 .690 1.016 .326

1.320 .691 1.016 .325

1.327 .690 1.014 .324

1.327 .688 1.010 .322

1.330 .695 1.016 .321

1.330 .692 1.014 .322

So it seems to me that if we used all bullets without regard the biggest difference in seating for the Ogive variation would be .005. Within a given band it seems to be much lower, .001. It is also interesting to see how the variation of the 2 points seem to cancel out each other giving a pretty homogeneous mix. But it is also clear that measuring to OAL keeps BC and jump variation in check.

Food for thought

David

Band 1 - 1.320 to 1.324

Band 2 - 1.325 to 1.330

band 3 - 1.331 to 1.335

I have only done 100 of the new 500 and 2 years later they are falling into the same 3 bands. I thought if I measured from base to ogive as the OP did but add another measurement base to further up the nose. I have a Hornady set up and have .22 and .17 Trying to simulate the seating stem my .17 seemed a little closer to where I have seen marks compared to the .22.

I picked 2 bulets from each band but not at random. In Band 1 pulled 2 that measured 1.320, I band 2 I picked 2 that measured 1.327 and in band 3 I picked 2 that measured 1.330. Trying to see how the varying distribution effects these measurements.

Since we use the seating stem to set the ogive then the difference between the measurements would show how much the ogive varied and hence would be a dirrect correlation to the variance of jump/jam.

So here are my results:

OAL BTO BTSeating Stem Difference

1.320 .690 1.016 .326

1.320 .691 1.016 .325

1.327 .690 1.014 .324

1.327 .688 1.010 .322

1.330 .695 1.016 .321

1.330 .692 1.014 .322

So it seems to me that if we used all bullets without regard the biggest difference in seating for the Ogive variation would be .005. Within a given band it seems to be much lower, .001. It is also interesting to see how the variation of the 2 points seem to cancel out each other giving a pretty homogeneous mix. But it is also clear that measuring to OAL keeps BC and jump variation in check.

Food for thought

David

A seating die stem contacts the ogive well out toward the meplat of the bullet. A caliper insert contacts the ogive slightly above the bearing surface close to where the bullet will first contact the lands. The bullet boattail and bearing surface are both well below these two points. Thus, sorting bullets by BTO dimensions is generally going to have little, if any, effect on seating depth as measured using calipers. In other words, the entire BTO dimension is outside the two critical contact points; i.e. the point near the meplat at which the seating die stem contacts and pushes the bullet down into the case neck during seating, and the point just above the top of the bearing surface where we actually measure CBTO (i.e. effectively, seating depth). Sorting bullets using the BTO dimension, which lies completely outside these two critical points is not going to affect seating depth.

What variance in bullet BTO can affect are the length of bullet bearing surface inside/contacting the case neck wall, and the effective/usable case volume. The first of these would relate to possible frictional differences between the bullet bearing surface and the case neck wall for bullets with different BTO dimensions, the second would relate to possible changes in pressure for a given load. The real question is whether the difference between either of these two variables would be large enough for bullets that vary in BTO dimension by only a few thousandths that it would make a significant difference on the target. Of course, that can only be decided by the individual after rigorous testing.

But consider what we are actually doing when we carry out a seating depth test. Effectively, a seating depth test is also moving the bullet boattail/bearing surface in/out of the neck, thereby potentially changing both the amount of bearing surface contacting the case neck wall, as well as the effective case volume. With regard to both friction between the bullet bearing surface/neck wall and the relative change in effective case volume, how much change in velocity/pressure does one typically observe during seating depth testing? The answer largely depends on the total test range over which the bullets are seated. Seating a jumped bullet .050" or further off the lands can noticeably increase pressure; changing the seating depth of a jumped bullet by only .010" or .020", not so much. If I cannot detect a significant change in velocity/pressure across a typical seating depth test with bullets seated from about .003" off the lands, to about .024" - .027" off the lands (essentially all of the bullets I shoot will tune in somewhere within this range), then as an F-TR shooter I am going to be relatively unconcerned about BTO variance of a few thousandths. For that reason, I also sort bullets by OAL only. Nonetheless, for shooting disciplines where the ultimate precision of a load is everything (i.e. BR), the effect of BTO length variance is a testable commodity. If you think it might make a difference, the easiest approach initially is to load a few bullets from the two BTO extremes (i.e. longest/shortest) and see if you can shoot the difference in terms of precision, or detect any difference in velocity/pressure. Then you will know whether sorting bullets by BTO will have a significant effect on precision in your hands.

Likewise, and because I don't load my cartridges to touch or jam, I just don't have much if any concern for CBTO. . . . except to find a starting point off the lands. From there, my interest in finding a seating depth that consistently produces small groups. And when seating bullets, I want as consistent seating depth as possible along with neck tension and seating resistance. While a lot of the time with quality bullets, there's not a lot variance between the BTO and the seating stem contact point, but there can be a substantial difference from one lot and another. Sorting by bullet length makes good sense, especially for shooting long distances. But, because seating depth is so important and just .003 can make a notable difference, it just seems to me that one is going to find it difficult to get more consistent seating depths than sorting bullets from base to seating stem contact point.

I suppose getting custom bullets made with much higher tolerances, this issue might be eliminated for the most part???

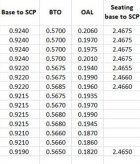

Here's some numbers from a small group of 169 SMK outliers that I made some measurements on and in my mind, it confirms my thinking about why I sort the way I do:

SCP=Seating Contact Point

That's true but for myself I sort commercial brands BTO looking for weird or odd ones that just don't belong. Yours or Toms I just load straight out of the box.Good news is they aren’t hurting anything.

Bart

? Lost me.Ogive in relation to head space should be unaffected

Head space has nothing to with any bullet.

When you set the head space on a rifle there is no bullet involved at all.

Ned Ludd

Silver $$ Contributor

I think the meaning is simply that at a given relationship of bullet ogive to the lands, the measurement between the bolt face and the measurement point on the bullet ogive will not change due to bullet BTO variance. Only the amount of bullet shank in the neck will change. That's really not much different than stating at a given [constant] seating depth, CBTO will also remain constant even with bullet BTO variance. Only how much bearing surface is seated down in the neck will change.? Lost me.

Head space has nothing to with any bullet.

When you set the head space on a rifle there is no bullet involved at all.

The word, I believe, is used incorrectly. Not in a grammatical sense. It's just wrong.I think the meaning is simply that at a given relationship of bullet ogive to the lands

When setting "HEADSPACE" a bullet is NOT involved at all.

I think that's what meant also. but once the word 'HEADSPACE' is used, it is not just misleading but completely wrong.I think the meaning is simply that at a given relationship of bullet ogive to the lands, the measurement between the bolt face and the measurement point on the bullet ogive will not change due to bullet BTO variance.

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.