DaveTooley

Gold $$ Contributor

Bingo!

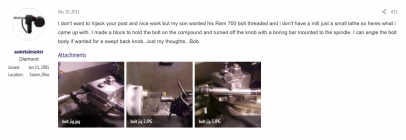

No the device you have shown is a LaBounty Bolt jig which I also own 2 of those, And they are for opening bolt faces and truing lugs, But they really aren't the best for doing that job. I also own a Phase II bolt threading jig like the one Dave Tooley just posted. They work very well, I am not home, But a while back I posted a pic of my old Shenwai 12x36 with my phase II bolt jig and a 300 Ultra mag bolt in it that barely clears the ways, I'll try to find it.Oh sorry, maybe I wasnt very clear

For "threading" the Bolt handle for a tactical knob

This is the only device I've seen so far.

I was going to take some 2" Alum round stock and drill a hole at the angle needed to secure the Bolt Body

then split it in half to clamp the bolt into. Then thread bolt handle

I just like seeing other ideas if there is a different way to do this.

Holding the bolt body in the 4 Jaw is fine as I've done it that way a few times, but somewhat risky if the bolt turns at all.

So far it hasn't happened to me yet, but those were my own bolts so I decided to just go for it.

View attachment 1643722

Good info on the bolt handle, thank youRemington stock bolt handles have a pretty small primary extraction ramp. I've found it much better in every way to just replace the handle with a PTG handle.

It's easy to make one though if you feel the need

That fixture allows you to dial it radially but axially.Oh sorry, maybe I wasnt very clear

For "threading" the Bolt handle for a tactical knob

This is the only device I've seen so far.

I was going to take some 2" Alum round stock and drill a hole at the angle needed to secure the Bolt Body

then split it in half to clamp the bolt into. Then thread bolt handle

I just like seeing other ideas if there is a different way to do this.

Holding the bolt body in the 4 Jaw is fine as I've done it that way a few times, but somewhat risky if the bolt turns at all.

So far it hasn't happened to me yet, but those were my own bolts so I decided to just go for it.

View attachment 1643722

I agree the LaBounty fixture leaves a lot to be desired. Good for radial work but not good axially. Other ways to skin that cat.No the device you have shown is a LaBounty Bolt jig which I also own 2 of those, And they are for opening bolt faces and truing lugs, But they really aren't the best for doing that job. I also own a Phase II bolt threading jig like the one Dave Tooley just posted. They work very well, I am not home, But a while back I posted a pic of my old Shenwai 12x36 with my phase II bolt jig and a 300 Ultra mag bolt in it that barely clears the ways, I'll try to find it.

Funny you brought that up, I was just eyeing those yesterday price shopping them.One eye opening way is use a rotating 3 jaw chuck in the tailstock holding the nose. BTW handy piece of equipment to have.

He said for the Howa it was easy as the bottom of the bolt handle is flat and has a hole/recess in it, so he just set it up in the mill leveled the flat bottom of the bolt handle and drilled and tapped it for a threaded insert then made an aluminum knob extension and bolted it on via the threaded insert.What I first thought and was hoping is

An easy way of holding a bolt to thread the bolt handle

See if you can see what he comes up with there that is easy and not expensive

Cool thank you,He said for the Howa it was easy as the bottom of the bolt handle is flat and has a hole/recess in it, so he just set it up in the mill leveled the flat bottom of the bolt handle and drilled and tapped it for a threaded insert then made an aluminum knob extension and bolted it on via the threaded insert.

Nice!!!!I'm not a machinist by any means, but couldn't you clamp the bolt body in the tool post, set the compound to the correct angle and put a cutter in the chuck? Kinda like a horizontal mill?

Annular cutter is what I was thinking. Then just a die in the chuck.Nice!!!!

Another interesting idea

Yes a guy could make that work, possibly by turning the O.D. with a Rotobroach

then just use a die to thread it

LA Bounty jig.Oh sorry, maybe I wasnt very clear

For "threading" the Bolt handle for a tactical knob

This is the only device I've seen so far.

I was going to take some 2" Alum round stock and drill a hole at the angle needed to secure the Bolt Body

then split it in half to clamp the bolt into. Then thread bolt handle

I just like seeing other ideas if there is a different way to do this.

Holding the bolt body in the 4 Jaw is fine as I've done it that way a few times, but somewhat risky if the bolt turns at all.

So far it hasn't happened to me yet, but those were my own bolts so I decided to just go for it.

View attachment 1643722

I will say the last one I did, I ground the bolt knob down on a 2x72 belt grinder roughly round enough to thread with a die and epoxied the knob on, lol. Its still on there and working fine after many years.Nice!!!!

Another interesting idea

Yes a guy could make that work, possibly by turning the O.D. with a Rotabroach

then just use a die to thread it

That would be the wrong jig my friendLA Bounty jig.

I have one of those, but thus far, other 'shiny objects' have kept me from trying it.

I was referring to the image in post #20.That would be the wrong jig my friend

That's for facing and doing bolt lugs

Wouldnt allow for threading bolt Knob

----------------------------------------------

The one Mr. Tooley Posted would be the one

since the whole body has to be held at an angle, as opposed to being inline and parallel to the spindle

Copy, now I understand what you're saying

Like most things. Yeah, it's been done before. I knew I had seen it at one point and went and found it. Instead of the boring bar you could do the annular cutter in the chuck.I'm not a machinist by any means, but couldn't you clamp the bolt body in the tool post, set the compound to the correct angle and put a cutter in the chuck? Kinda like a horizontal mill?