Last couple barrels used a .190 FB. I shoot 88g ELD, berger 90 VLD, and still have some Berger 90 HPBT and Sierra 90sWhat chamber reamer and fb for a .223 and 90 gr bullets?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Best cartridge to shoot the 90g .22 cal projectile?

- Thread starter NC/Br Shooter

- Start date

You still running this. Have you moved to something different? Reason ?I ran a 22 bra for almost 2 seasons. 95 gr smk, h4350, cci 250 @2930. .219 bore, not a single blown bullet out of roughly 3500 rds. I contribute that to one thing, .219 bore.

I've moved on to the6 bra, Sierra put the 95 gr smk on hold. That's the only bullet I wanted to shoot.You still running this. Have you moved to something different? Reason ?

Ned Ludd

Silver $$ Contributor

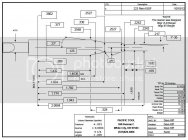

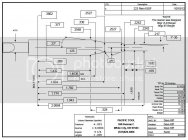

Here is a reamer print for PTG's 223 Rem ISSF reamer, which is one that many shooters loading 90s have used over the years.

This reamer cuts 0.169" freebore (center right of page), which I consider to be shorter than is optimal. I have used the basic specs from this print, solely changing the freebore length to suit my specific needs, as a template to order .223 Rem reamers on several occasions and have been very pleased with the results. I would suggest using a freebore of at least 0.190" to 0.220" for SMK 90s and Berger 90 VLDs. You can get away with using a freebore of 0.220" with the 88 ELDMs, but it is also a bit short for that bullet. A freebore on the order of 0.250" would be better for the 88s. If you want to run the 95 SMKs, all I'll say is that the freebore needs to be even a lot longer than that.

The bottom line is that there is nothing that says you can't stuff a long heavy bullet way down deep in the case. The main problem is not that you can't get the bullets to shoot with excellent precision, but that doing so will increase pressure significantly at a given velocity. F-TR shooters using these long heavy .224" bullets are often trying to get every last scrap of performance possible due to competing against .308 shooters using .308 Win rifles with 200+ gr high BC bullets, which can lead to extremely poor brass life. Having an optimal freebore for a given bullet means they can do so at slightly lower pressure, thereby extending brass life a bit. I've loaded all the .224" heavies in rifles with 0.169" freebore. They shot just fine, suggesting that these bullets don't mind having a lot of shank seated in the case neck. However, brass life wasn't so good and doing this may limit the realistic attainable velocity to a slower node. Of course, there is a lower limit or minimum freebore that you'd really want to have when loading the heavies, but I can't tell you exactly what that number would be. I have never tried to go any shorter than 0.169" at the low end. Only over time have I come to appreciate that slightly longer freebores seem to work better as the values listed in the paragraph above indicate.

A related issue that has something to do with evolution of reamer designs for these long heavy .224" bullets is seating depth. The 223 Rem ISSF was designed many years ago when the SMK and Berger 90 gr bullets were first being used in F-TR. At that time, the people involved were typically seating those bullets about .010" into the lands. I tried that years ago with my first F-TR rifle set up to shoot 90 VLDs (0.169" fb, 223 Rem ISSF reamer), but the precision with 90 VLDs was very mediocre. Further, I figured out very quickly that pressure and brass life would be made even worse by jamming the bullets. So I started moving them out incrementally. In my hands, you can often get the 90 VLDs to shoot very, very well when seated from about .004" to .007" into the lands. As mentioned, .010" into the lands seemed too far in my hands. But I also found that they start shoot extremely well again at ~.018" to .021" off the lands. Further, the optimal window for jumped bullets in this region was much wider and more forgiving than the relatively narrow window between .004" and .007" into the lands. Because of this and the pressure/brass life concerns, I have always jumped the .224" heavies; i.e. I have never found it necessary to seat them into the lands. But doing this meant that I was effectively giving up between .025" and .030" worth of the 0.169" freebore cut by the 223 Rem ISSF reamer as compared to those that were seating bullets .010" into the lands. So the seating depth actually used for tuned loads can also have an impact on what we might consider "optimal" freebore.

For the reasons listed above, I always suggest to try and find a seating depth optimum out of the lands/jumped first. One can always go back later and try seating the bullets incrementally into the lands if they are not able to find an acceptable seating depth when jumping the bullets. But this approach may need to be taken into consideration when having a reamer made, as the difference in seating depth between jumped and jammed might be as much as .040" or so in an extreme case, or about 1/4 the neck length of a .223 Rem case. Ideally, I would like to have at least half the case neck length occupied by bullet bearing surface with the heavies. They just seem to shoot better in my hands when there is plenty of shank seated in the case neck. But I also want them seated above the neck/shoulder junction whenever possible, to mitigate any pressure issues and/or issues caused by donuts. It is absolutely possible to accomplish these things, but one needs to have pretty good measurements and some idea of where a particular bullet might want to tune in to do it in an informed way.

This reamer cuts 0.169" freebore (center right of page), which I consider to be shorter than is optimal. I have used the basic specs from this print, solely changing the freebore length to suit my specific needs, as a template to order .223 Rem reamers on several occasions and have been very pleased with the results. I would suggest using a freebore of at least 0.190" to 0.220" for SMK 90s and Berger 90 VLDs. You can get away with using a freebore of 0.220" with the 88 ELDMs, but it is also a bit short for that bullet. A freebore on the order of 0.250" would be better for the 88s. If you want to run the 95 SMKs, all I'll say is that the freebore needs to be even a lot longer than that.

The bottom line is that there is nothing that says you can't stuff a long heavy bullet way down deep in the case. The main problem is not that you can't get the bullets to shoot with excellent precision, but that doing so will increase pressure significantly at a given velocity. F-TR shooters using these long heavy .224" bullets are often trying to get every last scrap of performance possible due to competing against .308 shooters using .308 Win rifles with 200+ gr high BC bullets, which can lead to extremely poor brass life. Having an optimal freebore for a given bullet means they can do so at slightly lower pressure, thereby extending brass life a bit. I've loaded all the .224" heavies in rifles with 0.169" freebore. They shot just fine, suggesting that these bullets don't mind having a lot of shank seated in the case neck. However, brass life wasn't so good and doing this may limit the realistic attainable velocity to a slower node. Of course, there is a lower limit or minimum freebore that you'd really want to have when loading the heavies, but I can't tell you exactly what that number would be. I have never tried to go any shorter than 0.169" at the low end. Only over time have I come to appreciate that slightly longer freebores seem to work better as the values listed in the paragraph above indicate.

A related issue that has something to do with evolution of reamer designs for these long heavy .224" bullets is seating depth. The 223 Rem ISSF was designed many years ago when the SMK and Berger 90 gr bullets were first being used in F-TR. At that time, the people involved were typically seating those bullets about .010" into the lands. I tried that years ago with my first F-TR rifle set up to shoot 90 VLDs (0.169" fb, 223 Rem ISSF reamer), but the precision with 90 VLDs was very mediocre. Further, I figured out very quickly that pressure and brass life would be made even worse by jamming the bullets. So I started moving them out incrementally. In my hands, you can often get the 90 VLDs to shoot very, very well when seated from about .004" to .007" into the lands. As mentioned, .010" into the lands seemed too far in my hands. But I also found that they start shoot extremely well again at ~.018" to .021" off the lands. Further, the optimal window for jumped bullets in this region was much wider and more forgiving than the relatively narrow window between .004" and .007" into the lands. Because of this and the pressure/brass life concerns, I have always jumped the .224" heavies; i.e. I have never found it necessary to seat them into the lands. But doing this meant that I was effectively giving up between .025" and .030" worth of the 0.169" freebore cut by the 223 Rem ISSF reamer as compared to those that were seating bullets .010" into the lands. So the seating depth actually used for tuned loads can also have an impact on what we might consider "optimal" freebore.

For the reasons listed above, I always suggest to try and find a seating depth optimum out of the lands/jumped first. One can always go back later and try seating the bullets incrementally into the lands if they are not able to find an acceptable seating depth when jumping the bullets. But this approach may need to be taken into consideration when having a reamer made, as the difference in seating depth between jumped and jammed might be as much as .040" or so in an extreme case, or about 1/4 the neck length of a .223 Rem case. Ideally, I would like to have at least half the case neck length occupied by bullet bearing surface with the heavies. They just seem to shoot better in my hands when there is plenty of shank seated in the case neck. But I also want them seated above the neck/shoulder junction whenever possible, to mitigate any pressure issues and/or issues caused by donuts. It is absolutely possible to accomplish these things, but one needs to have pretty good measurements and some idea of where a particular bullet might want to tune in to do it in an informed way.

Last edited:

linebaugh

Silver $$ Contributor

Think I have 500 of the 95s I could part with. Would need to check inventory.I've moved on to the6 bra, Sierra put the 95 gr smk on hold. That's the only bullet I wanted to shoot.

I keep forgetting to look up the load. Alpha brass for the 88 eldm’s and adg for the bergers. 6.5 staball for both and around 3150 I think.What brass you using and what velocity are you running?

I keep forgetting to look up the load. Alpha brass for the 88 eldm’s and adg for the bergers. 6.5 staball for both and around 3150 I think.What brass you using and what velocity are you running?

wboggs

Gold $$ Contributor

NedHere is a reamer print for PTG's 223 Rem ISSF reamer, which is one that many shooters loading 90s have used over the years.

View attachment 1411392

This reamer cuts 0.169" freebore (center right of page), which I consider to be shorter than is optimal. I have used the basic specs from this print, solely changing the freebore length to suit my specific needs, as a template to order .223 Rem reamers on several occasions and have been very pleased with the results. I would suggest using a freebore of at least 0.190" to 0.220" for SMK 90s and Berger 90 VLDs. You can get away with using a freebore of 0.220" with the 88 ELDMs, but it is also a bit short for that bullet. A freebore on the order of 0.250" would be better for the 88s. If you want to run the 95 SMKs, all I'll say is that the freebore needs to be even a lot longer than that.

The bottom line is that there is nothing that says you can't stuff a long heavy bullet way down deep in the case. The main problem is not that you can't get the bullets to shoot with excellent precision, but that doing so will increase pressure significantly at a given velocity. F-TR shooters using these long heavy .224" bullets are often trying to get every last scrap of performance possible due to competing against .308 shooters using .308 Win rifles with 200+ gr high BC bullets, which can lead to extremely poor brass life. Having an optimal freebore for a given bullet means they can do so at slightly lower pressure, thereby extending brass life a bit. I've loaded all the .224" heavies in rifles with 0.169" freebore. They shot just fine, suggesting that these bullets don't mind having a lot of shank seated in the case neck. However, brass life wasn't so good and doing this may limit the realistic attainable velocity to a slower node. Of course, there is a lower limit or minimum freebore that you'd really want to have when loading the heavies, but I can't tell you exactly what that number would be. I have never tried to go any shorter than 0.169" at the low end. Only over time have I come to appreciate that slightly longer freebores seem to work better as the values listed in the paragraph above indicate.

A related issue that has something to do with evolution of reamer designs for these long heavy .224" bullets is seating depth. The 223 Rem ISSF was designed many years ago when the SMK and Berger 90 gr bullets were first being used in F-TR. At that time, the people involved were typically seating those bullets about .010" into the lands. I tried that years ago with my first F-TR rifle set up to shoot 90 VLDs (0.169" fb, 223 Rem ISSF reamer), but the precision with 90 VLDs was very mediocre. Further, I figured out very quickly that pressure and brass life would be made even worse by jamming the bullets. So I started moving them out incrementally. In my hands, you can often get the 90 VLDs to shoot very, very well when seated from about .004" to .007" into the lands. As mentioned, .010" into the lands seemed too far in my hands. But I also found that they start shoot extremely well again at ~.018" to .021" off the lands. Further, the optimal window for jumped bullets in this region was much wider and more forgiving than the relatively narrow window between .004" and .007" into the lands. Because of this and the pressure/brass life concerns, I have always jumped the .224" heavies; i.e. I have never found it necessary to seat them into the lands. But doing this meant that I was effectively giving up between .025" and .030" worth of the 0.169" freebore cut by the 223 Rem ISSF reamer as compared to those that were seating bullets .010" into the lands. So the seating depth actually used for tuned loads can also have an impact on what we might consider "optimal" freebore.

For the reasons listed above, I always suggest to try and find a seating depth optimum out of the lands/jumped first. One can always go back later and try seating the bullets incrementally into the lands if they are not able to find an acceptable seating depth when jumping the bullets. But this approach may need to be taken into consideration when having a reamer made, as the difference in seating depth between jumped and jammed might be as much as .040" or so in an extreme case, or about 1/4 the neck length of a .223 Rem case. Ideally, I would like to have at least half the case neck length occupied by bullet bearing surface with the heavies. They just seem to shoot better in my hands when there is plenty of shank seated in the case neck. But I also want them seated above the neck/shoulder junction whenever possible, to mitigate any pressure issues and/or issues caused by donuts. It is absolutely possible to accomplish these things, but one needs to have pretty good measurements and some idea of where a particular bullet might want to tune in to do it in an informed way.

Thanks for your detailed reply. I appreciate the time you took to answer my question. As always, the devil is in the details. I assume there are smiths that specialize in this.

Thanks again

Bill

I’ve found the plain 22BR to have all the power needed and is a little simpler to source dies and get going with. You might find my log interesting:At one time the 90g was the heaviest. .22 cal bullet on the market, right?

I (read,) the 90g Smk is what a lot of ftr shooters use right?

Iv seen several wright up's on how to load 90g in the . 223.

Just curious on what the best cartridge is for the 90g .22 cal bullet.

I'm toying with the 22bra and 90s.

Having real good groups with 80g Smk.

Been using slower powders.

With the 90s, should I stay with the slower powders? I feel safer using those.

Anyway thanks for looking, welcome any thoughts

Thanks

My new 22BR!

Hi Folks. I've been posting up questions revolving around the 22BR recently. http://forum.accurateshooter.com/threads/new-22br-coming-which-dies.3979615/ http://forum.accurateshooter.com/threads/are-the-90s-worth-it-in-a-22br.3977792/ I also posted up the new stock I made for my 22-250, which...

forum.accurateshooter.com

Old Navy

Gold $$ Contributor

What twist?I shoot them in a 22 creedmoor. No modifications needed. No reason to run excessive pressure. Just hard to find them sometimes. I also shoot the 88eldm’s and they do pretty good.

Maximus1840

Gold $$ Contributor

I have a 22cm and run 90 grain smk’s over VV565 or H4831. 1:7 twist

Ramblerman

Silver $$ Contributor

Twist? Barrel?I ran a 22 bra for almost 2 seasons. 95 gr smk, h4350, cci 450 @2930. .219 bore, not a single blown bullet out of roughly 3500 rds. I contribute that to one thing, .219 bore.

Isn’t freebore dia of 0.2242” bit on tight side? Obviously this reamer is working fine for lot of you top shooters. Just wondering if cleaning becomes lot more critical at that dimension.Here is a reamer print for PTG's 223 Rem ISSF reamer, which is one that many shooters loading 90s have used over the years.

View attachment 1411392

This reamer cuts 0.169" freebore (center right of page), which I consider to be shorter than is optimal. I have used the basic specs from this print, solely changing the freebore length to suit my specific needs, as a template to order .223 Rem reamers on several occasions and have been very pleased with the results. I would suggest using a freebore of at least 0.190" to 0.220" for SMK 90s and Berger 90 VLDs. You can get away with using a freebore of 0.220" with the 88 ELDMs, but it is also a bit short for that bullet. A freebore on the order of 0.250" would be better for the 88s. If you want to run the 95 SMKs, all I'll say is that the freebore needs to be even a lot longer than that.

The bottom line is that there is nothing that says you can't stuff a long heavy bullet way down deep in the case. The main problem is not that you can't get the bullets to shoot with excellent precision, but that doing so will increase pressure significantly at a given velocity. F-TR shooters using these long heavy .224" bullets are often trying to get every last scrap of performance possible due to competing against .308 shooters using .308 Win rifles with 200+ gr high BC bullets, which can lead to extremely poor brass life. Having an optimal freebore for a given bullet means they can do so at slightly lower pressure, thereby extending brass life a bit. I've loaded all the .224" heavies in rifles with 0.169" freebore. They shot just fine, suggesting that these bullets don't mind having a lot of shank seated in the case neck. However, brass life wasn't so good and doing this may limit the realistic attainable velocity to a slower node. Of course, there is a lower limit or minimum freebore that you'd really want to have when loading the heavies, but I can't tell you exactly what that number would be. I have never tried to go any shorter than 0.169" at the low end. Only over time have I come to appreciate that slightly longer freebores seem to work better as the values listed in the paragraph above indicate.

A related issue that has something to do with evolution of reamer designs for these long heavy .224" bullets is seating depth. The 223 Rem ISSF was designed many years ago when the SMK and Berger 90 gr bullets were first being used in F-TR. At that time, the people involved were typically seating those bullets about .010" into the lands. I tried that years ago with my first F-TR rifle set up to shoot 90 VLDs (0.169" fb, 223 Rem ISSF reamer), but the precision with 90 VLDs was very mediocre. Further, I figured out very quickly that pressure and brass life would be made even worse by jamming the bullets. So I started moving them out incrementally. In my hands, you can often get the 90 VLDs to shoot very, very well when seated from about .004" to .007" into the lands. As mentioned, .010" into the lands seemed too far in my hands. But I also found that they start shoot extremely well again at ~.018" to .021" off the lands. Further, the optimal window for jumped bullets in this region was much wider and more forgiving than the relatively narrow window between .004" and .007" into the lands. Because of this and the pressure/brass life concerns, I have always jumped the .224" heavies; i.e. I have never found it necessary to seat them into the lands. But doing this meant that I was effectively giving up between .025" and .030" worth of the 0.169" freebore cut by the 223 Rem ISSF reamer as compared to those that were seating bullets .010" into the lands. So the seating depth actually used for tuned loads can also have an impact on what we might consider "optimal" freebore.

For the reasons listed above, I always suggest to try and find a seating depth optimum out of the lands/jumped first. One can always go back later and try seating the bullets incrementally into the lands if they are not able to find an acceptable seating depth when jumping the bullets. But this approach may need to be taken into consideration when having a reamer made, as the difference in seating depth between jumped and jammed might be as much as .040" or so in an extreme case, or about 1/4 the neck length of a .223 Rem case. Ideally, I would like to have at least half the case neck length occupied by bullet bearing surface with the heavies. They just seem to shoot better in my hands when there is plenty of shank seated in the case neck. But I also want them seated above the neck/shoulder junction whenever possible, to mitigate any pressure issues and/or issues caused by donuts. It is absolutely possible to accomplish these things, but one needs to have pretty good measurements and some idea of where a particular bullet might want to tune in to do it in an informed way.

Ned Ludd

Silver $$ Contributor

Yes, the +.0002" freebore spec is almost stupidly tight. It sometimes creates noticeable issues in terms of fairly simple things such as using a Hornady OAL gauge to identify "touching", or getting the jag/cleaning rod started moving down the bore without difficulty if the patch happens gets a little bunched up while it is inserted. I cannot say that I have ever noticed the relatively "tight" freebore causing any issues more critical than that, at least not with any certainty.Isn’t freebore dia of 0.2242” bit on tight side? Obviously this reamer is working fine for lot of you top shooters. Just wondering if cleaning becomes lot more critical at that dimension.

There seems to be a wide latitude in terms of of current thinking about freebore diameter. Years ago when I was planning my first .223 Rem F-TR rifle, and then again some time later when I saw the extreme precision with which it shot, I had conversations with Dave Kiff at PTG about the relatively tight freebore cut by his 223 Rem ISSF reamer (0.169" fb, .2242" fb diameter). My thought had been that the tight freebore would serve to automatically help center the fairly long Berger .224" 90 VLDs I was using and keep them concentric with respect to the bore. Dave agreed with this notion and suggested that had been part of the reason it had been designed that way in the first place. From that time onward, every .223 Rem reamer I have ordered has only differed in terms of optimizing freebore length; the requested diameter of .2242" has not changed.

In contrast, I just watched an interview of Erik Cortina with Speedy Gonzales the other day [post SW Nationals] where it was mentioned that Erik has been using a rifle chambered with a freebore that is a full .001" over bullet diameter. It obviously works very well for him. The real question here is what is the relative contribution of the freebore diameter to how well a rifle shoots? In other words, perhaps within reason having a slightly "tight" or slightly "loose" freebore has little effect on precision at all, with some other aspects of the reamer design being more critical. I don't know. Perhaps some bullets are more sensitive to freebore diameter than others. To be honest, I've always used the tight freebore diameter on .223 Rem chambers with the "if it's not broken, don't fix it" mentality, so I really don't know the answers here. All my .308 Win chambers have +.3085" freebore diameter (i.e. not tight), and they work just fine. I have never been motivated to change the relatively tight (+.0002") freebore on my .223 Rem chambers simply because they have always worked so well in my hands. I also know other F-TR shooters using chambers with .2245" freebore diameter, and they seem very pleased with the results. Maybe it just doesn't matter that much within a certain allowable range.

I recently ordered a new .223 Rem reamer from JGS specifically optimized for another heavy .224" bullet. My impression was that they did not really want to use the tight .2242" freebore diameter I requested, their standard freebore diameter being 0.2245". They provided explanations as to why that was that centered along the lines of their manufacturing/cutting tolerances; i.e. something like +/- .0003" for example. Basically, I was told that if they were to go with the 0.2242" spec, the +/- spec tolerance could litterally mean a freebore that was under bullet diameter. Nonetheless, they agreed to make it the way I requested and chambers cut with that particular reamer are shooting just as well as any other tight freebore .223 Rem chambers I've ever had cut over the years.

Optimizing freebore diameter is certainly an achievable goal. However, with the time and cost associated with having new barrels chambered these days, it's not something I intend to undertake any time soon as any barrel with a certain freebore diameter that might be discovered to be "sub-optimal" would effectively be useless to me. I'm sure there are those that have the resources to easily carry out these kind of tests and probably already have. Whether they choose to share their findings might be another story.

Last edited:

Thanks for detailed answer, I appreciate it. I was thinking about getting my own reamer to shoot 88 eldm. I was thinking about .2244” freebore dia and .230 freebore length.Yes, the +.0002" freebore spec is almost stupidly tight. It sometimes creates noticeable issues in terms of fairly simple things such as using a Hornady OAL gauge to identify "touching", or getting the jag/cleaning rod started moving down the bore without difficulty if the patch happens gets a little bunched up while it is inserted. I cannot say that I have ever noticed the relatively "tight" freebore causing any issues more critical than that, at least not with any certainty.

There seems to be a wide latitude in terms of of current thinking about freebore diameter. Years ago when I was planning my first .223 Rem F-TR rifle, and then again some time later when I saw the extreme precision with which it shot, I had conversations with Dave Kiff at PTG about the relatively tight freebore cut by his 223 Rem ISSF reamer (0.169" fb, .2242" fb diameter). My thought had been that the tight freebore would serve to automatically help center the fairly long Berger .224" 90 VLDs I was using and keep them concentric with respect to the bore. Dave agreed with this notion and suggested that had been part of the reason it had been designed that way in the first place. From that time onward, every .223 Rem reamer I have ordered has only differed in terms of optimizing freebore length; the requested diameter of .2242" has not changed.

In contrast, I just watched an interview of Erik Cortina with Speedy Gonzales the other day [post SW Nationals] where it was mentioned that Erik has been using a rifle chambered with a freebore that is a full .001" over bullet diameter. It obviously works very well for him. The real question here is what is the relative contribution of the freebore diameter to how well a rifle shoots? In other words, perhaps within reason having a slightly "tight" or slightly "loose" freebore has little effect on precision at all, with some other aspects of the reamer design being more critical. I don't know. Perhaps some bullets are more sensitive to freebore diameter than others. To be honest, I've always used the tight freebore diameter on .223 Rem chambers with the "if it's not broken, don't fix it" mentality, so I really don't know the answers here. All my .308 Win chambers have +.3085" freebore diameter (i.e. not tight), and they work just fine. I have never been motivated to change the relatively tight (+.0002") freebore on my .223 Rem chambers simply because they have always worked so well in my hands. I also know other F-TR shooters using chambers with .2245" freebore diameter, and they seem very pleased with the results. Maybe it just doesn't matter that much within a certain allowable range.

I recently ordered a new .223 Rem reamer from JGS specifically optimized for another heavy .224" bullet. My impression was that they did not really want to use the tight .2242" freebore diameter I requested, their standard freebore diameter being 0.2245". They provided explanations as to why that was that centered along the lines of their manufacturing/cutting tolerances; i.e. something like +/- .0003" for example. Basically, I was told that if they were to go with the 0.2242" spec, the +/- spec tolerance could litterally mean a freebore that was under bullet diameter. Nonetheless, they agreed to make it the way I requested and chambers cut with that particular reamer are shooting just as well as any other tight freebore .223 Rem chambers I've ever had cut over the years.

Optimizing freebore diameter is certainly an achievable goal. However, with the time and cost associated with having new barrels chambered these days, it's not something I intend to undertake any time soon as any barrel with a certain freebore diameter that might be discovered to be "sub-optimal" would effectively be useless to me. I'm sure there are those that have the resources to easily carry out these kind of tests and probably already have. Whether they choose to share their findings might be another story.

7 twist. Hawk HillTwist? Barrel?

Ned Ludd

Silver $$ Contributor

I can't see why those dimensions wouldn't work. I have a couple barrels that were cut with 0.220" freebore (still the 0.2242" dia) and they're a bit on the short side for the 88s. Don't get me wrong, you can shoot the 88s and they work just fine, but with .220" fb they're seated a bit deeper in the case than is optimal. I'm guessing that somewhere in the neighborhood of .250" to .275" would be optimal for the 88s. However, you run the risk of going too long for loading the 90s at that fb length in the event you ever wish to load a bullet other than the 88s. Loading the 88s or 90s with 0.230" fb should work just fine.Thanks for detailed answer, I appreciate it. I was thinking about getting my own reamer to shoot 88 eldm. I was thinking about .2244” freebore dia and .230 freebore length.

22 Creedmoor.

Similar threads

- Replies

- 24

- Views

- 1,630

- Replies

- 45

- Views

- 8,556

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.