A number of you have mentioned LarryWillis..... I snagged one of these off ebay for 29.99 couple weeks ago!!! (sorry Larry)

I suspect these are just too far out of spec to salvage as I don't want to bend the handle on my press trying. I do plan on using that collet die going forward though. Its an extra step but I seem to have plenty of time.

Also, I'm pretty certain the shoulders are not the problem.... I put one of the shells on my lathe and cut it off 1/4" below the shoulder... It wouldn't chamber.

I will pick up that Hornady comparator though. Thanks for the link.

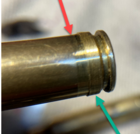

WinXb243, thanks for the detailed images. Am I reading that correctly? Belt Diameter .532 +.012 ? Does that mean max would be .544? All of my purchased brass fall below that... but won't chamber unless i turn them a down couple thousandths.

I suspect these are just too far out of spec to salvage as I don't want to bend the handle on my press trying. I do plan on using that collet die going forward though. Its an extra step but I seem to have plenty of time.

Also, I'm pretty certain the shoulders are not the problem.... I put one of the shells on my lathe and cut it off 1/4" below the shoulder... It wouldn't chamber.

I will pick up that Hornady comparator though. Thanks for the link.

WinXb243, thanks for the detailed images. Am I reading that correctly? Belt Diameter .532 +.012 ? Does that mean max would be .544? All of my purchased brass fall below that... but won't chamber unless i turn them a down couple thousandths.