I’ve searched the forum for a possible match to this issue I’m having… and nothing really answers my question.

Recently picked up some 257 wthby brass on gunbroker. The problem I’m having is that the brass won’t chamber in my Mark V.

I’ve tried about everything… originally bought some RCBS dies, no luck. Picked up a Forster Full Length resizing die… same issue.

Next, I tried the collet resizing die that everyone seemed to rave about… no luck there either.

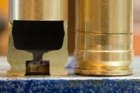

I did notice some pretty significant buildup of brass just ahead of the belt so, being a problem solver, I tried a few experiments. By the way, if I forced the Collet all the way down to the belt, It was nearly impossible to run through the die…. No matter how much lube was applied.

Being new to belted magnums, and pretty clueless to head-spacing, I made an assumption the shoulders weren’t getting pushed back enough. No matter what trick I tried, I couldn’t budge them.

Next, having a Metal Lathe, I trimmed back what appeared to be the buildup of brass just ahead of the belt. I really thought that was going to be the ticket. No Go. They did however drop nicely into the built in gauge of the collet die.

Finally, I measured the diameter of the belt on a new cartridge and compared to the diameter of the another one of the fired brass I picked up…. Voila.. they were all somewhere north of 3 to 4 thousands bigger. Now I’m curious. Back to the lathe to bring one of them back into spec. That was the problem…. And the turned case chambered nicely.

So after a long winded story, is all this brass junk, or, can I turn them down to spec without fear that I’ve compromised the integrity of the cases? Of course, I don’t want to trash my gun… but I’m not a big fan of throwing crap away either.

Just a bit more to the story… ALL of the cases were SHORT. Nearly 60 thousands short… I contacted the seller and he stated… he trimmed them all back to be consistent.. An old-Timer I know said not to worry about the length… they’d stretch back out after a few firings… just make sure to c.o.a.l. was within spec for the loaded ammo. That sounds reasonable…

Any thoughts? I’m not new to reloading… been doing it for nearly 40 years now. Always like to hear what people have to say… there’s always room to learn. Ya, I know... you get what you pay for.. don't buy junk... etc etc. but as my pappy used to say... Why buy new with used will do?

Recently picked up some 257 wthby brass on gunbroker. The problem I’m having is that the brass won’t chamber in my Mark V.

I’ve tried about everything… originally bought some RCBS dies, no luck. Picked up a Forster Full Length resizing die… same issue.

Next, I tried the collet resizing die that everyone seemed to rave about… no luck there either.

I did notice some pretty significant buildup of brass just ahead of the belt so, being a problem solver, I tried a few experiments. By the way, if I forced the Collet all the way down to the belt, It was nearly impossible to run through the die…. No matter how much lube was applied.

Being new to belted magnums, and pretty clueless to head-spacing, I made an assumption the shoulders weren’t getting pushed back enough. No matter what trick I tried, I couldn’t budge them.

Next, having a Metal Lathe, I trimmed back what appeared to be the buildup of brass just ahead of the belt. I really thought that was going to be the ticket. No Go. They did however drop nicely into the built in gauge of the collet die.

Finally, I measured the diameter of the belt on a new cartridge and compared to the diameter of the another one of the fired brass I picked up…. Voila.. they were all somewhere north of 3 to 4 thousands bigger. Now I’m curious. Back to the lathe to bring one of them back into spec. That was the problem…. And the turned case chambered nicely.

So after a long winded story, is all this brass junk, or, can I turn them down to spec without fear that I’ve compromised the integrity of the cases? Of course, I don’t want to trash my gun… but I’m not a big fan of throwing crap away either.

Just a bit more to the story… ALL of the cases were SHORT. Nearly 60 thousands short… I contacted the seller and he stated… he trimmed them all back to be consistent.. An old-Timer I know said not to worry about the length… they’d stretch back out after a few firings… just make sure to c.o.a.l. was within spec for the loaded ammo. That sounds reasonable…

Any thoughts? I’m not new to reloading… been doing it for nearly 40 years now. Always like to hear what people have to say… there’s always room to learn. Ya, I know... you get what you pay for.. don't buy junk... etc etc. but as my pappy used to say... Why buy new with used will do?

Last edited: