OK, so let’s go through the list.

First, you say powder volume variation is insignificant. Correction, what I was mentioning is case volume which is different than powder volume.

Second, we both agree that seating depth variation can make a large difference but you are saying OAL is meaningless because you think only distance from bullet leade contact datum to rifling lead is relevant. I would disagree with this since bullet seating depth for rounds seated to mag length (which is a long distance from rifling) also makes a big difference. I know this from first hand.

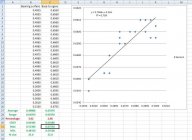

Third, I don’t really think one should be-little people since it is really not conducive to a constructive discussion. The fact is what I have show thus far is at least REAL data. Now I am not saying what you say is all incorrect but at least at face value, it is all talk and no data. If you want us to believe what you say is correct, show us some actual data to prove the point. After all, fair is fair, you say go do some test, present the results or anything else is chit-chat – it works both ways.