You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Barrel steel, beyond stainless

- Thread starter davidjoe

- Start date

3Sigma

Silver $$ Contributor

EDM was the only process I could think of offhand for that. Never cut that hard or tough of material, but it is used as cutting tools in our shop.Early M-60 barrels had a short life, then went to the Stellite

pressed in liner. M-240's are lined with Stellite-25. Some of

the varying compositions of Stellite can include Tungsten,

making for some tough machining. If you want to venture

even further,....Do some digging into EDM rifling.

Thanks for the education.

A chrome lined bore is good for 30-35K rounds ,whether it be SS or CM . In projectiles under 3200 FPS ,over that an flame cutting leads to throat erosion or leade degradation .

The Key may lie with a New super slick coating 2-4 microns in thickness deposited within the Bore ,so as to lessen the friction near half that of Teflon . We're working on it and I'll let you know . An inside small cylinder is extremely difficult to PVD or Pulsed Laser Deposition . Results of successful surface deposition have exhibited near Diamond like Hardness in addition to is extremely low coefficient of friction .

The Key may lie with a New super slick coating 2-4 microns in thickness deposited within the Bore ,so as to lessen the friction near half that of Teflon . We're working on it and I'll let you know . An inside small cylinder is extremely difficult to PVD or Pulsed Laser Deposition . Results of successful surface deposition have exhibited near Diamond like Hardness in addition to is extremely low coefficient of friction .

Tangent

Silver $$ Contributor

This is a very interesting thread. It always seemed to me that firearms were an old technology refined to their limit. Any advances seem to require improved materials science either for greater longevity or more performance. It will mean higher pressures, faster projectiles and more recoil. Makes me think that longevity is the thing to aim for as physics puts limits on how much more performance we can get, or how much we can take!

As new materials come on line, any change is possible. I get toThis is a very interesting thread. It always seemed to me that firearms were an old technology refined to their limit. Any advances seem to require improved materials science either for greater longevity or more performance. It will mean higher pressures, faster projectiles and more recoil. Makes me think that longevity is the thing to aim for as physics puts limits on how much more performance we can get, or how much we can take!

ask my Son some questions from time to time, when some of

my nightmares have kittens....LOL He's a Penn State papered

materials engineer. When Mechanical engineers have a problem

to solve regarding needs, the Material engineers go to work.

And he'll be the first to tell ya that finding a material is the easy

part. Figuring out how machine or form it is a different animal.

Kind of like when Titanium was first put to use. A good read on

that subject would be to look up Kelly Johnson and the Skunk

Works and how we ended up with the SR-71 and early variants.

Casull uses 17-4 in their single action revolver barrels.There’s plenty off room for improvement simply using well known existing Stainless Steels. 17-4 is a notable improvement without resorting to any exotic coatings or materials. LW50 has proven this out, and now Bartlein is offering "400MODBB" for a cut rifling option. Both are likely their select 17-4 offerings.

Mike

I was just on the phone with my boy at lunch time aboutCasull uses 17-4 in their single action revolver barrels.

Mike

a quick look up for barrel steels. He said to look at "Crucible

174 SXR". Maybe Frank can weigh in on the materials he has

tested, and any problems between gun drilling and the actual

cutting and lapping of the barrel.

We played with a couple of different grades from Crucible.....it was those grades that lead us to develop our own grade of material. We call it 400modBB. It's a modified 400 series stainless.I was just on the phone with my boy at lunch time about

a quick look up for barrel steels. He said to look at "Crucible

174 SXR". Maybe Frank can weigh in on the materials he has

tested, and any problems between gun drilling and the actual

cutting and lapping of the barrel.

We publicly released it late 2020. It's available for a $200 up charge. So far all the data we've gotten back has shown the barrels do last longer. For example an ammunition test barrel in 6.5CM only last for 1700 rounds give or take a little before it's junk. 1700 is about average. The test barrel we made out of our new 400modBB material went 3400+ before they seen a velocity loss and a pressure increase. So they still put another 100+ rounds on it to verify.

When we ordered our new material we have to take a mill run of it and have to take it all at one time. Also the material does cost us more over standard 416R material as well. So there was a cost increase to us just in the material costs alone.

Does the new material we have fit every application or needed by every shooter and to justify the costs? I'll say no. We have though seen other advantages with it as well. The new material also seems to foul less which in turns helps cleaning. This was a bonus that we couldn't have predicted.

Yes it does machine a little different but you use your normal speeds and feeds. I'll say your chamber reamers won't last as long but nothing that's a deal breaker either.

Later, Frank

Oh....I have to throw this in here....just because we are seeing more barrel life...

Doesn't mean shooters don't have to take care of the barrels! Or do less cleaning etc...you still have to do maintenance to them.

You want to abuse it....you can still wreck it!!!!!!!!!! And yes we have seen it done!

Doesn't mean shooters don't have to take care of the barrels! Or do less cleaning etc...you still have to do maintenance to them.

You want to abuse it....you can still wreck it!!!!!!!!!! And yes we have seen it done!

DaveTooley

Gold $$ Contributor

Considering the way I chamber and the cost of a HSS reamer my tooling cost is $3.75 per chamber. If I get 25% less tool life the cost per chamber goes up to $5.00.

Now with LW50 steel from Lothar Walther I've wrecked a reamer in 5 chambers using HSS.

Now with LW50 steel from Lothar Walther I've wrecked a reamer in 5 chambers using HSS.

jackieschmidt

Gold $$ Contributor

4140 is not a Stainless Steel. It is a Chrome Moly alloy steel.I’m in a materials class and my uncle is an engineer so maybe I can weigh in.

stainless steels like 4140, nickel chromium steels and high carbon steels are incredibly strong for their price, weight and can be machined easily they are also very weather resistant. My professor said that more chromium adds more weather resistance. Nickel, carbon and a few other elements add durability.

issues like in Vietnam when barrels were rusting out was because they weren’t chrome lined. Army probably went cheap with their steel and extra cheap with no lining. I’m not sure if modern barrels are lined or not.

A softer rust resistant metal like aluminum is a No go for a barrel. I believe that the metal will start to flex, budge and crack as a 60,000 psi round is probably pushing the elastic region on that metal quite a bit.

Edit: one thing I forgot to add was that tool steels like HSS and tungsten carbide will not make a cost efficient barrel. It will be probably $10,000+. My uncle said that titanium can become brittle, potentially enduce faster fire cracking in a bore. Titanium also likes to work harden unless special coolant and constant feed rates are being used. Then you’ll have to rifle it with what? A HSS button? That’s not gonna work, the barrel will eat that button for breakfast.

Sorry if this sound like a rant, I’ve been thinking about barrel steels a lot recently too.

I don’t think I will comment on the rest of your statements.

I didn’t mean to give any misleading information, I’m still learning and trying to weigh in.4140 is not a Stainless Steel. It is a Chrome Moly alloy steel.

I don’t think I will comment on the rest of your statements.

RegionRat

Gold $$ Contributor

Since you are still a student, don't feel bad about the idea that material naming is strange, especially for ones like steels. You will be finding out that each market segment has terminology that doesn't translate to the next one, and they break the rules as a rule.I didn’t mean to give any misleading information, I’m still learning and trying to weigh in.

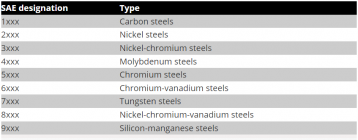

None of the naming rules are air tight, but generally when you see four digits it will be an alloy steel, and three digits will be "called stainless". Again, this is a loose generality. There are sometimes letters dropped into the middle for things like lead, boron, etc., and even some proprietary ones that don't follow the SAE or AISI conventions at all.

4140 is technically a Molybdenum alloy steel because it contains manganese (0.75 - 1.0%), molybdenum (0.15 - 0.25%), and chromium (0.8 - 1.1%). Most folks call it ChromeMoly Steel. There isn't enough chrome content to be called a stainless steel until it has more than 10.5%, so this one is an alloy steel.

Some of the chrome steels are called CRES or corrosion resistant when they have decent amounts of chrome, but it takes a fairly high chrome content to be what most folks would think of when they hear the words "stainless". A loose concept is that it takes on the order of >18% Cr to do what folks think of as stainless, but legal/treaty definitions kick in at 10% and technical definitions kick in at 10.5%.

You will learn in commercial terms, there are four groups of stainless steels: Ferritic, Austenitic, Martensitic, and Duplex. Here is an article that goes to show you how goofy the steel naming conventions can be.

https://www.asminternational.org/do...p039.pdf/2c98eb5e-746f-4e34-a6c3-161d600f801d

If at all possible, take any opportunity you are given to tour a live steel mill with an engineering class, especially the ones that make stainless and alloy steels.

As a update on what we are seeing in terms of life...

223 Remington Pressure and Velocity test barrels in standard material. The ammo makers are on average pulling them from service by about 3500 rounds.

I just got a email and phone call back from one ammo maker yesterday. We made them several 223 Rem. P&V test barrels out of the new material and I delivered them last October. They called me yesterday and asked if I wanted the first one back that they considered done/burnt up. I said yes please send it. The retired it at 6,915 rounds. At that round count they seen velocity loss and pressure changes. Shot some more rounds to confirm what they where seeing.

223 Remington Pressure and Velocity test barrels in standard material. The ammo makers are on average pulling them from service by about 3500 rounds.

I just got a email and phone call back from one ammo maker yesterday. We made them several 223 Rem. P&V test barrels out of the new material and I delivered them last October. They called me yesterday and asked if I wanted the first one back that they considered done/burnt up. I said yes please send it. The retired it at 6,915 rounds. At that round count they seen velocity loss and pressure changes. Shot some more rounds to confirm what they where seeing.

RegionRat

Gold $$ Contributor

That is good to hear @FrankG .

I'm not that far along and won't be able to make a comparison on mine because I made two changes at once, the new material and adopting a wildcat cartridge that is suspected to be a barrel burner. I will end up with no comparison basis, but this is beginning to sound like a good risk. I hope we can keep getting the new material so we can have a wider sample spread out amongst the shooting community.

I'm not that far along and won't be able to make a comparison on mine because I made two changes at once, the new material and adopting a wildcat cartridge that is suspected to be a barrel burner. I will end up with no comparison basis, but this is beginning to sound like a good risk. I hope we can keep getting the new material so we can have a wider sample spread out amongst the shooting community.

Last edited:

I think if you research the history of the M16 barrel issue you'll find a pissing contest between McNamara and military procurement of the day. With the soldiers paying the price.I’m in a materials class and my uncle is an engineer so maybe I can weigh in.

stainless steels like 4140, nickel chromium steels and high carbon steels are incredibly strong for their price, weight and can be machined easily they are also very weather resistant. My professor said that more chromium adds more weather resistance. Nickel, carbon and a few other elements add durability.

issues like in Vietnam when barrels were rusting out was because they weren’t chrome lined. Army probably went cheap with their steel and extra cheap with no lining. I’m not sure if modern barrels are lined or not.

A softer rust resistant metal like aluminum is a No go for a barrel. I believe that the metal will start to flex, budge and crack as a 60,000 psi round is probably pushing the elastic region on that metal quite a bit.

Edit: one thing I forgot to add was that tool steels like HSS and tungsten carbide will not make a cost efficient barrel. It will be probably $10,000+. My uncle said that titanium can become brittle, potentially enduce faster fire cracking in a bore. Titanium also likes to work harden unless special coolant and constant feed rates are being used. Then you’ll have to rifle it with what? A HSS button? That’s not gonna work, the barrel will eat that button for breakfast.

Sorry if this sound like a rant, I’ve been thinking about barrel steels a lot recently too.

I don't worry as much about the details of the steel, I concern myself with required use and pressure.

CQC rifles I keep operating pressures at 52,000 PSI maximum. M1 Carbines at 40,000 PSI, 5.56 and 6MM ARC at 52,000. Controlled rates of rapid fire, replacing spring kits and maintenance (using bore guides) provides long barrel life. My 30 carbines have great barrels and have been shot quite allot, 1 I'd bet 5,000 plus rounds.

If I was building a Dogtown rifle with an all day fire capability I'd pick a 50,000 to -60,000 PSI and add barrel length for velocity. Under controlled fire this would increase barrel wear and I'd hope to get 3,00 to 4,000 rounds.

For my chuck and crow rifles I run at 65,000 PSI and barrel length for velocity, after working loads in season 5 + rounds a day. These cartridge loadings burn steel, 2,000 + but not allow + rounds even with slow rates of fire. I run a 223 bolt rifle with a juiced load and my 6MM Remington is SAAMI at 65,000 PSI.

I don't know what steel was used in my 30 Carbines but everything else is chrome moly.

CQC rifles I keep operating pressures at 52,000 PSI maximum. M1 Carbines at 40,000 PSI, 5.56 and 6MM ARC at 52,000. Controlled rates of rapid fire, replacing spring kits and maintenance (using bore guides) provides long barrel life. My 30 carbines have great barrels and have been shot quite allot, 1 I'd bet 5,000 plus rounds.

If I was building a Dogtown rifle with an all day fire capability I'd pick a 50,000 to -60,000 PSI and add barrel length for velocity. Under controlled fire this would increase barrel wear and I'd hope to get 3,00 to 4,000 rounds.

For my chuck and crow rifles I run at 65,000 PSI and barrel length for velocity, after working loads in season 5 + rounds a day. These cartridge loadings burn steel, 2,000 + but not allow + rounds even with slow rates of fire. I run a 223 bolt rifle with a juiced load and my 6MM Remington is SAAMI at 65,000 PSI.

I don't know what steel was used in my 30 Carbines but everything else is chrome moly.

Perhaps what's needed is a combination of materials ,for the ultimate barrel . A SS barrel with an infused compressive bore of one of the below materials . Making the bore impervious to corrosion and wear . Just a thought . I'm still working on the BAM application ,as it's proving to be a superior applicable anti wearing material .

According to PhysOrg.com article from 2009, a material called wurtzite boron nitride has a greater indentation strength than diamond. The scientists who made this discovery have also calculated that another material, lonsdaleite, is even stronger than wurtzite boron nitride and 58 percent stronger than a diamond. This discovery marked the first case where a material exceeded a diamond in strength under the same loading conditions.

The extreme strength of the two materials is due to their reaction to compression. Most materials undergo a structural transformation under pressure that makes them stronger. Lonsdaleite and wurtzite boron nitride have subtle differences in the directional arrangements of their structural bonds, making them stronger than diamonds under pressure.

According to PhysOrg.com article from 2009, a material called wurtzite boron nitride has a greater indentation strength than diamond. The scientists who made this discovery have also calculated that another material, lonsdaleite, is even stronger than wurtzite boron nitride and 58 percent stronger than a diamond. This discovery marked the first case where a material exceeded a diamond in strength under the same loading conditions.

The extreme strength of the two materials is due to their reaction to compression. Most materials undergo a structural transformation under pressure that makes them stronger. Lonsdaleite and wurtzite boron nitride have subtle differences in the directional arrangements of their structural bonds, making them stronger than diamonds under pressure.

However the whole deal as my boy pointed out.....Coming up withPerhaps what's needed is a combination of materials ,for the ultimate barrel . A SS barrel with an infused compressive bore of one of the below materials . Making the bore impervious to corrosion and wear . Just a thought . I'm still working on the BAM application ,as it's proving to be a superior applicable anti wearing material .

According to PhysOrg.com article from 2009, a material called wurtzite boron nitride has a greater indentation strength than diamond. The scientists who made this discovery have also calculated that another material, lonsdaleite, is even stronger than wurtzite boron nitride and 58 percent stronger than a diamond. This discovery marked the first case where a material exceeded a diamond in strength under the same loading conditions.

The extreme strength of the two materials is due to their reaction to compression. Most materials undergo a structural transformation under pressure that makes them stronger. Lonsdaleite and wurtzite boron nitride have subtle differences in the directional arrangements of their structural bonds, making them stronger than diamonds under pressure.

a material is the easy part. Forming to the need, not so. Maybe one

day, barrels will be printed from exotics, or gun drilling and rifling

done in one operation with lasers. Really going outside the box.

RegionRat

Gold $$ Contributor

Needless to say, as I am sure you are well aware... that material parameters and Mother Nature are cruel...Perhaps what's needed is a combination of materials ,for the ultimate barrel . A SS barrel with an infused compressive bore of one of the below materials . Making the bore impervious to corrosion and wear . Just a thought . I'm still working on the BAM application ,as it's proving to be a superior applicable anti wearing material .

According to PhysOrg.com article from 2009, a material called wurtzite boron nitride has a greater indentation strength than diamond. The scientists who made this discovery have also calculated that another material, lonsdaleite, is even stronger than wurtzite boron nitride and 58 percent stronger than a diamond. This discovery marked the first case where a material exceeded a diamond in strength under the same loading conditions.

The extreme strength of the two materials is due to their reaction to compression. Most materials undergo a structural transformation under pressure that makes them stronger. Lonsdaleite and wurtzite boron nitride have subtle differences in the directional arrangements of their structural bonds, making them stronger than diamonds under pressure.

I was often asked by inexperienced leaders why I couldn't solve a problem with something they read about and got too excited.

They tended to get very excited by a parameter or discovery that hit some new extreme and insisted that it be applied to their cause. As an expert I had to let them down softly as they could make my life difficult if they took offense. Before we get too excited here, as someone who had to work on gun barrel materials and weapons systems problems, I will caution folks not to stare at one property too hard while ignoring all the others and wonder why it doesn't revolutionize the industry.

Once in a great while, we do in fact get a performance improvement from the discovery of a new extreme.

On the other hand, things like DLC, H-DLC, and a variety of diamond like coatings have not been the silver bullet that those managers demanded. Sure, many problems have been solved with hard coatings, but even those took lots of hard work and time to balance. Management expected results instantly, but my advice was to expect it to take years on average if the topic was to apply a new hard coating on an existing problem, and I might not end up using the one they read about in the end.

There is often a balance that requires the concepts of harness and ductility to be played against one another in a trade-off. For example, if we get things too hard and focus on compression loads, we often get brittle failures due to tension tension loads.

The keys to the problem are to take a look at all the loads and all the environmental issues that drive the problem. In our example of a gun barrel, we get to consider pressure, tribology and heat, as well as economics and producibility.

High Pressure in a gun barrel means the material sees high tension, not just surface compression and wear. Crack propagation and tensile failures in the substrate (base metal under the coating) are not the friend of very hard materials. Some diamond like surfaces are very abrasive instead of being low friction depending on the environment. Most are produced by methods that don't lend themselves to producing any shape or surface at will. ID coatings are not the same difficulty as OD coatings as a result.

Gas processes and things like nitriding have been used to improve the performance life of many complex shapes and parts, but I will tell you the processing changes often take many trade-offs and trials before we are happy. Ever wonder why we don't just salt-bath nitride every gun barrel? On paper, the process sounds like an instant success, but in practice it takes development and time to learn it isn't a silver bullet.

Sure, diamonds are hard, but have you ever seen how easy it is to cleave one? Mother nature plays her cruel trick on that crystal structure when you are not looking. To get past Mohr's Circle, you have to work pretty hard. If we push too hard or get distracted by compression harness alone, we get smacked by tensile and shear. Even then, when we get all three, there are still dimensions like tribology, corrosion, toxicity, fabrication, and economics to keep us humble.

I'm retired now, and wish the material researchers luck. The current administration's views on materials R&D are pathetic, so I will watch from the sidelines and cheer.

Similar threads

- Replies

- 66

- Views

- 10,800

- Replies

- 13

- Views

- 4,719

- Replies

- 47

- Views

- 5,856

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.