You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Another lathe question

- Thread starter 806guns

- Start date

urbanrifleman

Site $$ Sponsor

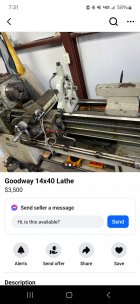

I was thinking more like $2000. Those are Taiwanese Okuma clones. Supposed to be great.

Taiwanese made, Okuma clone. From what I know they're decent machines.

Depending on motor size, simple enough to run off a VFD instead of using the phase converter.

Agree it's a bit high with just a 3 jaw for tooling.

Since it's your first machine and you (presumably) don't know how to evaluate old machines like this, you'd be best served to bring someone that can do it before purchase assuming you can test under power.

Depending on motor size, simple enough to run off a VFD instead of using the phase converter.

Agree it's a bit high with just a 3 jaw for tooling.

Since it's your first machine and you (presumably) don't know how to evaluate old machines like this, you'd be best served to bring someone that can do it before purchase assuming you can test under power.

I would steer clear from that lathe, Yes it's Taiwan, But it looks like it's towards the end of it's life. It doesn't come with a 4 jaw which will set you back about $500.00 for a Chinese one and $1200.00 for a Bison or equivalent.

If it was $500.00 and you could use it for a while maybe, But not what he is asking for that.

If it was $500.00 and you could use it for a while maybe, But not what he is asking for that.

butchlambert

Site $$ Sponsor

A close friend had one and it was a great lathe!Seems i may need to hold off for something better at this point thanks guys!

Since this will be your first machine, and unless you're in a hurry for some reason I'd keep looking and be patient.

If you don't currently own any machine tools, the cost of tooling-up will make your eyes bug-out if the lathe doesn't come with it. A 3-jaw chuck is about useless for rifle/barrel work (assuming this is what your intended use is?), so you need everything. Thousands of $$ even if buying used.

For barrel work you need to consider how you plan to do it- you need a short headstock if working through it, or a workaround plan such as the TBAS if the spindle is too long. Swing is irrelevant, but spindle length and bore, and distance between centers need to be considered depending on your work.

If you don't currently own any machine tools, the cost of tooling-up will make your eyes bug-out if the lathe doesn't come with it. A 3-jaw chuck is about useless for rifle/barrel work (assuming this is what your intended use is?), so you need everything. Thousands of $$ even if buying used.

For barrel work you need to consider how you plan to do it- you need a short headstock if working through it, or a workaround plan such as the TBAS if the spindle is too long. Swing is irrelevant, but spindle length and bore, and distance between centers need to be considered depending on your work.

THe digital adds a lot of value. It would cost 2000+ to add it to a lathe.

butchlambert

Site $$ Sponsor

At my age a D1-6 chuck is more than I want to deal with weight wise.Since this will be your first machine, and unless you're in a hurry for some reason I'd keep looking and be patient.

If you don't currently own any machine tools, the cost of tooling-up will make your eyes bug-out if the lathe doesn't come with it. A 3-jaw chuck is about useless for rifle/barrel work (assuming this is what your intended use is?), so you need everything. Thousands of $$ even if buying used.

For barrel work you need to consider how you plan to do it- you need a short headstock if working through it, or a workaround plan such as the TBAS if the spindle is too long. Swing is irrelevant, but spindle length and bore, and distance between centers need to be considered depending on your work.

Jonnyofalltrades

Silver $$ Contributor

Pretty hard to say from one picture.

Lathes like that go for crazy prices up here, so it looks like a decent deal to me.

Machines that have run with water based coolant can get ugly looking. It might not actually be that bad.

Check the condition of the cross slide ways, and the lengthwise ways right in front of the chuck. If those look decent, I would try it out. VFD's are cheaper, better, and easier than ever. Automation Direct is a great source.

Lathes like that go for crazy prices up here, so it looks like a decent deal to me.

Machines that have run with water based coolant can get ugly looking. It might not actually be that bad.

Check the condition of the cross slide ways, and the lengthwise ways right in front of the chuck. If those look decent, I would try it out. VFD's are cheaper, better, and easier than ever. Automation Direct is a great source.

shortgrass

Silver $$ Contributor

Like Western Oklahoma, the Texas Panhandle is pretty much a "machine desert". Local pricing will be higher than other locals. It's a trade off sometimes,,,, out right price or transportation. With just a 3 jaw chuck, a spider could be built for the chuck end, and certainly a spider would be needed on the outboard end, if the headstock is short enough. A lathe can build many things, not just chamber barrels. Check what has already been mentioned, length of the headstock, overall condition of the ways in particular. Be best to check under power. Does the coolant pump work? I see no tool post of tool holders in the pic, another expense.. Note that new tool posts usually come with an oversized T for the compound slot, and you'd need some way to make that fit properly.

Last edited:

shortgrass

Silver $$ Contributor

Notice is says, "fair condition". Could mean anything, the paint, or mechanicals. It also say, "make an offer". Ahhhh, says it comes with a BXA tool post. That's small for that sized machine.

Last edited:

Just keep waiting, Be ready with cash when the right deal pops up and don't hesitate to contact right away.

jds holler

Gold $$ Contributor

I know a little about a lot of stuff when it comes to shop equipment, including lathes.

One of the things I know, it that every day in this country, about 50 old geezers like us -- die. And all of their shop equipment and non-portable STUFF gets sold for pennies on the dollar, to someone who can make a plan to get it to where it needs to go.

If your plan can include hunting a fairly large area, and even include finding folks who are still above room temp, but needing to liquidate their estate, you'll be able to find a GREAT deal.

It is almost guaranteed that as soon as you pull the trigger on a deal, that sometime in the next few months you'll find a better one.

This and other forums ain't a bad way to start looking. jd

One of the things I know, it that every day in this country, about 50 old geezers like us -- die. And all of their shop equipment and non-portable STUFF gets sold for pennies on the dollar, to someone who can make a plan to get it to where it needs to go.

If your plan can include hunting a fairly large area, and even include finding folks who are still above room temp, but needing to liquidate their estate, you'll be able to find a GREAT deal.

It is almost guaranteed that as soon as you pull the trigger on a deal, that sometime in the next few months you'll find a better one.

This and other forums ain't a bad way to start looking. jd

paperpuncher

Gold $$ Contributor

Ain’t that the truth had a 15” colchester with a 10” buck 6 jaw it was a hump Heck even the 81/4” that I have now is a little strain to get on and offAt my age a D1-6 chuck is more than I want to deal with weight wise.

I'd suggest.

Go and have a look at any lathe that's within practical driving distance. If nothing else you'll start getting a feel for what your dollar buys. When you talk to people face to face you can learn a lot.

Some things are better or worse in the flesh.

If your intending to do barrel work on it the first thing to us need to know is the length from the back of the spindle to the front of the chuck is LESS THAN the length of the barrels you want to chamber. This can be done over the phone with a tape measure.

It's very hard to evaluate a dirty lathe but if you mount a dial indicator on the carriage and indicate off of the top of the flat way which the tailstock runs on. Run the carriage up and down the length of the bed and the indicator with show how much the carriage ways have worn "down" relative to the tailstock ways, which should have pretty minimal wear, especially up the business end.

Check that is has oil in the headstock, carriage and lead screw gearbox if applicable.

Run it through all the gears, check forward and reverse, engage power feed and thread cutting screws. Listen for problems which could indicate a failing bearing or broken gear caused by a crash.

Remove the chuck and check the mating taper and surface for damage. That taper is what centralises your chuck and if it's damaged or a loose fit you'll struggle. You can also turn the spindle and indicate off the taper. Push / pull the spindle and you'll see any play in the bearings.

Look inside the tailstock quill at the Morse taper and see if it's scraped or galled.

That should be a start. If you know someone with experience get them to show you what you what to look for and when you've found one you like ask if they will do a final inspection.

YEP tooling is going to cost a lot BUT it doesn't all need to happen at once, especially if your starting out. Within reason tooling can also be switched to another lathe. Chucks will be specific to the taper size of the machine but turning tools and indicators will be pretty much interchangeable in equivalent size machines. SO you can wait forever for a perfect lathe to come along OR buy something decent, learn, probably crash it, work out what you really need, sell it for what you paid and upgrade in time.

Go and have a look at any lathe that's within practical driving distance. If nothing else you'll start getting a feel for what your dollar buys. When you talk to people face to face you can learn a lot.

Some things are better or worse in the flesh.

If your intending to do barrel work on it the first thing to us need to know is the length from the back of the spindle to the front of the chuck is LESS THAN the length of the barrels you want to chamber. This can be done over the phone with a tape measure.

It's very hard to evaluate a dirty lathe but if you mount a dial indicator on the carriage and indicate off of the top of the flat way which the tailstock runs on. Run the carriage up and down the length of the bed and the indicator with show how much the carriage ways have worn "down" relative to the tailstock ways, which should have pretty minimal wear, especially up the business end.

Check that is has oil in the headstock, carriage and lead screw gearbox if applicable.

Run it through all the gears, check forward and reverse, engage power feed and thread cutting screws. Listen for problems which could indicate a failing bearing or broken gear caused by a crash.

Remove the chuck and check the mating taper and surface for damage. That taper is what centralises your chuck and if it's damaged or a loose fit you'll struggle. You can also turn the spindle and indicate off the taper. Push / pull the spindle and you'll see any play in the bearings.

Look inside the tailstock quill at the Morse taper and see if it's scraped or galled.

That should be a start. If you know someone with experience get them to show you what you what to look for and when you've found one you like ask if they will do a final inspection.

YEP tooling is going to cost a lot BUT it doesn't all need to happen at once, especially if your starting out. Within reason tooling can also be switched to another lathe. Chucks will be specific to the taper size of the machine but turning tools and indicators will be pretty much interchangeable in equivalent size machines. SO you can wait forever for a perfect lathe to come along OR buy something decent, learn, probably crash it, work out what you really need, sell it for what you paid and upgrade in time.

Been here, done it and received itAnother point, if in it's former life, it spent time in a school, run, don't walk.

hogpatrol

Gold $$ Contributor

Unfortunately you can't watch all of them all of the time. Had a student, actually an ME, on a lathe, 3/4" round aluminum bar stock sticking out about 20", 450 rpm, he was going to turn down the end for threads. NO CENTER. The noise was deafening. Needed to go to the wall and pull the switch. Had another student on a Bridgeport come to me and say "Mr. D, the mill's getting ready to fall over. He needed a chair to tighten the drawbar and had the chair under the table while he lowered it. Another hundred thousandths on the handle and it would have been on the floor. This Was a kid. School machines take a beating.Been here, done it and received itGosh kids can be REALLY hard on stuff!

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.