Just more info along this line:Its typically the Cu content that varies in cartridge brass. 68.5-71.5% by weight. Zn is 28.5%. The rest is Fe, Pb, and other trace elements.

Cartridge Brass Alloys Revealed by X-Ray Spectrometers « Daily Bulletin

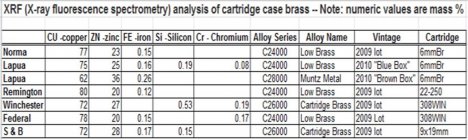

Are there significant metallurgical differences in the alloys used in various brands of cartridge brass? The answer is yes, and we have proof. Using a state-of-the-art X-Ray Fluorescence Spectrometer, some tech-savy Wisconsin shooters recently analyzed the alloys in seven different types of...