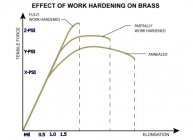

Suffice it to say that I'm not a metallurgist, but I had been fairly confident that annealing increases elasticity. I understand the term "elasticity" to mean the degree to which a metal is ductile. Then I read the article at the bottom of this post, which states "Freshly annealed brass will have less elasticity. Brass that has been fired many times will have more elasticity." (Page 3, Para 4)

Doesn't firing and sizing brass (without annealing) cause work hardening, in other words, the inverse of ductility? Doesn't annealing increase elasticity? If someone could educate me, I would appreciate it!

Doesn't firing and sizing brass (without annealing) cause work hardening, in other words, the inverse of ductility? Doesn't annealing increase elasticity? If someone could educate me, I would appreciate it!