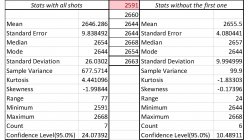

That's the thing. I always seem to get those 2591s tossed in there. I can live with 24 range ESs at this point, if it they are somewhat consistent.

Going to take Wayne's advice and retest the scale very very thoroughly and eliminate that.

Then Nedd's advice to change one thing at a time starting with my neck prep. First annealing, then maybe try using bushings and mandrels. Really thought Lee's collet was brilliant but maybe it's not. Might try a slightly larger expander mandrel after the collet.

Thanks to all for the help!

Just for kicks and giggles, you might try weighing the case associated with that odd velocity out. In my hands, it's not uncommon for an extreme velocity outlier to be associated with an extreme case weight/volume outlier. Cases at the upper end of the weight range (i.e. lower end of the volume range) tend to give higher than average velocities, whereas the lightest cases (i.e. higher end of the volume range) tend to give lower than average velocities. Sometimes a likely cause can be ascribed to the occasional extreme velocity outlier by simply weighing the cases. However, just be aware that although the relationship between case weight and case volume typically has a strongly linear correlation coefficient, is not

perfect, meaning outliers can always potentially cloud the issue. Nonetheless, weighing a few cases after the primers have been removed is fast and easy. If nothing else, the process may be informative and/or provide an incentive (or not) for sorting brass in an effort to minimize case volume variance.

With regard to neck prep, I used Redding Type S bushing dies as my sole sizing step for a number of years, and they work just fine. In an effort to improve the consistency of neck tension, more recently I have been using the Type S bushing dies with a bushing about .001" or so smaller than I would have as the sole sizing step, in order to tighten the necks down just a little below where I actually actually want them to end up. Then I use a mandrel that is typically .0015" under bullet diameter as the final sizing step. Making the neck slightly smaller with the bushing them opening it back up from the inside with the mandrel that is ~.0015" under bullet diameter will usually give between .0015" and .0020" neck tension (interference fit) due to a tiny bit of spring-back from the brass (i.e. the necks close back up about .0005" or so after the mandrel is withdrawn). For example, with Lapua brass, I might use a 0.336" bushing as the sole sizing step; OR I would use a 0.335" bushing followed by a 0.3065" mandrel. Both approaches would yield somewhere close to .002" neck tension (interference fit). The mandrels I use are from 21st Century Shooting and are available in a wide range of sizes in .0005" increments:

Expander Die Body Introducing the much anticipated Generation X Expander Die Body with viewing window! Set up of an expander die has not been easier! The viewing window allows the user to set the die to allow for optimal mandrel use without “bottoming out”. Machined out of 7075 Aluminum and...

21stcenturyinnovation.com

Our caliber specific expander mandrels are available in .0005” increments in calibers 22 to 338 and will range from .001” above bullet diameter to at least .003” below bullet diameter depending on caliber. This will allow the reloader to find proper neck tension to fine-tune their loads. The...

21stcenturyinnovation.com

There are certainly other sources for similar tools.

It is worth noting that using the mandrel after the bushing die requires basically double the effort to process brass this way. However, my feeling is that the consistency of neck tension is better than with a bushing die alone, at least for non-turned necks. However, that is getting down to a level where rigorously quantifying the difference between the two approaches is not so easy to do in a definitive manner. I think the two-step sizing approach is better, so I do it that way now, but am mentioning it here solely to give you something to think about. Whether you want (or need) to go to that length is something to think about.

Along the same line, you may decide there is some benefit to turning necks, especially something like a "skim pass" where you're really just removing the majority of the high spots on the outside of the neck wall. Sometimes doing that can have a beneficial effect ES/SD. Although I have the tools to do it, I choose not to turn necks. Again, just throwing another idea out there for you to mull over. The good news is that you can really try any or all of the suggestions you have received in this thread at any time. There is no need to have to try everything at once, just do it when you feel like it. If some approach seems to be of benefit, you can incorporate it into your reloading process at any time. The reason I mention this is that sometimes the constant testing/troubleshooting can take some of the fun out of shooting and reloading. The fun is what keeps us doing it, so don't let the process become too much of a chore and wreck your enjoyment of the sport.