Hey fellas,

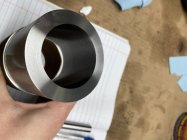

I need some help with my truing jig I am in the process of machining. My problem is, is that I have no idea of the locations for the 4 holes in the front of the jig and the 8 holes in the back for doing REM 700 long and short actions. Could somebody please help me or point me in the right direction? Any reliable dimensions would be greatly appreciated as I only have one piece of material, so I need to get it right the first time. Thanks again guys...

I need some help with my truing jig I am in the process of machining. My problem is, is that I have no idea of the locations for the 4 holes in the front of the jig and the 8 holes in the back for doing REM 700 long and short actions. Could somebody please help me or point me in the right direction? Any reliable dimensions would be greatly appreciated as I only have one piece of material, so I need to get it right the first time. Thanks again guys...