You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Acceptable variation in case weight?

- Thread starter mattri

- Start date

JMayo

Silver $$ Contributor

I just start weighing and make columns of like weight in rows light to heavy. In .10, .20, .30, .40 ......

I write weights on little pices of paper for headers as i descover them.

Then i split them in half.

Some of The outliers if there are any on each end become annealing test cases.

In the beginning i had so many weights separated it was ridiculous keeping up with them. By seasons end i had them mixed all up.

This was a start. Soon became a table full.

I write weights on little pices of paper for headers as i descover them.

Then i split them in half.

Some of The outliers if there are any on each end become annealing test cases.

In the beginning i had so many weights separated it was ridiculous keeping up with them. By seasons end i had them mixed all up.

This was a start. Soon became a table full.

Last edited:

Jager

Gold $$ Contributor

Sorting brass by weight has been an admired practice... for a very long time. We did that (do that) because it's pretty quick and pretty simple.

Before anyone decides to venture too far down that rabbit hole, however, I'd suggest perhaps taking a few of those weighed cases, syringe 'em with water, and find out how much water each one holds. (We don't do that - syringe 'em with water - too often, because it's slow and tedious and a royal pain in the ass.)

But do it a time or two, and see what the correlation is between case weight and case capacity.

Sometimes we end up surprised by things.

Before anyone decides to venture too far down that rabbit hole, however, I'd suggest perhaps taking a few of those weighed cases, syringe 'em with water, and find out how much water each one holds. (We don't do that - syringe 'em with water - too often, because it's slow and tedious and a royal pain in the ass.)

But do it a time or two, and see what the correlation is between case weight and case capacity.

Sometimes we end up surprised by things.

Last edited:

Unless you end up with a sort of smooth bell shaped distribution, you probably have not used an adequate sample size to represent the production process.

Many assume that variation in case weight is in the case head/groove.

Take your heavy outlier and remove weight in the groove to bring it to the weight mean you found (same head stamp).

I took off 1 grain from groove and rim (sorry for the rough cut).

Smoothed out, this much could probably go unnoticed between brands.

But not across the same lot of brass.

2 grains? Probably not.

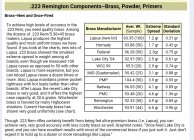

The process of forming brass should be an In Control process. It might take several hundred samples to fully describe weight distritribution. The same for projectiles, just with a tighter spread, and powder charges in factory ammo. Here's an example of factory ammo. My GUESS is that MOST of the variation is in case weight, not powder charge

Many assume that variation in case weight is in the case head/groove.

Take your heavy outlier and remove weight in the groove to bring it to the weight mean you found (same head stamp).

I took off 1 grain from groove and rim (sorry for the rough cut).

Smoothed out, this much could probably go unnoticed between brands.

But not across the same lot of brass.

2 grains? Probably not.

The process of forming brass should be an In Control process. It might take several hundred samples to fully describe weight distritribution. The same for projectiles, just with a tighter spread, and powder charges in factory ammo. Here's an example of factory ammo. My GUESS is that MOST of the variation is in case weight, not powder charge

Last edited:

as small as possible

but a plinker does not care

a hunter is only slightly better

most short range br shooters use such premium brass, they do not weigh

long range br some use 1 gr some use as small as possible.

run a length of masking tape on the edge of your table or desk/bench

weigh a handful.....now mark the tape in tenths over 2 or 3 grains that your sample shows.

build rows easy to see your spread and possible batches

but a plinker does not care

a hunter is only slightly better

most short range br shooters use such premium brass, they do not weigh

long range br some use 1 gr some use as small as possible.

run a length of masking tape on the edge of your table or desk/bench

weigh a handful.....now mark the tape in tenths over 2 or 3 grains that your sample shows.

build rows easy to see your spread and possible batches

sorry bs look at the rim,,too thinUnless you end up with a sort of smooth bell shaped distribution, you probably have not used an adequate sample size to represent the production process.

Many assume that variation in case weight is in the case head/groove.

Take your heavy outlier and remove weight in the groove to bring it to the weight mean you found.

I took off 1 grain from groove and rim (sorry for the rough cut).

Smoothed out, this much could probably go unnoticed between brands.

2 grains? Probably not.

i have heard the story by those that like to justify NOT DOING THE WORK.

fine for plinkers

That's the point I was trying to make (tongue in cheek). Most of the case weight variation in the same lot/headstamp is NOT in the rim/groove.

There's no way you could let a .223 case slip through with that much weight loss in the head.

Try to remove 2 grains from a 223 case head. See what that looks like.

Good factory loaded ammo with a large enough sample will show a distribution that is the independent combination of brass, projectile, powder and primer weights. See previous picture.

If you get a few grains total weight spread in hand loaded .223 ammo, YOUR process may not be In Control.

How tight you sort depends on your use.

Load development comparing powders, to find your node, ladder tests, even practice.

With the cost of going to a long range competition, a big game hunt, how is sorting too much trouble?

At the minimum, find the outliers.

I imagine that 6bra1k has much less than a grain total spread in his loaded ammo.

There's no way you could let a .223 case slip through with that much weight loss in the head.

Try to remove 2 grains from a 223 case head. See what that looks like.

Good factory loaded ammo with a large enough sample will show a distribution that is the independent combination of brass, projectile, powder and primer weights. See previous picture.

If you get a few grains total weight spread in hand loaded .223 ammo, YOUR process may not be In Control.

How tight you sort depends on your use.

Load development comparing powders, to find your node, ladder tests, even practice.

With the cost of going to a long range competition, a big game hunt, how is sorting too much trouble?

At the minimum, find the outliers.

I imagine that 6bra1k has much less than a grain total spread in his loaded ammo.

Last edited:

RegionRat

Gold $$ Contributor

Rather than answer your question with some specific example that doesn't apply to you....

I would encourage you to test this for yourself and keep in mind that 3 grains difference in case weight in 223 isn't the same as 3 grains in 300 Win mag....

Rather than give you an answer. Here is a way to answer your own question based on your own brass and situation. It will help you decide if sorting (of any kind) is valuable or a waste of your time.

The following works best if "the batch" you are thinking of sorting is at least one or two hundred pieces.

Take the first random 30 cases and get an average and SD for the lot in question. That is just helpful to roughly show the center of a sorting by weight and what to expect for the spread of the sorting since you would end up with roughly SD x 6 = ES.

Collect as many of the tails of the curve into a sub group as possible to populate a test. Say at least 5 of each of the extreme tails.

You can decide to keep the whole batch sorted or just keep these two extreme sub groups, but you will want to sort them on a table by weight bin till you make your decision. For this test, you will want to make it easy to find the heaviest and the lightest five samples.

The vast majority of the cases will fall into the middle 4 SDs, with far fewer falling into the -3SD and +3SD weight range.

If you can't find at least 5 for each of the two extreme bins, you pull a few from the ones next to them till you do get 5 of each tail. Record the weights of those two sub groups so you can start to understand both what to expect from brass batches and the answer to your original question.

Now you load up those two subsets and go test for group and velocity.

You will now be able to answer if the difference between those two was enough to bother with weight sorting, and you will also start getting an idea of how the QC is running on brass batches over time.

Smaller case volumes are more sensitive than larger ones. For example, if I pull 30 samples out of a batch of 223 and the ES is only around 3 grains, I don't do anything more. That value climbs with bigger cases. Notice that the examples in that chart above have some batches with an ES above 3 grains and some with ones well below. Buy good brass, shoot more and sort less. YMMV

I would encourage you to test this for yourself and keep in mind that 3 grains difference in case weight in 223 isn't the same as 3 grains in 300 Win mag....

Rather than give you an answer. Here is a way to answer your own question based on your own brass and situation. It will help you decide if sorting (of any kind) is valuable or a waste of your time.

The following works best if "the batch" you are thinking of sorting is at least one or two hundred pieces.

Take the first random 30 cases and get an average and SD for the lot in question. That is just helpful to roughly show the center of a sorting by weight and what to expect for the spread of the sorting since you would end up with roughly SD x 6 = ES.

Collect as many of the tails of the curve into a sub group as possible to populate a test. Say at least 5 of each of the extreme tails.

You can decide to keep the whole batch sorted or just keep these two extreme sub groups, but you will want to sort them on a table by weight bin till you make your decision. For this test, you will want to make it easy to find the heaviest and the lightest five samples.

The vast majority of the cases will fall into the middle 4 SDs, with far fewer falling into the -3SD and +3SD weight range.

If you can't find at least 5 for each of the two extreme bins, you pull a few from the ones next to them till you do get 5 of each tail. Record the weights of those two sub groups so you can start to understand both what to expect from brass batches and the answer to your original question.

Now you load up those two subsets and go test for group and velocity.

You will now be able to answer if the difference between those two was enough to bother with weight sorting, and you will also start getting an idea of how the QC is running on brass batches over time.

Smaller case volumes are more sensitive than larger ones. For example, if I pull 30 samples out of a batch of 223 and the ES is only around 3 grains, I don't do anything more. That value climbs with bigger cases. Notice that the examples in that chart above have some batches with an ES above 3 grains and some with ones well below. Buy good brass, shoot more and sort less. YMMV

Ned Ludd

Silver $$ Contributor

When prepping new cases or evaluating one brand over another we often mention consistency in weight- what would be an acceptable variation in case weight over a particular batch?

One way to approach this question with a minimum number of loaded/fired rounds is simply to choose about 5 cases from each end of the weight spectrum (i.e. both extreme low and extreme high weights from within the total range). Load them identically in terms of charge weight, seating depth, primer, etc., then determine an average velocity for the "light" and "heavy" groups for direct comparison. Be sure to load a few extra foulers to get the barrel ready before measuring velocity. That should give you a pretty good idea of the total effect on weight (volume) variance across the weight distribution within your specific Lot# of brass. It will also give you some idea of whether sorting brass by weight will actually make a measurable difference in terms of more consistent velocity (i.e. whether you will actually benefit from weight sorting brass at all), and if so, what the appropriate increment for your weight sorting groups might be.

As has already been noted, the effect of brass weight/volume variance increases as the cartridge volume gets smaller. That means there is no "one size fits all" in terms of an acceptable amount of weight variance between cartridges of differing volume. Determining average velocity using low/high extremes within the weight distribution will provide the answer you're looking for.

What is a reasonable case weight for some of the "heavier" calibers?

Using 93 grains for .223, what is normal for some of the bigger ones?

Maybe twice the .223? (except for the really big ones).

One thing we are NOT talking about (so far) is loading the lighter cases with more powder than the heavier cases. What you end up with is some more SPACE, that reduces load density a little.

3% brass weight high to low (not across brands) on a .223 case is about 1/8 of that in space.

Maybe 0.1 to 0.2 grains of real capacity (most powders/water).

But that is empty space. Less than a 1% change in load density. Not charge.

Now, something like a .223AI changes space a lot more (8% ? ) with the same weight of a regular .223. Charges are usually increased for this big a change in space with a higher resulting velocity.

Using 93 grains for .223, what is normal for some of the bigger ones?

Maybe twice the .223? (except for the really big ones).

One thing we are NOT talking about (so far) is loading the lighter cases with more powder than the heavier cases. What you end up with is some more SPACE, that reduces load density a little.

3% brass weight high to low (not across brands) on a .223 case is about 1/8 of that in space.

Maybe 0.1 to 0.2 grains of real capacity (most powders/water).

But that is empty space. Less than a 1% change in load density. Not charge.

Now, something like a .223AI changes space a lot more (8% ? ) with the same weight of a regular .223. Charges are usually increased for this big a change in space with a higher resulting velocity.

Last edited:

RegionRat

Gold $$ Contributor

This answer can vary by years/batches and brands of brass.

Over many years and batches of various calibers, you learn that some brands are tighter than others on average, but even Lapua isn't always the same. It can vary in terms of average and ES.

As an example, it took about two years to see some Lapua in 30-06 show up. For several previous years, a typical ES on that brass ran about 1.6 grains. The latest batch of brass is about 3.64 grains. That said, many other brands have been factors higher than this over the years.

So keep in mind, numbers like in that chart above that represent a 223 case with ES numbers from 1.2 to 6.5 grains. That represents ES of roughly 1.3% to nearly 7% by weight for a 223. At roughly above an ES of 3% starts to show up at 600 yards for a High Master shooter in that caliber.

Now if you consider something like the 30-06 I mentioned, the ES as percentages are generally lower at around 0.8% to 1.8% (but can go up for junk brass).

The level of the shooter and the expectations determine what shows up at distance, but lets say it is roughly that same level, roughly 3%, for 600 yards so you won't need to sort good brass but since junk brass can be factors higher you might need to.

As advice to rookies in Highpower I will say you have lots more important things to worry over before you sort good quality brass... but not all brass is good quality...

Getting to Master or HighMaster, you will find time to set your own threshold level, but since these are hard times and you have to use what you can get, to try and be helpful I will throw out a rough number of saying ignore brass at an ES of below 3% by weight till you get rolling. And..

If the brass is really poor quality and has an ES above 3%, then maybe just cut the batch in half above and below the average value. When you can shoot the difference between the two batches, you are ready for a finer sort test and picker level. YMMV

Over many years and batches of various calibers, you learn that some brands are tighter than others on average, but even Lapua isn't always the same. It can vary in terms of average and ES.

As an example, it took about two years to see some Lapua in 30-06 show up. For several previous years, a typical ES on that brass ran about 1.6 grains. The latest batch of brass is about 3.64 grains. That said, many other brands have been factors higher than this over the years.

So keep in mind, numbers like in that chart above that represent a 223 case with ES numbers from 1.2 to 6.5 grains. That represents ES of roughly 1.3% to nearly 7% by weight for a 223. At roughly above an ES of 3% starts to show up at 600 yards for a High Master shooter in that caliber.

Now if you consider something like the 30-06 I mentioned, the ES as percentages are generally lower at around 0.8% to 1.8% (but can go up for junk brass).

The level of the shooter and the expectations determine what shows up at distance, but lets say it is roughly that same level, roughly 3%, for 600 yards so you won't need to sort good brass but since junk brass can be factors higher you might need to.

As advice to rookies in Highpower I will say you have lots more important things to worry over before you sort good quality brass... but not all brass is good quality...

Getting to Master or HighMaster, you will find time to set your own threshold level, but since these are hard times and you have to use what you can get, to try and be helpful I will throw out a rough number of saying ignore brass at an ES of below 3% by weight till you get rolling. And..

If the brass is really poor quality and has an ES above 3%, then maybe just cut the batch in half above and below the average value. When you can shoot the difference between the two batches, you are ready for a finer sort test and picker level. YMMV

but a waste of time for mast as you never DEFINED YOUR USE/SPORT APPLICATIONInteresting replies so far.

I think the replies were meant to be educational.

If you don't need additional knowledge in sorting brass, yes, a waste of time

If you don't need additional knowledge in sorting brass, yes, a waste of time

but a waste of time for mast as you never DEFINED YOUR USE/SPORT APPLICATION

No, I didn't- nor did I say a particular application was in mind- as opposed to an open ended conversation and interesting replies. Thanks for contributing

Another read:

How much case weight variation is significant?

In testing, how much variation in case weight is detectable at 600 or a 1000 yards in a BR/Dasher size case? Or a better question, what is the acceptable tolerance per bin? I have tested it a little and I think I can see .5gr and know I can 1.0gr variation in round robin case weight tests. CW

forum.accurateshooter.com

Effects of Case Weight Variation on Accuracy

I'm starting to load for a .222 Rem. and am using Lapua cases. I weighed about 100 of the cases and found them to vary between about 92.0 and 94.0 grains. At this point, I'm wondering whether this much variation in 5 cases shot for group would cause variations in internal capacity enough to...

forum.accurateshooter.com

Last edited:

Testing various reloading theories gives me good excuse to go out and shoot to see what I can come up with. So, likewise I sorted a box of my .308 Lapua cases by weight (fully prepped 5x fired, trimmed to length, neck turned and primer pockets uniformed):I just start weighing and make columns of like weight in rows light to heavy. In .10, .20, .30, .40 ......

I write weights on little pices of paper for headers as i descover them.

Then i split them in half.

Some of The outliers if there are any on each end become annealing test cases.

In the beginning i had so many weights separated it was ridiculous keeping up with them. By seasons end i had them mixed all up.View attachment 1316240

This was a start. Soon became a table full.

And as you can see the weights ranged from 172.0 to 174.9 grs. What I was interested in was the issue of the all important "consistency" and rather than comparing the few outliers on both ends, I took the two columns with the most cases (the 5th and 6th from the left for one group and the 3rd and 4th from the right for a second group) and loaded with with my best recipe, keeping the two groups separate, and shot them to see what that consistency might produce. As I anticipated, both groups produced very low SD's, like in the mid single digits, and ES's, like in the very low teens) as well as nice tight groups (significantly better than my normal numbers from not sorting). Apparently, I've somehow lost the actual data on those or I'd share it. I do recall too that there was some difference in velocities between to two groups, but I don't recall how significant. Afterwards, I loaded up the outliers (those columns at both ends) to see the difference, and as expected again, there was a substantial difference in MV's. This convinced me that sorting can make a significant difference in SD's by weeding out those outliers. After all, it's those few outliers that can easily throw off your ES's.

Last edited:

Similar threads

- Replies

- 40

- Views

- 3,772

- Replies

- 60

- Views

- 3,995

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.