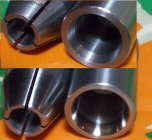

I love my honed Forster dies. But I'm wondering if there's a smarter way to use them than what I have done so far.

I had my 223 die honed to .245. It gives the desired neck tension with all the brass I use and works great with or without the expander (not litigating that aspect here). I'm wondering if the smarter way is to have honed to the largest size they will do (.248) and use it like a body without the expander and consider it a "rough sizer" for the neck.

Then, having done most of the neck reduction in a nicely concentric Forster, you can final size the neck after annealing (or not) with a LCD or a bushing die if it's not enough tension. And in the unlikely event it's too much tension, you hit it with the mandrel die.

Since Lee offers custom LCD mandrel sizes for less than what most bushings can be had for, and the LCD is itself very modestly priced, I think you could end up with a superb sized brass with just two steps-- a coarse sizing and shoulder bump with the honed Forster, then set the final neck tension with the LCD using the mandrel of your preferred size.

This also keeps all of the neck errors on the OD because the final sizing is on a mandrel so the ID of the neck should be nice and round and consistent.

I know lots of folks are happy with the Redding body die and LCD approach. But I think replacing the body die with a honed Forster at max neck ID could improve that technique even more by asking the LCD to do less reduction.

Thoughts?

I had my 223 die honed to .245. It gives the desired neck tension with all the brass I use and works great with or without the expander (not litigating that aspect here). I'm wondering if the smarter way is to have honed to the largest size they will do (.248) and use it like a body without the expander and consider it a "rough sizer" for the neck.

Then, having done most of the neck reduction in a nicely concentric Forster, you can final size the neck after annealing (or not) with a LCD or a bushing die if it's not enough tension. And in the unlikely event it's too much tension, you hit it with the mandrel die.

Since Lee offers custom LCD mandrel sizes for less than what most bushings can be had for, and the LCD is itself very modestly priced, I think you could end up with a superb sized brass with just two steps-- a coarse sizing and shoulder bump with the honed Forster, then set the final neck tension with the LCD using the mandrel of your preferred size.

This also keeps all of the neck errors on the OD because the final sizing is on a mandrel so the ID of the neck should be nice and round and consistent.

I know lots of folks are happy with the Redding body die and LCD approach. But I think replacing the body die with a honed Forster at max neck ID could improve that technique even more by asking the LCD to do less reduction.

Thoughts?