Hello

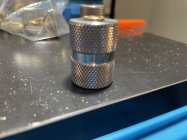

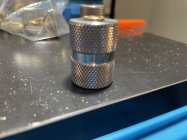

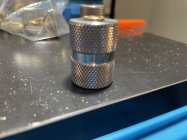

My name is Rob and I'm new to reloading and started using my Dillon 550C that my wife got me. I've loaded a little more than 1,000 rounds of 9mm so far and everything shoots great. I'm using Berry 115gr RN bullets and Accurate #2. I'm using Lee Precision Dies and find them pretty easy to use. My only problem is every now and then my 9mm cartridge is out of spec when I do quality control. The 9mm cartridge would stick out a tiny bit in lynnann chamber gauge. The brass fits fine in the chamber gauge until the bullet seating stage. After stage 3 i would check the cartridge and this is what I get (picture below) Now this happens like once or twice out of 50 rds or so. Any idea what's causing this. I also load 45acp and never encountered this problem. Any help is appreciated, Thanks!

So they all loaded,fired,extracted properly? Or are you culling out the rounds that fail your qc check? A black marker on a poor fitting round could show you where the fit issue is. A taper crimp die can help the odd round that has a case mouth flare issue. Does this occur using premium jacketed bullets? The gage is minimum spec, so the ammo may still run fine through the firearm.

So they all loaded,fired,extracted properly? Or are you culling out the rounds that fail your qc check? A black marker on a poor fitting round could show you where the fit issue is. A taper crimp die can help the odd round that has a case mouth flare issue. Does this occur using premium jacketed bullets? The gage is minimum spec, so the ammo may still run fine through the firearm.

I am removing the rounds that fail my qc check however when I do load those rounds that fail QC into my pistol. They chambered fine but have a hard time extracting. I do use a crimp die in stage 4. I have only used Berry’s RN bullets so far.

I checked 500 that I recently loaded. There were 14 that didn't drop into the gauge. I shot them separately from the rest at a target. All functioned properly.

Post a pic of the culled rounds so the whole cartridge can be seen including crimp.

Post a pic of the culled rounds so the whole cartridge can be seen including crimp.

-

4B1D2EA4-B721-47AA-89D6-87D2467BB7D9.jpeg

417.4 KB

· Views: 62

-

C33B5D78-4515-4B4F-B7B1-48EC0BF99EDD.jpeg

462.6 KB

· Views: 62

-

8E9FE7F4-1F80-40C0-99E2-A3A073258F86.jpeg

507.2 KB

· Views: 57

-

9BB6F11D-3C23-4A50-86FB-0DFF964A9FE5.jpeg

424.6 KB

· Views: 64

I am removing the rounds that fail my qc check however when I do load those rounds that fail QC into my pistol. They chambered fine but have a hard time extracting. I do use a crimp die in stage 4. I have only used Berry’s RN bullets so far.

Are the cases that fail QC the same head stamp as the ones that pass? Some cases have thicker sidewalls than others. In this case, the diameter of the loaded round can be too big.

Have you actually fired any of the failed rounds? If so, do they eject OK?

First I drink the coffee, then I do the things.

Gold $$ Contributor

"The brass fits fine in the chamber gauge until the bullet seating stage."

So...........since you seem to be checking them after sizing and they're OK, then it has to be a crimp thing.

Are the cases that fail QC the same head stamp as the ones that pass? Some cases have thicker sidewalls than others. In this case, the diameter of the loaded round can be too big.

Have you actually fired any of the failed rounds? If so, do they eject OK?

I’ll check. Maybe I’ll fire some of these failed QC rounds in my cheap pistol to see if they work and go from there.

"The brass fits fine in the chamber gauge until the bullet seating stage."

So...........since you seem to be checking them after sizing and they're OK, then it has to be a crimp thing.

The failed ones were right after the bullet seating stage, stage 3.

First I drink the coffee, then I do the things.

Gold $$ Contributor

Hello

My name is Rob and I'm new to reloading and started using my Dillon 550C that my wife got me. I've loaded a little more than 1,000 rounds of 9mm so far and everything shoots great. I'm using Berry 115gr RN bullets and Accurate #2. I'm using Lee Precision Dies and find them pretty easy to use. My only problem is every now and then my 9mm cartridge is out of spec when I do quality control. The 9mm cartridge would stick out a tiny bit in lynnann chamber gauge. The brass fits fine in the chamber gauge until the bullet seating stage. After stage 3 i would check the cartridge and this is what I get (picture below) Now this happens like once or twice out of 50 rds or so. Any idea what's causing this. I also load 45acp and never encountered this problem. Any help is appreciated, Thanks!

View attachment 1403575View attachment 1403574

Berry's bullets are .356" diameter. Larger than jacketed .355" 9mm bullets.

It appears you've applied too much bell to the mouth before seating, then the amount of crimp you've adjusted for isn't wiping it out.

One of the issues with plated bullets, crimping. To little with too much flare, possible extraction problem with unfired round(rounds may fire and extract fine). Too much crimp and you will see marks on target from plating debris(15-20') you want to avoid this(accuracy and bore cleaning). I have found this issue with 38/357, 9mm the odd one that doesn't drop in the cartridge gage gets just a bit more crimp.

skip the gauge and use the bbl of your gun. the gauge is a standard, your gun is what counts, and yes it looks like belling and crimping needs some fine tuning

First I drink the coffee, then I do the things.

Gold $$ Contributor

The failed ones were right after the bullet seating stage, stage 3.

There's really no reason to gauge them until after you crimp them, as long as you're sizing them enough.

Id run my crimp down a quarter of a turn and see what happens. Doug

could be those pieces of brass are at or near max case length and your seating die is possibly starting to engage the crimp? maybe back the seating die out another 1/4 turn and readjust the seating plug and try some more. assume since you are using a seperate crimp 4th die this is lee dies with the factory crimp die?

If your barrel says they are ok but you gauge days different. That means your gauge is tighter than your barrel.

Stop using the gauge and use your barrel instead.

The gauge appears to have tighter dimensions than your chamber...common...but I use the gauge to spot check and set up, also the barrel...and the cartridges are really loose in the Glock chanber...and feed great.

I only use jacketed bullets in all 9 mm and 380 ACP loads, buy in bulk cheap, experienced trouble in an AR barrel that wouldn't feed bullets over .3554" (Cast and plated run into .356"or slightly over area.) So I bought a chamber reamer...

I use a Lee factory crimp die with a carbide resize ring, so case bullet bulges are ironed out enough to chamber 100%.

The case bell doesn't appear to be completely taken out to the bullet surface in one picture...a little air gap. They should all have a nice light taper crimp.