^^^ This is your best advice, start with potential clearance issues and if that is not the problem eliminate and move on.

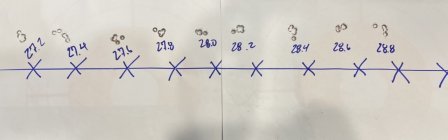

What is the OD neck measurement of a loaded round?

What is the OD neck measurement of a fired case?

What is the length of your case and do you feel any resistance chambering an empty case when you close the bolt?

What is the OD neck measurement of a loaded round?

What is the OD neck measurement of a fired case?

What is the length of your case and do you feel any resistance chambering an empty case when you close the bolt?