BillC79

Gold $$ Contributor

I am posting some of my data that may be of interest to others.

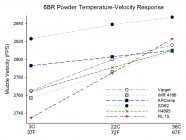

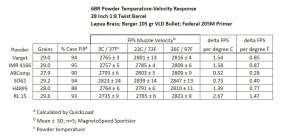

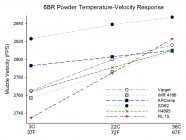

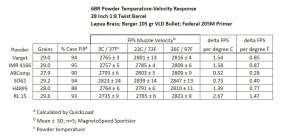

It is time for me to work up a match load for my re-barreled 6BR rifle. I want to use a powder other than Varget and screened several powders for velocity responses across the temperature range I normally shoot in North Central and Central Florida (40F to 95F). Temperatures during a match can easily vary 30 to 35 degrees F.

I selected among powders I had on hand as well as Reloader 15 which is a favorite among other 6BR shooters.

I used methods from my other powder temperature sensitivity studies with .308 Win (link) and 223 Remington loads (link) as well as other 6BR tests (link).

Results are summarized below. ARComp gave the flattest temperature-velocity response across my normal shooting temperatures. Lovex S062 (Shooters World Precision Rifle Powder) gave the second best response, although shot to shot variability was higher than that for other powders.

Comments/suggestions are appreciated. Thank you for looking.

Addendum: March 30, 2022 @ 6PM EDT

Specific Methods for the above data were posted HERE.

It is time for me to work up a match load for my re-barreled 6BR rifle. I want to use a powder other than Varget and screened several powders for velocity responses across the temperature range I normally shoot in North Central and Central Florida (40F to 95F). Temperatures during a match can easily vary 30 to 35 degrees F.

I selected among powders I had on hand as well as Reloader 15 which is a favorite among other 6BR shooters.

I used methods from my other powder temperature sensitivity studies with .308 Win (link) and 223 Remington loads (link) as well as other 6BR tests (link).

Results are summarized below. ARComp gave the flattest temperature-velocity response across my normal shooting temperatures. Lovex S062 (Shooters World Precision Rifle Powder) gave the second best response, although shot to shot variability was higher than that for other powders.

Comments/suggestions are appreciated. Thank you for looking.

Addendum: March 30, 2022 @ 6PM EDT

Specific Methods for the above data were posted HERE.

Last edited: