This problem describes my experience with a Savage, and I think is pretty common in a 6BR built on a factory action. What is the recommended course of action for a Savage bolt head with this problem? Does the whole bolt assembly need to be bushed / hand fitted, or can the bolt head be swapped out for something cut to better tolerances, like a PTG bolt head?

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6.5 Creedmoor Primers Burning Through

- Thread starter treillw

- Start date

carlsbad

Lions don't lose sleep over the opinions of sheep.

Re: Savage. You can swap out the bolt head but custom bolt heads aren't cheap and you'll still need a small firing pin. Most just send them to me or another bushing specialist.

Yes, 6BR is one of the worst cartridges for cratering and blanking of primers.

--Jerry

Yes, 6BR is one of the worst cartridges for cratering and blanking of primers.

--Jerry

Jerry what is an average cost to have a firing pin bushed?Re: Savage. You can swap out the bolt head but custom bolt heads aren't cheap and you'll still need a small firing pin. Most just send them to me or another bushing specialist.

Yes, 6BR is one of the worst cartridges for cratering and blanking of primers.

--Jerry

Robert Weidler

Gold $$ Contributor

A quick check with QuickLoad shows using 38g Var and 147 ELD gives a max pressure under 60K (don't go higher ) with a velocity of 2700. I'm with those that suggest you get your bolt bushed to 0.062 - 0.065. The problem will go away.Hello,

I'm wondering what the thickest primer is to use for a 6.5 Creedmoor with Lapua Brass using small rifle primers?

I'm shooting 147 eldms with varget. I did some pressure testing and got a max powder charge of 38.5 grains.

39 grains gave me 2729 fps

40 grains gave me 2817 fps

During testing, I saw no pressure signs on the primers, only had a mild extractor mark, and no hard bolt lift. So I backed off to 38.5 as a safe max, based strictly on velocity.

I shot a bunch of rounds with 38 grains of powder, giving me a little over a quarter minute at 400 yards. Tickled. I used up all those primers and went and bought 1500 more of the same kind- CCI #450. I loaded up some more bullets.

Before hunting season I had the gun out for a bit of practice with my golden 38 grain load. As I was shooting through the 10 or 15 that I had loaded up, I noticed that a couple of the primers were burning through. Well I guess I must be over pressure I thought and headed home.

So I loaded up some with 37 grains of varget and took them out to the range a couple of days ago. The are burning through as well. What the heck?

The only thing I can think of is that the new batch of primers aren't as strong as the old ones I had, even though they are both CCI 450. Anybody else run into this?

Are there any primers out there that are thicker than the CCI 450?

I also need to break out the chronograph again and check my velocities.

Thanks!

Jerry, Thanks for taking the time to write that explanation on the diameters of firing pin holes."Bushing the firing pin" is a process to make the firing pin hole smaller. It isn't the clearance between the firing pin and the hole in the boltface that is the problem, it is the diameter of the hole. The force causing the primers to extrude is the pressure inside the case times the area of the circular hole. If you reduce the hole diameter, the force decreases by the square of the diameter. Experience has shown that the .080-.085" diameter holes in common OEM bolts crater badly, .070 used in a lot of customs is usually acceptable, and .060-.062 used in bushing almost always totally eliminates the problem.

To bush a bolt the center of the bolt is drilled out and an insert permanently installed. It is precision bored to a new, smaller diameter, usually around .062". Then the firing pin is turned or ground to a new diameter that allows for .001 to .002" clearance.

--Jerry

Very useful information that I will take a note of.

Farmerboy78

Silver $$ Contributor

A quick check with QuickLoad shows using 38g Var and 147 ELD gives a max pressure under 60K (don't go higher ) with a velocity of 2700. I'm with those that suggest you get your bolt bushed to 0.062 - 0.065. The problem will go away.

If that's shown to be max pressure, it may actually be too much for this particular rifle. I've never used varget for anything heavier than a 123gr.

fyrewall

Banned

I had this problem 1 time using CCI 400 primers in a .17 Rem. More than blanking occurred, portions of the primer were blown into the hole in the bolt face and prevented the firing pin from passing through the hole in the bolt face. Worked just fine, (1000 plus rounds more) upon switching to CCI 450's after cleaning inside of bolt & bolt face hole with solvent, a blast of compressed air & a pipe cleaner.

Edit:

Measurement of the hole is/was .073, pin .071 -Ruger M77, MKII

Edit: I measured the hole with the back end of a drill, spinning & polished it until a tight fit in the hole then measured the diameter of the drill.

I also have a 6.5X47 Lapua that I use with 40 grains of H4350 & 130 Nosler RDF that is near max load manual data (40.5 g., H4350, Hodgdon data for 130 Sierra Tippled MK) with CCI 41 primers. Slight cratering observed, primer strike is not centered & slight cratering appears only towards center of primer. Near same hole/pin dimensions as other rifle which was a .17 Rem & now a .20 P. used with Zippy loads.

Edit:

Measurement of the hole is/was .073, pin .071 -Ruger M77, MKII

Edit: I measured the hole with the back end of a drill, spinning & polished it until a tight fit in the hole then measured the diameter of the drill.

I also have a 6.5X47 Lapua that I use with 40 grains of H4350 & 130 Nosler RDF that is near max load manual data (40.5 g., H4350, Hodgdon data for 130 Sierra Tippled MK) with CCI 41 primers. Slight cratering observed, primer strike is not centered & slight cratering appears only towards center of primer. Near same hole/pin dimensions as other rifle which was a .17 Rem & now a .20 P. used with Zippy loads.

Last edited:

Carlsbad do you bush hardened bolts?

I had a bolt sent back by another well-respected ‘smith, with a note that he won’t do this with case-hardened bolt faces such as mine (RPA Quadlite).

Came as a surprise as he’d done one for me a few years ago, solved the cratering problem, worked fine ever since.

I had a bolt sent back by another well-respected ‘smith, with a note that he won’t do this with case-hardened bolt faces such as mine (RPA Quadlite).

Came as a surprise as he’d done one for me a few years ago, solved the cratering problem, worked fine ever since.

carlsbad

Lions don't lose sleep over the opinions of sheep.

I had this problem 1 time using CCI 400 primers in a .17 Rem. More than blanking occurred, portions of the primer were blown into the hole in the bolt face and prevented the firing pin from passing through the hole in the bolt face. Worked just fine, (1000's of rounds more) upon switching to CCI 450's after cleaning inside of bolt & bolt face hole with solvent, a blast of compressed air & a pipe cleaner.

Edit:

Measurement of the hole is/was .073, pin .071 -Ruger M77, MKII

.073 is one of those borderline diameters that is usually ok for moderate loads. Changing primers moved you across the line but you can see that you're very close. If you ever want to switch primers or move to a hotter round, bushing will allow that.

--Jerry

topclass2017

Gold $$ Contributor

Yes, 6BR is one of the worst cartridges for cratering and blanking of primers.

--Jerry[/QUOTE]

Curious as to why 6BR is one of the worst for cratering...

--Jerry[/QUOTE]

Curious as to why 6BR is one of the worst for cratering...

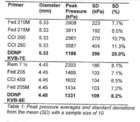

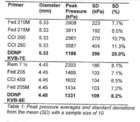

When you say 'burning through', do you mean like the one in the centre of the pic below? If so, that's not pressure burning through, it's what's called 'blanking' and usually results from an over-large firing pin tip allied to a poor fit in the bolt-face allied to a Small Rifle type primer (srp).

So, the second question is what action are you using? Some factory actions blank every srp primer going when you get much above starting load pressures. The one that produced this blanked primer is an FN SPR (Winchester Model 70 action) that had been rebarreled to 6.5X47 Lapua and did just this. It was promptly rechambered to 260 Rem whose Large Rifle (lrp) size primers solved the problem.

So why srp problems and not in lrp? I can't tell you why, but that's the way things pan out. There are three possible answers to your problem if it has bolt/firing pin causation: 1) use a harder primer with a thicker cup - but that's not much help here as the CCI-450 SRM primer has the heavier 0.025" cup and is about as tough a small primer as you'll get; 2) send your bolt off to Gre-Tan Engineering or one of the other gunsmiths who turn the pin down and fit a bushing with smaller diameter hole intro the bolt-face; 3) in your case as you're3 loading 6.5mm Creedmoor you have the choice of brass with both primer sizes. So put the Lapua srp stuff to one side and get Hornady, Starline, Norma, Peterson or whoever lrp cases.

View attachment 1147615

Looking at your primers, they still have rounded edges and not totally flat, so I'd say your load while fairly hot, is not over the top hot. Still though, you're blanking primers so first place to look at is the fit of the firing pin to the bolt head.

Although you can use a micrometer to measure firing pin dia and get to within a few ten thousandths, firing pin holes are more difficult to measure unless you have some very nice equipment. So I use drills or drill blanks inserted into the firing pin hole, and then mic the one that's the closest fit. You might do this just for the experience, if nothing else.

I had a new Savage .223 that blanked everything I ran through it. I subsequently found the firing pin to hole clearance was around .007". I ordered a half dozen firing pins from Savage and cherry picked the best fit. Now with only .002 clearance, it was quite happy and only blanks under very high pressure, as it should.

The reason the 223 and 6BR are more prone to blanking is that these calibers typically operate at higher pressures, the 6BR especially which, if I'm not mistaken, is in the 70,000 psi range.

Best fix is to have the bolt head bushed. That way you'll repair any damage done by flame cutting effect of a blown primer, and fix the cause once and for all.

Least expensive fix may be to order parts from the mfg and change out what should never have left the factory in the first place. The Savage firing pins I ordered were only like $3 each. Don't know about Ruger prices.

Last edited:

AckleymanII

Gold $$ Contributor

Varget with 120-129's you can be ok.

Varget with 140g, now you are into bushing your bolt.

Change out to any of the 4350's, you will be OK.

An issue with blanked primers, where did that little center cup go that pierced? I have had them end up in the bolt race ways and in trigger housings!!!!

Varget with 140g, now you are into bushing your bolt.

Change out to any of the 4350's, you will be OK.

An issue with blanked primers, where did that little center cup go that pierced? I have had them end up in the bolt race ways and in trigger housings!!!!

37 grs of powder is still over maximum, when comparing lighter weight bullets of different brands on Hodgdons website.

The brass your using is different then Hodgdon. Possibly making more pressure.

Reduce the powder charge.

The small primer your using may change pressure also?

https://discover.dtic.mil/results/?q=Primers large or small See Untitled link.

High speed measurement of firearm primer blast waves.

The brass your using is different then Hodgdon. Possibly making more pressure.

Reduce the powder charge.

The small primer your using may change pressure also?

https://discover.dtic.mil/results/?q=Primers large or small See Untitled link.

High speed measurement of firearm primer blast waves.

Last edited:

Or this link for primer output. https://discover.dtic.mil/results/?q=High speed measurement of firearm primer blast waves.

Lower on the search page.

Lower on the search page.

Powder Lot Variations: A Case Study with H4831 – Hodgdon Extreme

Last edited:

I have solved this issue in an AR (known good load, primers piercing at the pin) by removing the burr on the end of the pin (it was really small, but enough) and adjusting the FP protrusion down to match a known good rifle.It looks to be what you are describing - blanking.

I think you have a pin problem; solve it in the gun.

For me i have noticed that fed 210m primers have a softer cup.

I KNOW my load of h4350 is not a hot load in my light gun but other shooters said my primers were "cupping" or cratering due to the load.

Never had a pierced primer ( except for load development) but to look at the primer youd think the load was getting to hot.

A well known 1000 yd ibs shooter told me that the 210m were notorious for This.

I changed from fed 210m to cci br primers with exact powder load and poof.

It went away and got my es into single digits.

A simple primer change may fix this.

I KNOW my load of h4350 is not a hot load in my light gun but other shooters said my primers were "cupping" or cratering due to the load.

Never had a pierced primer ( except for load development) but to look at the primer youd think the load was getting to hot.

A well known 1000 yd ibs shooter told me that the 210m were notorious for This.

I changed from fed 210m to cci br primers with exact powder load and poof.

It went away and got my es into single digits.

A simple primer change may fix this.

Don't think it is dangerous, but it can also cause a little disc, cut from the primer to be blown into your bolt. A few of these discs inside the bolt will cause you some bigger problems. These little discs can also fall into your trigger area, depending on your rifle type.Is it dangerous to shoot the gun with loads that are doing this? Any danger of the gas blowing into your eyes?

The rifle is a ruger precision. A new firing pin wouldn't help things? Think ruger will do anything about it?

Here is a little primer story. Many moons ago (around 40 years), up late, reloading long after I should have gone to bed, I overloaded some .30-06 loads with, I believe it was 748. This was for a double heat treat '03 Springfield that had been fitted with a new '03-A3 bolt, and that with the heaviest firing pin that strong hands could assemble to the pin.

When I fired the first overloaded round smoke came out of the action and when I opened the bolt, the primer fell out of its pocket that was so enlarged that it looked like it would take a shotgun primer. The primer was in one piece and when I examined it, it had neither a crater nor was it pierced.

I believe the reason was that government spec's were tight as to the diameter of the FP hole and the shape of its edge, which was not chamfered. The tip of the firing pin was an excellent fit for the hole. Beyond that, those of you who have looked at a Springfield striker assembly know that it has one of the heaviest firing pins, and that combined with the non stock very heavy spring kept the pin from being backed up as the pocket was being expanded by the over pressure load. The pin tip diameter is not less than that which is common in factory rifles today. The tip of the pin was machined as a perfect hemisphere.

With a lighter pin and spring, a hole that is a poor fit that has been chamfered during manufacturing, warm loads can back up the pin so that the taper of the pin tip is within the hole and this increases the gap to the point that primer cup material can flow into it and form a crater.

As an aside Holland's Shooters Supply offers a 700 firing pin with and oversized tip to be fitted to a closer fit to the factory bolt hole.

None of this is to say that you should not have Carlsbad bush your bolt's firing pin hole to a smaller diameter and better fit. All reports are that he does top quality work and gives excellent service at prices that are quite fair.

I have some experience with a .062 firing pin that has the proper fit in a properly done hole, by virtue of owning Stiller Viper, and Bighorn actions. From that experience I can report that that pin diameter coupled with a proper hole is a very good way to go, although if done perfectly, as in many custom actions, the diameter that you can can work very well.

When I fired the first overloaded round smoke came out of the action and when I opened the bolt, the primer fell out of its pocket that was so enlarged that it looked like it would take a shotgun primer. The primer was in one piece and when I examined it, it had neither a crater nor was it pierced.

I believe the reason was that government spec's were tight as to the diameter of the FP hole and the shape of its edge, which was not chamfered. The tip of the firing pin was an excellent fit for the hole. Beyond that, those of you who have looked at a Springfield striker assembly know that it has one of the heaviest firing pins, and that combined with the non stock very heavy spring kept the pin from being backed up as the pocket was being expanded by the over pressure load. The pin tip diameter is not less than that which is common in factory rifles today. The tip of the pin was machined as a perfect hemisphere.

With a lighter pin and spring, a hole that is a poor fit that has been chamfered during manufacturing, warm loads can back up the pin so that the taper of the pin tip is within the hole and this increases the gap to the point that primer cup material can flow into it and form a crater.

As an aside Holland's Shooters Supply offers a 700 firing pin with and oversized tip to be fitted to a closer fit to the factory bolt hole.

None of this is to say that you should not have Carlsbad bush your bolt's firing pin hole to a smaller diameter and better fit. All reports are that he does top quality work and gives excellent service at prices that are quite fair.

I have some experience with a .062 firing pin that has the proper fit in a properly done hole, by virtue of owning Stiller Viper, and Bighorn actions. From that experience I can report that that pin diameter coupled with a proper hole is a very good way to go, although if done perfectly, as in many custom actions, the diameter that you can can work very well.

Similar threads

- Replies

- 10

- Views

- 2,154

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.