LuckyGunner and Ultimate Reloader have excellent articles on this.Has anyone seen a maximum pressure rating on a firearm's chamber and bolt? Not trying to argue either side, just curious. I know and can read the pressure statements in reloading manuals. Have seen all the warnings on the 556/223 debate. But honestly in a 223 FTR 7 or 6.5 twist I am sure the pressure for a 90 grain bullet touching the lands would exceed 556 pressure. Not trying to pick a side but just wondering.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RegionRat

Gold $$ Contributor

Usually, the brass cartridge case will fail before we have a catastrophic failure of the gun, and that is not a bad thing.Has anyone seen a maximum pressure rating on a firearm's chamber and bolt? Not trying to argue either side, just curious. I know and can read the pressure statements in reloading manuals. Have seen all the warnings on the 556/223 debate. But honestly in a 223 FTR 7 or 6.5 twist I am sure the pressure for a 90 grain bullet touching the lands would exceed 556 pressure. Not trying to pick a side but just wondering.

So what you are really asking, is what is the recommended safe max pressure for the brass.

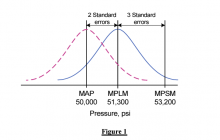

Before we go too far, you have to understand that catastrophic case failures have a mean and a dispersion around them just like a lot of things.

The text book yield strength and ultimate strength of metals also has an average with noise around it.

The ammo specifications quote how the pressure statistics are defined, and how the coefficient of variation is viewed. So even normal ammo has a statistical pressure distribution that has high end "tail on the curve".

It looks something like this in general.

You can start to see some failures early (lower stress) then more and more before you even get to that average. This is why safety margin exists in design philosophy.

It is far easier to design for safety margin in pressure events, than it is to predict the exact points of failure.

So you will never get a clean answer to your question because we try to keep a healthy safety margin away when we give you that "maximum". In this way, you should never see a failure even when you touch onto that maximum pressure.

Typically, you will see a yield in the case head to the point where it may not hold a primer or re-size. That typically happens 25 - 35 KSI lower than the next level of failure where the case may leak or rupture.

Much also depends on the design of the gun, since the chamber and bolt are trying to contain the case but they also flex. Different pistol designs have shown this behavior when the feed ramps leave too much unsupported brass. Those cases fail before the chamber or bolt as an example that is easy to study.

It isn't unusual to hit 70 - 72 KSI in proof pressure load testing for 223/556, but that brass is toasted in that one cycle. For perspective that is roughly 40% higher than the typical max recommended load pressure of 50 - 55 KSI. Take it another 30 or 40% higher and the brass typically ruptures and primers leak or blow.

I thi

I think what he meant is that the .556 brass is not what is being overworked here - it is the rifle. There would likely be no indications of the .556 brass being over-pressured - because it is not. It is the potential of what the heavier charge "could" do to the rifle."Of course you can't find pressure signs on brass or primers?" Did you just really say that!?

Umm...I know this whole post has gotten pretty long but you should read it further.I thi

I think what he meant is that the .556 brass is not what is being overworked here - it is the rifle. There would likely be no indications of the .556 brass being over-pressured - because it is not. It is the potential of what the heavier charge "could" do to the rifle.

There is no danger in shooting my .223 rifle with 5.56 ammo.

It is now Dec. 2023 and I've shot hundreds of 5.56 ammo through it including many of my reloads.

I did a pretty thorough research job and found a couple of very thoroughly researched websites that go into this long lasting debate. It has been debunked as far as I'm concerned.

I don't argue that many rifles chambered in .223 can't "safely" shoot 5.56 ammo. That many barrel manufacturers and reloading manuals say not to, should not be completely disregarded. It depends on the chamber and the load. Some chambers (maybe yours?) are cut in such a manner as to be relatively safe with the load you are shooting. Some not. I was merely clarifying what the other readers intent was in what he said. You are free to disagree. It always becomes a debate because some folks will shoot 5.56 in their rifle, learned that it did not blow up - and therefor feel it is O.K. Do they know what the pressures are in their chambers? Likely not. Without knowing what those pressures are, ignorance is bliss as long as things are humming along. I do know that I've seen a few .223's blow up at the range shooting .556 factory ammo. So - what may be "safe" in your rifle may not be in another's. It is good that you did such thorough research. Did you ask companies like Krieger and other barrel manufacturers why they say to not use 5.56? Or maybe ask the powder companies why they provide different load data for .223 vs. 5.56? Perhaps they are all messed up and don't know how to effectively research what they are doing?? Not arguing your point - just wondering how the powder and barrel manufacturers can all be wrong as opposed to your research........ It all depends on the chamber and load......And they do differ. A lot of .223 chambers are cut with a Wylde chambering, which are forgiving of the use of 5.56, even though they say not to shoot .556. True match .223 chambers are another story.Umm...I know this whole post has gotten pretty long but you should read it further.

There is no danger in shooting my .223 rifle with 5.56 ammo.

It is now Dec. 2023 and I've shot hundreds of 5.56 ammo through it including many of my reloads.

I did a pretty thorough research job and found a couple of very thoroughly researched websites that go into this long lasting debate. It has been debunked as far as I'm concerned.

Last edited:

I've said this many times already.

The data that you see in most if not all manuals that provide data for 5.56 in its own section vs 2.23 sections overlap considerably.

If 5.56 and 2.23 ammo were tested in the same manner there is no difference but THEY ARE NOT!

That's why people think 5.56 is a hotter load. IT IS NOT!!!

The data that you see in most if not all manuals that provide data for 5.56 in its own section vs 2.23 sections overlap considerably.

If 5.56 and 2.23 ammo were tested in the same manner there is no difference but THEY ARE NOT!

That's why people think 5.56 is a hotter load. IT IS NOT!!!

Infrequent Shooter

Gold $$ Contributor

I found this on youtube. I don't know how accurate it is.

Most likely a steel core green tipped round was used to make the hole on the left. I've done the same thing with the same results. I can tell you that if his video is truthful, then I can't explain it. In my test I shot 62gr Hornady FMJBT's using 2460 at 23.6 grs. in Lake City brass and IMI 62gr green tip rounds at 50 yards in a Stag Arms AR15 with a 20" White Oak Armament barrel chambered in .223 Wylde, First test was 2 of the Hornady 62's at a 3/8 thick mild steel plate and neither penetrated. Next was the IMI's and both penetrated easily. The IMI was labeled 5.56. My handloaded Hornady's were hotter than the IMI's. Same results with my Savage Axis II Precision rifle chambered in .223. All were chronographed with a Magnetospeed V3, Don't recall the velocities off hand, The data is in my other laptop which is currently at my buddies house.

I found this on youtube. I don't know how accurate it is.

Last edited:

So, I did something EVERY ONE says NOT TO DO!!!

I shot some 5.56 factory ammo through my Savage Axis Precision Rifle chambered in .223 only!

I used some Sig Sauer 5.56 77gr. Frontier 5.56 68gr. and some IMI 5.56 77 gr ammo.

I checked each round at home using various tools, gages and methods I learned to make sure each and

every round would function safely in my rifle.

There was no hard chambering, bolt lift, extraction, over pressure signs on the primers.

All cases were dimensionally checked and recorded before and after firing and were no

different than my other ammo that I shot that were designated as .223

I slugged the chamber shortly after I got the rifle and re-slugged it after this experiment and found

nothing really changed.

Recoil felt no different nor did it sound any different.

The results from my chronograph showed only a slight increase in velocity.

Best of all the groups were stellar!

***Crickets Chirping***So, I did something EVERY ONE says NOT TO DO!!!

I shot some 5.56 factory ammo through my Savage Axis Precision Rifle chambered in .223 only!

I used some Sig Sauer 5.56 77gr. Frontier 5.56 68gr. and some IMI 5.56 77 gr ammo.

I checked each round at home using various tools, gages and methods I learned to make sure each and

every round would function safely in my rifle.

There was no hard chambering, bolt lift, extraction, over pressure signs on the primers.

All cases were dimensionally checked and recorded before and after firing and were no

different than my other ammo that I shot that were designated as .223

I slugged the chamber shortly after I got the rifle and re-slugged it after this experiment and found

nothing really changed.

Recoil felt no different nor did it sound any different.

The results from my chronograph showed only a slight increase in velocity.

Best of all the groups were stellar!

Danny

ImBIllT

Silver $$ Contributor

Of course you can't find pressure signs on brass or primers. The pressure of the 5.56 is what they are designed for. However the rifle is not.

Have you ever seen someone cut a stone or a brick using a hammer and chisel? They will strike with the hammer repeatedly and then after many blows the stone or brick fractures. With your logic it is the one perfect blow at the last that causes the fracture. I contend that it's the accumulated force of all the blows.

Either way, when your rifle fails, you'll have no liability claim against Savage.

Brass, and steel don’t work that way. Aluminum doesn’t either, but it doesn’t stand up to repeated cycles of stress within the elastic regime as well as steel and brass. That said, the important parts of an AR where pressure is related are made of steel, not aluminum.

To the OP. It seems as though that particular batch of 5.56 ammo is fine in that rifle. Theoretically some 5.56 NATO ammo could definitely be within the pressure spec in a 5.56 NATO chamber while resulting in an substantially higher pressure if fired in a 223 Rem chamber. It seems as though it’s usually fine, but that’s not an endorsement.

Looking at the Savage web page. Its unclear if the chamber is actually a 223 Remington or a now common Wylde chamber that is common in conjunction with the 1:7 twist barrels these days. And you guys all know the Wylde chamber has a longer freebore than a 5.56 Nato freebore which will change the pressure pretty dramatically lower.

Wonder what the chamber actually is.???

Wonder what the chamber actually is.???

RegionRat

Gold $$ Contributor

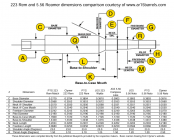

Just some examples of chamber dimensions.

There can be differences in what folks call NATO, Wylde, match, etc..

All means you have to do more homework than what meets the eye....

Use your favorite bullet and check distance to touch lands, rather than accept words and labels that may or may not be actually made to a standard. YMMV

I think you will get away with more with a bolt gun .You cheated death!!!

Greg

I think you will get away with more with a bolt gun .You cheated death!!!

Greg

We

When I make reloads for this rifle I use Quickload under 5.56 ammo. My rifle does just fine with my reloads in both my bolt rifle and my AR.

So, in conclusion, I am convinced that myth of shooting 5.56 ammo in a rifle chambered in .223 is dangerous is just that, a myth.

Well, if you go to the links I provided earlier in this post you'll find that the differences between 5.56 and.223 ammo are that they are measured in different ways. Some of the store bought 5.56 needed to be re-seated to chamber properly. I chronographed both and found no real differences. Some brands were on the high side and others were on the low side.Brass, and steel don’t work that way. Aluminum doesn’t either, but it doesn’t stand up to repeated cycles of stress within the elastic regime as well as steel and brass. That said, the important parts of an AR where pressure is related are made of steel, not aluminum.

To the OP. It seems as though that particular batch of 5.56 ammo is fine in that rifle. Theoretically some 5.56 NATO ammo could definitely be within the pressure spec in a 5.56 NATO chamber while resulting in an substantially higher pressure if fired in a 223 Rem chamber. It seems as though it’s usually fine, but that’s not an endorsement.

When I make reloads for this rifle I use Quickload under 5.56 ammo. My rifle does just fine with my reloads in both my bolt rifle and my AR.

So, in conclusion, I am convinced that myth of shooting 5.56 ammo in a rifle chambered in .223 is dangerous is just that, a myth.

It is not a Wylde chamber it is chambered in .223 Remington. I contacted them and that is what I was told. And it is apparently a somewhat tight chamber, on the low side of SAAMI specs. It shoots bugholes with just about everything I put through it!Looking at the Savage web page. Its unclear if the chamber is actually a 223 Remington or a now common Wylde chamber that is common in conjunction with the 1:7 twist barrels these days. And you guys all know the Wylde chamber has a longer freebore than a 5.56 Nato freebore which will change the pressure pretty dramatically lower.

Wonder what the chamber actually is.???

This rifle is why I also bought it's big brother in .308. Both are amazing!

Nope, no joke.I honestly thought this thread was an april fools joke or something. I guess it wasn't?

Similar threads

- Replies

- 2

- Views

- 3,312

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.