Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

22BR Lapua zero freebore reamer

- Thread starter JSH

- Start date

I used the grizzly reamer with 0.100 freebore. Copy is here:

http://forum.accurateshooter.com/threads/my-new-22br.3981971/#post-37524506

This reamer works very nicely with the Redding 22BR FL dies. You could take this print and ask the reamer maker of your choice to make a zero freebore version for you. Another thing I would do is extend the OAL from 1.555 up to 1.565 so that you don't need to trim the 6BR brass as much after necking it down. The 0.253 neck is a no-turn neck on Lapua brass, with 0.003 - 0.0025 clearance.

http://forum.accurateshooter.com/threads/my-new-22br.3981971/#post-37524506

This reamer works very nicely with the Redding 22BR FL dies. You could take this print and ask the reamer maker of your choice to make a zero freebore version for you. Another thing I would do is extend the OAL from 1.555 up to 1.565 so that you don't need to trim the 6BR brass as much after necking it down. The 0.253 neck is a no-turn neck on Lapua brass, with 0.003 - 0.0025 clearance.

NorCalMikie

Gold $$ Contributor

No mater what reamer you get, MEASURE THE CHAMBER OAL, write that # down and refer to it BEFORE you even think about trimming any brass.

Most reamers are cut about .020 LONGER than the recommended MAX trim length.

And go ZERO freebore. Start off with the lightest bullets you can get your hands on and go heavier as the throat wears

Know that chamber length # going in and you may not have to trim for a LOOOONG time.

And while you're at it, make it a no turn neck so you spend more time pulling the trigger and less time messing with brass.

Most reamers are cut about .020 LONGER than the recommended MAX trim length.

And go ZERO freebore. Start off with the lightest bullets you can get your hands on and go heavier as the throat wears

Know that chamber length # going in and you may not have to trim for a LOOOONG time.

And while you're at it, make it a no turn neck so you spend more time pulling the trigger and less time messing with brass.

Ramblerman

Silver $$ Contributor

Someone buys a throating reamer...the other buys a zero freebore chamber reamer? Hmmmm....Bwahahaha

NorCalMikie

Gold $$ Contributor

I've had experience with both the 6 and 22 BR. Load them both with a "jam" into the lands. The 22 BR WILL take a little more work as it gets pretty touchy and you don't just dump powder like the 6 BR.

Have seen pressure problems with a jump to the lands on both.

XX.X amount of powder and you start seeing pressure signs.

Than same exact load of XX.X loaded with a "jam" into the lands and no pressure signs and, you can go up even higher on the powder with no ill effects.

Go long freebore and you before too long, you won't be able to find a bullet long enough to get close to the lands. Go short from day 1. You can always go longer. YMMV.

Have seen pressure problems with a jump to the lands on both.

XX.X amount of powder and you start seeing pressure signs.

Than same exact load of XX.X loaded with a "jam" into the lands and no pressure signs and, you can go up even higher on the powder with no ill effects.

Go long freebore and you before too long, you won't be able to find a bullet long enough to get close to the lands. Go short from day 1. You can always go longer. YMMV.

Funny, I had a discussion about that very combination yesterday with a certain @JSH.Someone buys a throating reamer...the other buys a zero freebore chamber reamer? Hmmmm....Bwahahaha

I've never done a chamber/throat with separate reamers. I'm guessing the chamber comes first?

Hell, maybe a trip to the north end of ChiTown would be in order...

AlNyhus

Silver $$ Contributor

Have seen pressure problems with a jump to the lands on both. XX.X amount of powder and you start seeing pressure signs.Then same exact load of XX.X loaded with a "jam" into the lands and no pressure signs and, you can go up even higher on the powder with no ill effects.

So....what are you really seeing when this happens?

Last edited:

I used the grizzly reamer with 0.100 freebore. Copy is here:

http://forum.accurateshooter.com/threads/my-new-22br.3981971/#post-37524506

This reamer works very nicely with the Redding 22BR FL dies. You could take this print and ask the reamer maker of your choice to make a zero freebore version for you. Another thing I would do is extend the OAL from 1.555 up to 1.565 so that you don't need to trim the 6BR brass as much after necking it down. The 0.253 neck is a no-turn neck on Lapua brass, with 0.003 - 0.0025 clearance.

I'm working on a 22BR no-neck-turn reamer right now. I had Dave Kiff build me up a 6BR no-neck turn, zero free bore, reamer back in 2005, but we can't find the data sheet, so I'm measuring and researching now, as I want them to match so I can use my same custom Harrel's dies.

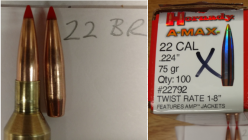

I too was thinking maybe .100 freebore, as I plan to shoo 53 and 55 grain v-max/BlitzKing bullets, and not the lighter 40 v-max. But maybe even then zero freebore would be best. not sure.

My 800 pieces of Lapua 6BR brass measure .013 on the money, so I'm thinking .253 neck should be perfect. Does anybody know how much I can expect my necks to thicken, and lengthen, when going down to 22 Cal?

My current 6br "Actual" chamber length, as cut on my barrel, is 1.579, and I love it, because my brass has never been trimmed and is 1.560-1.564 in length. Thinking maybe a 1.580 length will be good in this case, or may I just go a little shorter, see what I get, and trim once up front.

0.100 freebore is really long for such light bullets. I'd go much shorter if that is your goal. You can see in my linked thread where I've posted pictures of various bullets seated to touching the lands in my gun.I too was thinking maybe .100 freebore, as I plan to shoo 53 and 55 grain v-max/BlitzKing bullets, and not the lighter 40 v-max. But maybe even then zero freebore would be best. not sure.

I wouldn't go 1.580" unless you don't mind scrubbing carbon out of the necks. It has been a while since I have sized some virgin brass, and I trimmed all of mine to fit my chamber, but I definitely didn't cut away 0.030" to get things to fit in my 1.555" chamber. Also consider that a 1.580 length and a 0.100 freebore is like a 0.125" freebore with a "normal" 1.555" chamber.My current 6br "Actual" chamber length, as cut on my barrel, is 1.579, and I love it, because my brass has never been trimmed and is 1.560-1.564 in length. Thinking maybe a 1.580 length will be good in this case, or may I just go a little shorter, see what I get, and trim once up front.

AckleymanII

Gold $$ Contributor

i shot out two barrels with the 22 br with zero freebore, 1.5* leade angle.

I shot the 50g ballistic tips at 3800-+ as one barrel was 23" and the other was 27", both 14 twists.

I turned the necks on my cases.

R#15 with 7 1/2's shot tiny bug holes, I do not remember any issues being difficult to work up a load, perhaps two trips to the rifle range. A friend had others just like mine and he is still shooting them today.

We did not shoot heavy bullets in our barrels

RAG, Your comment:

"I too was thinking maybe .100 freebore, as I plan to shoo 53 and 55 grain v-max/BlitzKing bullets, and not the lighter 40 v-max. But maybe even then zero freebore would be best. not sure."

.100 FB is really bad thinking. I would not go over .030 for 50-55g bullets.

.020 FB would be perfect as a tad bit of freebore may help a little.

I found out in my barrels that when the 50g bullets started jumping over .005, bug hole groups started turning into groups with paper showing between the bullet holes.

53g V max and 55g Sierra blitz kings work best in a 12 Twist.

I shot the 50g ballistic tips at 3800-+ as one barrel was 23" and the other was 27", both 14 twists.

I turned the necks on my cases.

R#15 with 7 1/2's shot tiny bug holes, I do not remember any issues being difficult to work up a load, perhaps two trips to the rifle range. A friend had others just like mine and he is still shooting them today.

We did not shoot heavy bullets in our barrels

RAG, Your comment:

"I too was thinking maybe .100 freebore, as I plan to shoo 53 and 55 grain v-max/BlitzKing bullets, and not the lighter 40 v-max. But maybe even then zero freebore would be best. not sure."

.100 FB is really bad thinking. I would not go over .030 for 50-55g bullets.

.020 FB would be perfect as a tad bit of freebore may help a little.

I found out in my barrels that when the 50g bullets started jumping over .005, bug hole groups started turning into groups with paper showing between the bullet holes.

53g V max and 55g Sierra blitz kings work best in a 12 Twist.

First, I would form the 22BR cases before I would spec the reamer and .100 freebore for those varmint bullets is definitely a big no! Depending upon the average case length I would determine the chamber length and freebore.I'm working on a 22BR no-neck-turn reamer right now. I had Dave Kiff build me up a 6BR no-neck turn, zero free bore, reamer back in 2005, but we can't find the data sheet, so I'm measuring and researching now, as I want them to match so I can use my same custom Harrel's dies.

I too was thinking maybe .100 freebore, as I plan to shoo 53 and 55 grain v-max/BlitzKing bullets, and not the lighter 40 v-max. But maybe even then zero freebore would be best. not sure.

My 800 pieces of Lapua 6BR brass measure .013 on the money, so I'm thinking .253 neck should be perfect. Does anybody know how much I can expect my necks to thicken, and lengthen, when going down to 22 Cal?

My current 6br "Actual" chamber length, as cut on my barrel, is 1.579, and I love it, because my brass has never been trimmed and is 1.560-1.564 in length. Thinking maybe a 1.580 length will be good in this case, or may I just go a little shorter, see what I get, and trim once up front.

Ahhh. You're right, that would be too much Freeborn. With the long necks on BR case, I suppose zero Freebor is the way to go.

And I'll have to order some 22 cal bushings for my 6BR Harrels die. Thinking I should probably get a step down size and do the neck down in two steps to play it safe.

And I'll have to order some 22 cal bushings for my 6BR Harrels die. Thinking I should probably get a step down size and do the neck down in two steps to play it safe.

Does anybody know how much I can expect my necks to thicken, and lengthen, when going down to 22 Cal?

Blue box Lapua necks thicken by very close to 0.002" per side (0.0125" as 6BR, 0.0143" as 22BR). The necks don't get long(er) enough to trim for the reamer that I have.

I had 22cal bushing, but it was for neck turned brass so it necked down too far (oversized), so there was massive neck tension when seating...and the FL bushing die wasn't quite able to reach/size all the way down to bottom of neck. Nevertheless, neck thickness went from .013 to nearly .014 according to my ball micrometer. But once seated with bullet, overall neck diameter was only .250 on the button. I think I'll just go with .253 neck and call it good.

Oh yeah, overall length of this piece of brass grew from 2.563 to 2.573. So I'll probably increase neck length by .020 or .025 over SAAMI, and then depending how how long chamber gets cut, I may or may not have to trim once up front. I might trim and anneal anyhow, since this brass has about 10 firings already.

Below is current 6BR with the 22BR in middle.

Oh yeah, overall length of this piece of brass grew from 2.563 to 2.573. So I'll probably increase neck length by .020 or .025 over SAAMI, and then depending how how long chamber gets cut, I may or may not have to trim once up front. I might trim and anneal anyhow, since this brass has about 10 firings already.

Below is current 6BR with the 22BR in middle.

Attachments

Not to to be picky, but the 22BR is not a SAAMI cartridge.Next, why make the chamber length so excessive? If you went with your max case length plus .025, plus another .014-.016 at the transition into the lead, that’s another .040 of freebore, not to mention a chamber OAL of around 2.598.I had 22cal bushing, but it was for neck turned brass so it necked down too far (oversized), so there was massive neck tension when seating...and the FL bushing die wasn't quite able to reach/size all the way down to bottom of neck. Nevertheless, neck thickness went from .013 to nearly .014 according to my ball micrometer. But once seated with bullet, overall neck diameter was only .250 on the button. I think I'll just go with .253 neck and call it good.

Oh yeah, overall length of this piece of brass grew from 2.563 to 2.573. So I'll probably increase neck length by .020 or .025 over SAAMI, and then depending how how long chamber gets cut, I may or may not have to trim once up front. I might trim and anneal anyhow, since this brass has about 10 firings already.

Below is current 6BR with the 22BR in middle.

AlNyhus

Silver $$ Contributor

^^^^^ This! ^^^^^Not to to be picky, but the 22BR is not a SAAMI cartridge.Next, why make the chamber length so excessive? If you went with your max case length plus .025, plus another .014-.016 at the transition into the lead, that’s another .040 of freebore, not to mention a chamber OAL of around 2.598.

Is there a reason that you want so much extra neck length on your chamber in front of the brass? I use a borescope to verify the trim length where my brass is just a few thousandths short of the transition to minimize how much carbon can build up there.I had 22cal bushing, but it was for neck turned brass so it necked down too far (oversized), so there was massive neck tension when seating...and the FL bushing die wasn't quite able to reach/size all the way down to bottom of neck. Nevertheless, neck thickness went from .013 to nearly .014 according to my ball micrometer. But once seated with bullet, overall neck diameter was only .250 on the button. I think I'll just go with .253 neck and call it good.

Oh yeah, overall length of this piece of brass grew from 2.563 to 2.573. So I'll probably increase neck length by .020 or .025 over SAAMI, and then depending how how long chamber gets cut, I may or may not have to trim once up front. I might trim and anneal anyhow, since this brass has about 10 firings already.

Below is current 6BR with the 22BR in middle.

Similar threads

- Replies

- 27

- Views

- 3,822

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.