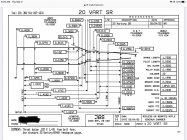

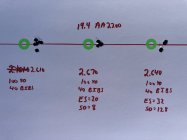

I’ve just started making up dummy rounds to find my Jam length in a new 20 VT build. The reamer was spec’d to have a 0.010 freebore. I set the bullets long and kept using trial and error chambering the dummy rounds until I had no resistance closing the bolt. Then I loaded another dummy round .020 longer, chambered the round and let the chamber seat the bullet to find the Jam length. So I feel very confident that these seating depths as shown in the pictures are at the Jam length. I even loaded +.005 longer than this jam length and got a 0.005 bullet setback when chambering. And loaded -0.002 less than the Jam length and got no resistance or set back.

So what I’m finding is the bullets have to be loaded much longer than I expected in order to reach the Jam. Has anyone ran across this with their 20 VT? With the 40 grain Bibs, I’ll have to have a 0.100 jump in order to get 0.120 of the bearing surface in the neck. I’m not as worried about the 40 vmax, but even it only has about 0.1035 bearing surface in the neck loaded to Jam.

Thoughts?

So what I’m finding is the bullets have to be loaded much longer than I expected in order to reach the Jam. Has anyone ran across this with their 20 VT? With the 40 grain Bibs, I’ll have to have a 0.100 jump in order to get 0.120 of the bearing surface in the neck. I’m not as worried about the 40 vmax, but even it only has about 0.1035 bearing surface in the neck loaded to Jam.

Thoughts?