Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

20 practical reloading help

- Thread starter Vash1322

- Start date

L.Sherm

Silver $$ Contributor

Thats your interpretation, others can take it differently its exactly why I try not to post loads on open forums. Case volume matters. Here's an example im talking about on 2 different 20 Pracs my load is .4 gr different from one to the next using same powder, primer, case and bullet going literally same FPS.I don't think I said anything about substituting loads, I was merely pointing out how well my load shoots in my rifle. The difference in the cases is minimal, the difference is the angle on the shoulder. Everything else is the same.

I'm not trying to jump on your a$$ but be careful shoulder angles change it to a different cartridge and load its why its called a tactical and not practical.

After all the thread is called 20 Practical loading help.

That's your interpretation. If you go back to post #1 you will see that he actually wanted to know what happened to his groups. He was talking about switching powders to Varget. He wondered if temperature could be a problem, I qualified my answer by saying the cartridge and rifle I shoot and then the powder I used. Not once did I recommend he use my load. I linked to show the consistency of the groups I get using TAC.Thats your interpretation, others can take it differently its exactly why I try not to post loads on open forums. Case volume matters. Here's an example im talking about on 2 different 20 Pracs my load is .4 gr different from one to the next using same powder, primer, case and bullet going literally same FPS.

I'm not trying to jump on your a$$ but be careful shoulder angles change it to a different cartridge and load its why its called a tactical and not practical.

After all the thread is called 20 Practical loading help.

What I object to is your trying to big league me. Discredit me. You are the problem with these venues, looking for straw man issues to elevate yourself.

Coyotefurharvester

Silver $$ Contributor

A suppressor SLIGHTLY loose will destroy groups.

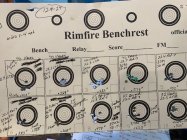

I suggest trying some different bullets and powders. I have done a LOT of load development for several .20 Practical rifles and I have had best luck with Accurate LT32, Reloader7, H4198. The bullets I like to try out are 32 and 40 V-Max, 35 Berger and 39 Blitz king. One or more have always worked with one of the listed powders. You can get really good accuracy with the slower powders, but the accuracy window is often quite narrow. I usually go straight to 32 or 40 V-Max (because they are cheap and almost always shoot great), then to the others. I have attached a photo of a target I shot last week for a new barrel (Hart 1-12" twist, 26") in one of my A/R's. Most of my tubes really like LT32 above all else - this one is definitely liking Reloader 7. When I can get a load to shoot in my varmint rifles at about 1/4" MOA, I usually stop. With that .208" group (group #7) - looks like I'm possibly there on this one. Please forgive all my scribbling - as I was starting to write data for a different rifle that I was doing load development on the same day. I was using previously fired lake City Brass, Tula .223 Magnum primers (though Rem 7 1/2 and Federal A/R Match work equally as well for most loads). I load to maximum magazine length. The lengths I show were using the Hornady tool - they are not actual OAL lengths. I'd not be concerned with "shotgun" groups. Each of my .20 Practicals has thrown out plenty of 1 1/2" groups with powders it doesn't like. I noticed that when I went to the faster powders - those big groups became far less common. Good luck!

Attachments

Last edited:

See if I can send a better picture of that...

Also, I try to find a powder that will shoot tiny groups across a full grain of powder because I shoot my rifles in 32 degree weather and 100 degree weather. I go in the middle to keep my groups from falling apart in the cold weather and to not get too much pressure on the hot days... Targets #7 and #8 were shot with the 35 Bergers. An additional 3/10 grain of powder on #8 saw the group fall apart, along with higher SD's. That is not good - so I'll try reducing the load a bit and re-ladder it. No doubt, a bit of wind came into play and no wind flags out. We'll see if it has potential across that 1-grain spread.

Also, I try to find a powder that will shoot tiny groups across a full grain of powder because I shoot my rifles in 32 degree weather and 100 degree weather. I go in the middle to keep my groups from falling apart in the cold weather and to not get too much pressure on the hot days... Targets #7 and #8 were shot with the 35 Bergers. An additional 3/10 grain of powder on #8 saw the group fall apart, along with higher SD's. That is not good - so I'll try reducing the load a bit and re-ladder it. No doubt, a bit of wind came into play and no wind flags out. We'll see if it has potential across that 1-grain spread.

Attachments

Last edited:

I want to start this out as WOW! When I wrote this I never expected the responses I received! THANKYOU ALL! I will try a few of the suggestions. But first i will answer a few questions:

.

.

- My twist rate is 1-10 inch twist.

- My rifle is a BCM upper with smoke composites hand guard and a WOA gas-block.

- scope is a Leupold VX5 2-10

- I will be shooting this in a WIDE variety of temps ranging from 0F to 90F....

Your max overall length doesn't have to be measured. Your loaded round has to fit in the magazine. That will determine your overall length.I want to start this out as WOW! When I wrote this I never expected the responses I received! THANKYOU ALL! I will try a few of the suggestions. But first i will answer a few questions:

I just attempted to measure my MAX coal for this barrel and hopefully it worked. I will find a group that is close with probably 8208 since that is what I have then try seating depths in increments in .003. I will report back my findings as this has turned very interesting for me. Only problem is it was -15F today and I will wait til it warms up a little

- My twist rate is 1-10 inch twist.

- My rifle is a BCM upper with smoke composites hand guard and a WOA gas-block.

- scope is a Leupold VX5 2-10

- I will be shooting this in a WIDE variety of temps ranging from 0F to 90F....

.

Coyotefurharvester

Silver $$ Contributor

With my 20p AR if I load near magazine length some bullets are just touching lands, not good for semi's. Also with my setup, if I use 0.002 neck tension, I see a slight shorting of the round when round comes off the magazine with full spring. So I check the cbto length if I try a new bullet. I had Lee make a custom taper crimp die, slight crimp and no more bullet movement. This is an issue hunting as the round gets unchambered and put back in the mag for next stop.

As a rule, most chambers are best suited to running your loaded cartridge length to maximum magazine length. As coyoteharvester noted, his rifle will put the bullet at jam, not a good thing as he noted. You can make up a dummy cartridge with no powder or primer and pull the charging handle back and release it, allowing a round to get stripped off the magazine and slammed into the chamber. Extract the round and re-measure length to see if the depth changed. If it did, you are either putting the bullet into jam in the chamber (so need to seat bullet a bit deeper) or you don't have enough neck tension if using bushing dies. Since you will be shooting in a wide range of temperatures (as I do), do try to settle on a load that will shoot accurately across a full grain of powder. Reloader 7 will swing quite a bit with the temp changes, whereas 8208 and LT342 not so much. If you don't get great groups with that 8208, I'd not spend more than 35 or 40 rounds trying to get it to shoot. If you work up your ladder and everything is 3/4" or more, I'd switch to another powder for comparison. Accurate LT32 is my first "go-to" powder when trying out a new .20P. Best luck "usually" comes from the powders faster than 8208. Being unlike bolt guns where you can widely mess with seating depth, you don't have that degree of flexibility with the A/R, so changing powders is usually the best call. A well-matched 20P powder will usually shoot more than one bullet weight and brand better than the others. Good luck!I want to start this out as WOW! When I wrote this I never expected the responses I received! THANKYOU ALL! I will try a few of the suggestions. But first i will answer a few questions:

I just attempted to measure my MAX coal for this barrel and hopefully it worked. I will find a group that is close with probably 8208 since that is what I have then try seating depths in increments in .003. I will report back my findings as this has turned very interesting for me. Only problem is it was -15F today and I will wait til it warms up a little

- My twist rate is 1-10 inch twist.

- My rifle is a BCM upper with smoke composites hand guard and a WOA gas-block.

- scope is a Leupold VX5 2-10

- I will be shooting this in a WIDE variety of temps ranging from 0F to 90F....

.

Last edited:

Hey do you have an adjustable gas block on your rifle. I suggest getting one.

And personally from your targets it looks like your rifle wants to shoot..tune your load

My 20 practical alway seemed to shoot hot and loud no matter what i did an adjustable gas block can help calm down the entire rifle. My recoil buffer was slamming hard in the buffer tube and the adjustable gas block really help tune things in..

Once the rifle is running good then mess with load development..

Just a thought..

And personally from your targets it looks like your rifle wants to shoot..tune your load

My 20 practical alway seemed to shoot hot and loud no matter what i did an adjustable gas block can help calm down the entire rifle. My recoil buffer was slamming hard in the buffer tube and the adjustable gas block really help tune things in..

Once the rifle is running good then mess with load development..

Just a thought..

Similar threads

- Replies

- 46

- Views

- 1,510

- Replies

- 28

- Views

- 1,656

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.