600-60x

Silver $$ Contributor

Picked up a stollie panda in 6 ppc 262 neck i tuun all my match rifle necks but to .13

For this rifle I have no choice but to turn to.8+

Way to thin in my opinion

next years barrel will be .269 neck

But I will say this barrel shoots

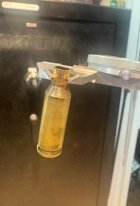

I’m about 10 reloads on the brass and I m getting a bright ring around the necks half way up also has some bullets get loose on a few loaded rounds ?

Nothing wrong with the die setup

I have seen this on the body which means time to toss them before they separate

Is this the same but on the necks?

For this rifle I have no choice but to turn to.8+

Way to thin in my opinion

next years barrel will be .269 neck

But I will say this barrel shoots

I’m about 10 reloads on the brass and I m getting a bright ring around the necks half way up also has some bullets get loose on a few loaded rounds ?

Nothing wrong with the die setup

I have seen this on the body which means time to toss them before they separate

Is this the same but on the necks?