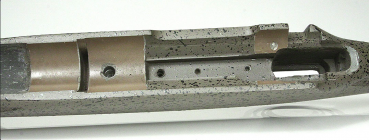

Check your front action screw to make sure it isn’t hitting the barrel threads.

The action is very thin where the front action screw, screws in .It can only screw in one or two threads before it hits the barrel. Some gunsmiths mill relief cut to allow the action screw to catch 3 or 4 threads.

If the screw is hitting the barrel you can see rub marks on the end of the screws first or on top of the threads, when looking down in the hole.

Usually those XP 100s are shooting machines.

Check your bedding by putting your finger at the end of the stock. where the bottom of the barrel and forend meet. Lightly tighten and loosen the screw, one at a time. Have the rifle standing vertical.

If the bedding is good you shouldn’t feel the barrel move.

If you feel much movement your bending the action when the screws are tight.

Hal

The action is very thin where the front action screw, screws in .It can only screw in one or two threads before it hits the barrel. Some gunsmiths mill relief cut to allow the action screw to catch 3 or 4 threads.

If the screw is hitting the barrel you can see rub marks on the end of the screws first or on top of the threads, when looking down in the hole.

Usually those XP 100s are shooting machines.

Check your bedding by putting your finger at the end of the stock. where the bottom of the barrel and forend meet. Lightly tighten and loosen the screw, one at a time. Have the rifle standing vertical.

If the bedding is good you shouldn’t feel the barrel move.

If you feel much movement your bending the action when the screws are tight.

Hal

Last edited: