You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Reducing ES on 10 shot groups

- Thread starter Jerry Snyder

- Start date

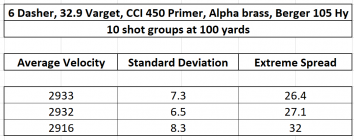

How about, weighing your brass and setting aside the outliers for sighters or 1st shot fouling and maybe also keeping have batches of those brass verily close to the same weight???I dusted off the 6 Dasher yesterday and used my Garmin chrono to log some info. I was happy with the group sizes, about .5 MOA. The velocity were what I expected, also the SD's. The ES were a little high for the group size/SD numbers. What would you suggest to reduce the ES numbers? View attachment 1653371

You can also improve your SD's by weighing primers and culling the outliers.

noahburleson1

Gold $$ Contributor

Try standard primers (non magnum)I dusted off the 6 Dasher yesterday and used my Garmin chrono to log some info. I was happy with the group sizes, about .5 MOA. The velocity were what I expected, also the SD's. The ES were a little high for the group size/SD numbers. What would you suggest to reduce the ES numbers?

Try different seating depth and bullet tension. If that doesn't improve ES try a different powder or a different powder charge. As mentioned before sort brass by weight, bullets by ogive, and assure all primers are seated to same depth.

Dry tumble only, I use a Wilson Micro seater/chamber die. I changed the seating depth by10 thou closer to the lands per advice from a well known shooter on here. ThanksNot wet tumbling are you? What did you do for seating depth? How forgiving was your original load?

Clancy

Silver $$ Contributor

I’d do a full seating test before I went any farther. It’s definitely the most important.Dry tumble only, I use a Wilson Micro seater/chamber die. I changed the seating depth by10 thou closer to the lands per advice from a well known shooter on here. Thanks

10 thou closer to the lands is a pretty aggressive change. Try moving 3 thou at a time. You can easily skip right over a node moving 10 thou at a time.Dry tumble only, I use a Wilson Micro seater/chamber die. I changed the seating depth by10 thou closer to the lands per advice from a well known shooter on here. Thanks

L.Sherm

Silver $$ Contributor

100%10 thou closer to the lands is a pretty aggressive change. Try moving 3 thou at a time. You can easily skip right over a node moving 10 thou at a time.

Shoot strings of 25 to 50 so your 10 shots numbers seem tiny!

R.Morehouse

Gold $$ Contributor

Leave the carbon in the necks, just run a nylon brush straight in and out the same amount of strokes ( before sizing ), be anal about your COAL.......Lots of good suggestions here.....Good Luck

Regards

Rick

Regards

Rick

Yeah.....I covet the brass on it's forth firing. I do not tumble. I justLeave the carbon in the necks, just run a nylon brush straight in and out the same amount of strokes ( before sizing ), be anal about your COAL.......Lots of good suggestions here.....Good Luck

Regards

Rick

wipe off the brass as it comes from the chamber to get the soot

off the necks. and like Rick mentioned, I use a nylon brush to just

go in and out. Nothing aggressive.....Note when seating your bullets,

If one feels it seated on the hard or soft side, set those aside for

foulers or initial sighters......I'll also like to ask if your annealing ??

If not, add that to your to do list.

Side thought.....Did you do the initial primer pocket uniforming on

the new brass ?? Only need to do it once, then done.

L.Sherm

Silver $$ Contributor

Once I started doing this I could "feel" the seating alot more consistent.Leave the carbon in the necks, just run a nylon brush straight in and out the same amount of strokes ( before sizing ), be anal about your COAL.......Lots of good suggestions here.....Good Luck

Regards

Rick

ThisI’d shoot it at distance and if the groups hold up don’t worry about it.

Yes, using an AMP Annealer, will look into primer pocket uniforming.Yeah.....I covet the brass on it's forth firing. I do not tumble. I just

wipe off the brass as it comes from the chamber to get the soot

off the necks. and like Rick mentioned, I use a nylon brush to just

go in and out. Nothing aggressive.....Note when seating your bullets,

If one feels it seated on the hard or soft side, set those aside for

foulers or initial sighters......I'll also like to ask if your annealing ??

If not, add that to your to do list.

Side thought.....Did you do the initial primer pocket uniforming on

the new brass ?? Only need to do it once, then done.

I will try a few 5 shot groups with a one tenth grain, two tenth grain and 3 tenth grain increases this week.Dashers like pressure, you might consider pushing it a little harder and see if a higher node does better.

Similar threads

- Replies

- 62

- Views

- 5,605

- Replies

- 20

- Views

- 3,154

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.