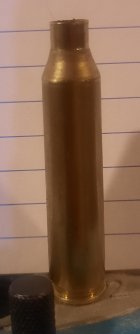

I'm starting to play around with some scrap 223/5.56 brass to figure out exactly what process I want to use to form my 20 practical brass. My upper should be done at the end of the month (can't wait!).

Here's what I KNOW I'm going to do. Start with an RCBS 223 SB die, then my Redding S die with a .235 bushing, then the Redding S die with a .225 bushing and .204 expander. Once I have loaded ammo, I MAY buy a bushing that gives me my desired OD, but for now I'm undersizing slightly and then using the 204 expander to get the final ID. I'll be doing most, or maybe all of this on my Dillon 650. The goal is to run it through the press no more than twice. First pass will be the RCBS die and Redding with the .235 bushing. Second will be the Redding only with the .225 bushing and .204 expander. 2nd pass, I plan on seating primers.

My questions -

First, when should I de-prime? I can't find a 20 or 17 cal stem or sizing button for my RCBS die so de-priming on the first trip through the 650 doesn't seem like it would be an option. Seems like I should be fine de-priming on the last pass since the Redding die will have the 204 expander installed. No reason I couldn't also have the de-capping pin installed. The next station on the 650 can then seat the new primer and it will be ready to load. Does that seem like an acceptable sequence?

Second, while playing around with some scrap range brass, I noticed that after going through the .235 and .225 bushing, the junction between the neck and shoulder doesn't look quite right. It's like the new portion of the shoulder is at a slightly different angle. It almost looks like I didn't run the die down far enough. I can see where the case head has been sized so I'm pretty sure the press allowed me to run the brass all the way into the die body. This kind of makes sense because that portion of the brass is unsupported in the 223 die body. My concern is that this could cause an issue with brass being able to fully chamber. Seems like this could be an even bigger problem on an AR upper. At least with a bolt gun, it would be obvious that I couldn't close the bolt. I don't have my upper yet, so I don't have a good way to check and see if this is an actual issue. Has anyone seen this before? .

I haven't pulled the 204 button through anything yet, so maybe that will "fix" things. I'll try to take a few pics of some brass tonight (ran out of time this morning).

Thanks,

Mark

Here's what I KNOW I'm going to do. Start with an RCBS 223 SB die, then my Redding S die with a .235 bushing, then the Redding S die with a .225 bushing and .204 expander. Once I have loaded ammo, I MAY buy a bushing that gives me my desired OD, but for now I'm undersizing slightly and then using the 204 expander to get the final ID. I'll be doing most, or maybe all of this on my Dillon 650. The goal is to run it through the press no more than twice. First pass will be the RCBS die and Redding with the .235 bushing. Second will be the Redding only with the .225 bushing and .204 expander. 2nd pass, I plan on seating primers.

My questions -

First, when should I de-prime? I can't find a 20 or 17 cal stem or sizing button for my RCBS die so de-priming on the first trip through the 650 doesn't seem like it would be an option. Seems like I should be fine de-priming on the last pass since the Redding die will have the 204 expander installed. No reason I couldn't also have the de-capping pin installed. The next station on the 650 can then seat the new primer and it will be ready to load. Does that seem like an acceptable sequence?

Second, while playing around with some scrap range brass, I noticed that after going through the .235 and .225 bushing, the junction between the neck and shoulder doesn't look quite right. It's like the new portion of the shoulder is at a slightly different angle. It almost looks like I didn't run the die down far enough. I can see where the case head has been sized so I'm pretty sure the press allowed me to run the brass all the way into the die body. This kind of makes sense because that portion of the brass is unsupported in the 223 die body. My concern is that this could cause an issue with brass being able to fully chamber. Seems like this could be an even bigger problem on an AR upper. At least with a bolt gun, it would be obvious that I couldn't close the bolt. I don't have my upper yet, so I don't have a good way to check and see if this is an actual issue. Has anyone seen this before? .

I haven't pulled the 204 button through anything yet, so maybe that will "fix" things. I'll try to take a few pics of some brass tonight (ran out of time this morning).

Thanks,

Mark