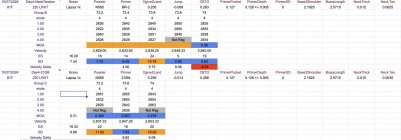

I tested 3 different configurations today for my 300 PRC.

- Barrel is 30" and has bout 200 rounds before the tests.

- Lapua brass, 1x fired, annealed (Annie), trimmed, chamfered, deburred.

- Brass is cleaned by an Ultrasonic Cleaner and neck is lubed with NeoLube2.

- Powder is N565, measured by FX-120i.

- Primers are seated with K&M seating tool (with Gauge).

- All bullets are seated at jam. Berger 220 LRHT.

Group A's (in photo)

- ES/SD and groups are not good so please ignore

Group B's (in photo)

- Primers BR-2

- Neck turned down to 0.012"

- Neck tension 0.0025"

- Decent ES/SD but does not group well.

- The groups were much tighter when the neck tension was 0.0035" and neck was not turned. But ES/SD were higher as well (with virgin brass).

Group C's (in photo)

- Primers 210M

- Neck has not been turned

- Neck tension 0.0035"

- Higher ES/SD but appears to group well

Do you think I can pick a charge in B and adjust seating depth to get it to group like C? Or should I try to get ES/SD down with C?

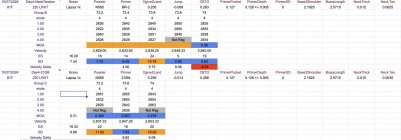

- Barrel is 30" and has bout 200 rounds before the tests.

- Lapua brass, 1x fired, annealed (Annie), trimmed, chamfered, deburred.

- Brass is cleaned by an Ultrasonic Cleaner and neck is lubed with NeoLube2.

- Powder is N565, measured by FX-120i.

- Primers are seated with K&M seating tool (with Gauge).

- All bullets are seated at jam. Berger 220 LRHT.

Group A's (in photo)

- ES/SD and groups are not good so please ignore

Group B's (in photo)

- Primers BR-2

- Neck turned down to 0.012"

- Neck tension 0.0025"

- Decent ES/SD but does not group well.

- The groups were much tighter when the neck tension was 0.0035" and neck was not turned. But ES/SD were higher as well (with virgin brass).

Group C's (in photo)

- Primers 210M

- Neck has not been turned

- Neck tension 0.0035"

- Higher ES/SD but appears to group well

Do you think I can pick a charge in B and adjust seating depth to get it to group like C? Or should I try to get ES/SD down with C?

Attachments

Last edited: