Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

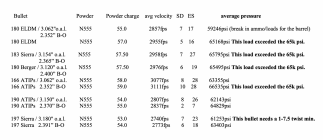

7/6.5PRC Pressure and Velocity ammo test

- Thread starter FrankG

- Start date

G7BC

Gold $$ Contributor

Interesting and not far off from what I was expecting based on all of the conversations about velocities and pressure signs...I'm going to assume with the same powder charges the pressures would be a bit higher with the thicker adg or Lapua brass vs. the Hornady brass used in testing. For what it's worth, with H4350, about 2 grains less powder gave me the same velocities and N555.

In my opinion it's not just if the brass is heavier or thicker if you will. It's the actual case volume that probably makes the biggest difference. The extractor cut can be different dimensionally and that will effect the weight of the brass but it doesn't effect case volume.View attachment 1564565

Interesting and not far off from what I was expecting based on all of the conversations about velocities and pressure signs...I'm going to assume with the same powder charges the pressures would be a bit higher with the thicker adg or Lapua brass vs. the Hornady brass used in testing. For what it's worth, with H4350, about 2 grains less powder gave me the same velocities and N555.

It's also hard to compare brass from Hornady or Lapua or ADG etc... as well as I've seen brass from the same maker vary in weight and volume.

So it goes back to whenever you make a change in components and or a change in a different lot of a given component even from the same maker... that's why they say you should back off your load and work your way back up again.

It will be interesting when I get the data for H4350 and H4831sc and the RL16 loads as well.

Looking at all the loads tested with the N555 powder and seeing how consistent the SD's and ES numbers are that was pretty impressive with all of those different bullets.

FeMan

Gold $$ Contributor

I found when I measured some 300 PRC brass that the Lapua was heavier then the Hornady AND the Lapua had a higher internal capacity. Water capacity was 95.4 for Hornady and 96.9 for Lapua, and the Lapua case was 8 grains heavier. That is counter intuitive and not what I expected. I guess the Lapua brass has a higher density?

I updated my original post with more data. So click on the attachment and it is currently up to date.

I'm still waiting on one load with the 190ATIPs and H4831sc as well as the loads with RL16.

When all the testing is completed they will take some of the original rounds they used for baseline and barrel break in... and rerun some of that ammo. That will tell us if and how much if it did...the barrel speed up and give us a pressure correction etc...The barrel is currently from what I'm seeing have 200 or so rounds on it.

Later, Frank

Bartlein Barrels

I'm still waiting on one load with the 190ATIPs and H4831sc as well as the loads with RL16.

When all the testing is completed they will take some of the original rounds they used for baseline and barrel break in... and rerun some of that ammo. That will tell us if and how much if it did...the barrel speed up and give us a pressure correction etc...The barrel is currently from what I'm seeing have 200 or so rounds on it.

Later, Frank

Bartlein Barrels

No… why?did or will anybody try to determine internal capacity of the brass before and after firing? ballpark , i know its hard to get exact

I could take a virgin case and do a water capacity from it and I can ask Hornady to send me one back that was shot and do that as well. Then you would have a before and after assessment on that and see how much it changed.

I guess my question is… what do you think it’s going to tell you? If you think that comparing that to another case that has slightly more or slightly less capacity will give you an indicator of you being able to run more or less powder… I think your looking for wrong data.

Also what your reamer cut the chamber to vs what the test barrel got cut to… if your brass is expanding more or less than the chamber of the test barrel as well as the variance of the brass lot it will effect the numbers.

How do you factor in powder in a given production lot can have a +/- 3% burn rate variance for example… how do you factor that in?

To get any good data I think you will have to take a case with X amount of water capacity and take another case or brand if you will with X amount of water capacity and load them with the same lot of powder and same powder charge etc… and see what it does for velocity and how if it does effect the pressure. Otherwise your data will be skewed.

Assuming I have the same lot of the brass that’s been fired in my gun…. as it has the same chamber reamer in my barrel as the test barrel. I’m pretty sure it’s the same lot but not a 100% positive.Just looking a general idea of case capacity

Virgin brass which I know is the brass I loaded for the test in the pressure barrel…

67.7 for virgin brass

The fired cases out of my gun is 67.8.

That’s for water capacity.

I’ll ask my counterpart at Hornady that is running the test to check the fired cases he has and see what he comes up with.

Later, Frank

I didn’t mean to come across harsh. I apologize if I did.Just looking a general idea of case capacity

I had to ask the question though as to where it was going.

There are just a ton of variables in this stuff. That’s all.

noahburleson1

Gold $$ Contributor

Dang your barrel is even faster than mine haha. I thought mine was fast at 2940 with 56.3gr n555My barrel sped up right around the 350 round mark. Give or take. Getting an average of 2970fps with the 180 hybrids and 56.2gn’s of triple nickel.

Sandstorm

Gold $$ Contributor

Im thinkin its going to catch up with you eventually. Ive pushed them hard before as well.Getting an average of 2970fps with the 180 hybrids and 56.2gn’s of triple nickel.

Its just not worth the headache ..at least for me.

Barrels are expendable and I have a reamer.Im thinkin its going to catch up with you eventually. Ive pushed them hard before as well.

It’s just not worth the headache ..at least for me.

There are guys I know running 57.1gn.

So it should go without saying but I will say it anyways. Lot of powder variances, bullet lot variances from lot to lot and not to mention bullet diameters, primers, brass lot etc... all can change the pressure and velocities. Be careful with what you do! Don't forget.... temperature, humidity, pressure, altitude etc... can have an affect as well. This test was run in a lab in controlled conditions.

Not to mention that differences in chamber reamer spec's of what we used for the test/in our guns here and the pressure test barrel vs what you might have in your gun and as well as what your barrel measures for bore and groove dimensions vs what our test barrel was made to can make a difference as well.

Again I have to give a big thanks to Hornady and Joe and Jayden there for supplying the brass, bullets (166 and 190 ATIPS) and running the test! Thanks to Tommy at Sierra for supplying the 183SMK and 197SMK bullets for the test. Thanks to Ken at Capstone for supplying the Berger 180 Hybrids and the N555 powder used in the testing. The guys here at Bartlein for making the barrel and for Scotty here doing the chamber work and pressure port work etc.. in finishing the test barrel.

Max working pressure for the round is 65,000psi.

Twist does not effect pressure.

All pressure and velocity data is for 10 rounds fired for each load.

The p&v barrel measured 32" finish length.

Twist = 1-8.25

5R rifling

Bore size = .2773"

Groove size = .2843"

Headspace = go +.0002"

All of the ammo listed below has N555 powder. All ammo loaded with CCI#200 Primers. All brass was Hornady brass. All primer flash holes where checked for and or deburred.

All bullets where seated .020" off the lands of a brand new chamber. This was not a bullet test for accuracy. So no bullets/ammo had the bullets seated closer to the lands or further off the lands. No load tuning was done in anyway shape or form. In making this statement no bullet clearly out performed one over the other. All bullets shot very good. Noticed I listed the o.a.l. of my loaded rounds and not the base to ogive dimension. Some of my o.a.l. data I left at home. Let me update that information later today.

So for the 180gr class bullets.... I will say as you approach the 57.0gr powder charge... approach it with caution as you are going to be hitting that 65psi limit even possibly before depending on all the variables. There where no flat primer signs, hard extraction etc... At the top I put in bold letters... average pressure that's because that's the average. There are rounds fired with in a group that could be over the number listed for velocity and pressure was even slightly higher... so these numbers are an average. A good example is the 55.0 load for the 190ATIP. The average is 64829 but there where 3 rounds that went just past the 65k limit.

I'm still reviewing numbers and data and with more data to come for H4831sc, RL16 and H1000 powders. So check this post from time to time as I will be making updates as more information comes in and I'll try and keep my original post #1 going as I get more info.

I was having trouble with the layout on the post. So I saved it as a pdf. You have to click on the attachment. I'll clean it up more later.

Later, Frank

Bartlein Barrels

P.S. it should go without saying but I will say this... "Guys keep your comments civil and think before you type!" Everyone involved with getting this testing done did not receive any $ compensation in anyway shape or form. Everyone did this as a request/thought from me and we all did it to help the shooting community using this round and that there is no baseline/data for to go off of. I don't even want to know how much time and set up it took Hornady to run the test and compile the data and the cost involved with that.

Are the pressure readings here for this specific powder charge and this specific FPS?

For example, what if I need a higher charge to get the same velocity due to the powder being store in a more humid location?

Would the higher charge and the same velocity end up with more PSI?

Last edited:

Sandstorm

Gold $$ Contributor

Mee too..but your missing the point however.Barrels are expendable and I have a reamer.

You implying a blown up rifle? I’m not seeing any pressure signs in my rig with this load.Mee too..but your missing the point however.

Similar threads

- Replies

- 2

- Views

- 2,360

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.