I did mine on a sunnen pin hone.How are you honing them? I'm very mechanical. I do have a drill press. I do not have a lathe.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Honing the Neck in Sizing Die

- Thread starter Turpentine

- Start date

The one thing you don't want is a FL Die that sizes the neck way down so that whatever means you use to expand back to something near your target diameter works the crap out of the brass.

How many don't even know/measure what you dies are doing to your brass?

Use bushings, hone, whatever brand of die, you don't want to work the neck down several thou then back up each time you size.

I have a few different FL dies in the 22 cal calibers that work the necks down but like the Redding Body die that doesn't touch the neck. Then stick something in the neck, mandrel, pin, ball, to finalize neck I.D.

I like the Lee Collet Die and seem to get nice repeatable neck tension.

Neck I.D., bullet diameter less your desired 'Neck Tension', seems to be the dimension most are after.

You can approach that from the inside or the outside.

Relying on neck O.D. and your neck thickness to give you a correct I.D. requires extremely consistent neck thickness.

Occasionally I need to use a small base die for my AR (22 Nolser). I used a 0.248" Carbide Reamer then some fine paper 2000 grit to soften the leading edge of the neck area and polish the inside.

I don't neck turn and variations in neck thickness prevents getting good results from final sizing from the outside.

How many don't even know/measure what you dies are doing to your brass?

Use bushings, hone, whatever brand of die, you don't want to work the neck down several thou then back up each time you size.

I have a few different FL dies in the 22 cal calibers that work the necks down but like the Redding Body die that doesn't touch the neck. Then stick something in the neck, mandrel, pin, ball, to finalize neck I.D.

I like the Lee Collet Die and seem to get nice repeatable neck tension.

Neck I.D., bullet diameter less your desired 'Neck Tension', seems to be the dimension most are after.

You can approach that from the inside or the outside.

Relying on neck O.D. and your neck thickness to give you a correct I.D. requires extremely consistent neck thickness.

Occasionally I need to use a small base die for my AR (22 Nolser). I used a 0.248" Carbide Reamer then some fine paper 2000 grit to soften the leading edge of the neck area and polish the inside.

I don't neck turn and variations in neck thickness prevents getting good results from final sizing from the outside.

Last edited:

https://www.sunnen.com/Catalog/Honing/Honing-Portable-Hones said to work well on revolver cylinder throats?

I used a sunnen, LLB 1660.https://www.sunnen.com/Catalog/Honing/Honing-Portable-Hones said to work well on revolver cylinder throats?

I do plan to get Lee to make me a slightly smaller mandrel for the custom Collet die they built me. It's just not giving me enough neck tension. I think part of the reason is that I turned some of my necks down too far or may be getting a little too much spring back. Or a combination of the two. I'm paying a lot more attention to that with the Lapua brass I'm using now. My loaded OD is .291. That is with.264 diameter bullets. I'd like to size back to .289 consistently but some of my outside IDs wind up at .290-.2895, possibly a touch more. But I just discovered the issue and with all that's been going on I haven't been able to work through it yet.. I still would like to remove or hone my FL die to somewhere in the .288-.2885 area and reduce the diameter of my expander ball to keep from working the brass so much during initial sizing and conversion to 6.5-05. I actually tried one of my 270 dies with the expander ball removed but it doesn't quite take the necks far down far enough. It would have been great if it had.The one thing you don't want is a FL Die that sizes the neck way down so that whatever means you use to expand back to something near your target diameter works the crap out of the brass.

How many don't even know/measure what you dies are doing to your brass?

Use bushings, hone, whatever brand of die, you don't want to work the neck down several thou then back up each time you size.

I have a few different FL dies in the 22 cal calibers that work the necks down but like the Redding Body die that doesn't touch the neck. Then stick something in the neck, mandrel, pin, ball, to finalize neck I.D.

I like the Lee Collet Die and seem to get nice repeatable neck tension.

Neck I.D., bullet diameter less your desired 'Neck Tension', seems to be the dimension most are after.

You can approach that from the inside or the outside.

Relying on neck O.D. and your neck thickness to give you a correct I.D. requires extremely consistent neck thickness.

Occasionally I need to use a small base die for my AR (22 Nolser). I used a 0.248" Carbide Reamer then some fine paper 2000 grit to soften the leading edge of the neck area and polish the inside.

I don't neck turn and variations in neck thickness prevents getting good results from final sizing from the outside.

Last edited:

I bought a few undersized mandrels for the LCD.

Easy to turn down a thou or two.

Easy to turn down a thou or two.

Took a while but found it!Post the video please.

I know there’s been a lot of details given in the replies here but my answer to the original questions are, and I will readily admit I was a cheapskate here, I used a barrel lap and lapping compound in a lathe to open the neck of my Lee full length resizing die so that the neck of fired brass is .001” smaller than what it measured as fired but not yet sized. (I have 200 Prime cases and 200 Nosler cases and they’re all pretty consistent). For some reason it just seemed to me that resizing the neck just a little would be better for concentricity than not sizing the neck at all. I do not use any expander with the die and push the shoulder about .002”

I don't see why you couldn't carefully use the barrel lap with a drill press.

Next I use a Lee collet die with a lightly polished mandrel to get my neck tension which is about .002". Be careful polishing those Lee mandrels. They must be soft, material goes away real fast.

I don't see why you couldn't carefully use the barrel lap with a drill press.

Next I use a Lee collet die with a lightly polished mandrel to get my neck tension which is about .002". Be careful polishing those Lee mandrels. They must be soft, material goes away real fast.

Last edited:

With a lathe you could easily make a Lee Collet Die mandrel, pin with a small flange, ignoring the decapper pin out of some harder material.

I know you meant Lee Collet Neck Sizing Die instead of the Lee Factory Crimp die.

I know you meant Lee Collet Neck Sizing Die instead of the Lee Factory Crimp die.

All the Lee metals in the new LCD's are literally garbage. Probably made out of chicom recycled mixed stainless. I had one that bled brown rust goo if oiled! I am going to get a handful of collets and anvils and process and then send them in for nitriding.

I dont know anything about machining but how hard would it be to make a collet?

I dont know anything about machining but how hard would it be to make a collet?

I like the nitriding idea.

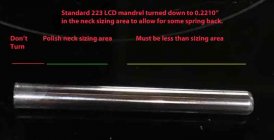

Here's what I did with a standard mandrel.

Had to cut it short for my modified 223 die to size the neck of my 22N cases without bottoming out on the web. I have another one turned down to 0.220", and a couple Lee undersized @ about 0.222".

Hammer peened flange on a 0.221" hard pin would work.

Wait for a free shipping day and get the whole works for $23.

Here's what I did with a standard mandrel.

Had to cut it short for my modified 223 die to size the neck of my 22N cases without bottoming out on the web. I have another one turned down to 0.220", and a couple Lee undersized @ about 0.222".

Hammer peened flange on a 0.221" hard pin would work.

Wait for a free shipping day and get the whole works for $23.

Last edited:

Yes, thanks. I'll go fix the post.I know you meant Lee Collet Neck Sizing Die instead of the Lee Factory Crimp die.

Last edited:

I have used Rick Averill's method to do several dies and I'm very happy with the results. I just use a small rechargeable drill to hold the lap and hold the die in my hand. I think this is a good method as it allows the die to pretty much float, which helps it stay aligned, and you get a lot of feedback in the feel of it. I use lapping compound that I got from Brownell's, best cutting seems to be the 125 grit for some reason. Then I finish it with 2 finer grades. Main thing to learn is to be patient and check your progress frequently. You can overdo it without realizing it.Exactly what I was looking for. I actually have a Lee Collet I can use for a mandrel if need be but I don't get consistent enough results sizing with the collet for some reason.

You guys have been very helpful. I have lapping compound at home. I have a lot of tools. What size lap would I need to lap a 6.5 die to .288-.289?

Pretty sure I used a 9/32" expandable which can be expanded up to 15%, which would be... .323"?

McMasterCarr no. 4548A14 and 4548A54 replacement barrel in case the included one wears out (not likely on just one die).

It's been a couple years ago but if I remember correctly I opened mine up to like .293-.294.

Get a pin gauge for the dimension you want to hit and hone, check, hone, check, hone, check. Then if needed expand the lap just a little bit and repeat. Creep up on it. At least for somebody like me it would be easy to overshoot

McMasterCarr no. 4548A14 and 4548A54 replacement barrel in case the included one wears out (not likely on just one die).

It's been a couple years ago but if I remember correctly I opened mine up to like .293-.294.

Get a pin gauge for the dimension you want to hit and hone, check, hone, check, hone, check. Then if needed expand the lap just a little bit and repeat. Creep up on it. At least for somebody like me it would be easy to overshoot

Last edited:

Thank You Sir! I ordered 220 grit which should cut fairly slow and help me creep up to the proper size. Plus I have lapping compound for scope rings in the shop Just not sure what grit.Pretty sure I used a 9/32" expandable which can be expanded up to 15%, which would be... .323"?

McMasterCarr no. 4548A14 and 4548A54 replacement barrel in case the included one wears out (not likely on just one die).

It's been a couple years ago but if I remember correctly I opened mine up to like .293-.294.

Get a pin gauge for the dimension you want to hit and hone, check, hone, check, hone, check. Then if needed expand the lap just a little bit and repeat. Creep up on it. At least for somebody like me it would be easy to overshoot

Halffull

Silver $$ Contributor

I would like to lap a 223 die to .246-.248. Which of the following lap tools should I purchase from this link?

www.mcmaster.com

www.mcmaster.com

I will likely buy pin gauges for .246..247,.248 and work up until satisfied.

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

I will likely buy pin gauges for .246..247,.248 and work up until satisfied.

I used a .25 lap that I turned down on a lathe, if you dont have a lathe available II would like to lap a 223 die to .246-.248. Which of the following lap tools should I purchase from this link?

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.www.mcmaster.com

I will likely buy pin gauges for .246..247,.248 and work up until satisfied.

would buy the 6mm.

WSnyder

Silver $$ Contributor

1/4”, reduce the size of it a little then lap. Just as recommended above.I would like to lap a 223 die to .246-.248. Which of the following lap tools should I purchase from this link?

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

Edit: The 6mm mentioned above is .23622” so it would have plenty of room to expand to your dimensions.

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

Here’s a website describing the process as mentioned above.

Lapping Reloading Dies

In this project I will take you through the steps and method of altering the neck dimension on a standard reloading die. The purpose of this is to maintain neck alignment to the case body for the b…

Last edited:

Similar threads

- Replies

- 17

- Views

- 3,706

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.