First post. Thanks to all who actively participate on these forums. I've spent the last several months reading hundreds of threads, using the search function, and trying to learn. Absolutely love the community and have greatly benefited as I move from a Dillon 550 loading pistol and mil-spec rifle ammo to precision reloading for target ammo.

I have two rookie questions. Question 1. How important is it to have the dummy round COAL match the actual round?

The listed COAL for 6mmbr is 2.44" and 2.80" for 6x47L. My brother and I are having rifles built for 1:7.5" and 1:12' twist barrels in 6x47L as well as 1:13.5" and 1:10" barrels in 6mmbr.

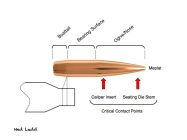

Another member posted a video years ago of the proper way to give your smith dummy rounds where you seat the heel of the bullet to the neck/shoulder junction. After rough measuring (laying the bullet out beside the case) I found my COALs for 6mmbr ranged from 2.03"(Sierra 70 Blitzking) to 2.24" (Nosler 90 Spitzer) using this method. The COALs of the 6x47L varied from 2.36"(Barts 68 Ultra/Berger Column) to 2.61"(Sierra 107 Matchking/105 Scenar).

I understand that free bore comes into play here and am requesting 0 to 0.045 FB for the 13.5" 6mmbr as it will be for 60-70 grain bullets, a 0.060-0.080" FB for 1:12 and 1:10 twists for both 6mmbr and 6x47L in 65-90 grain bullets. Finally 0.105-0.120 FB for 6x47L with 80-107 grain bullets. All free bores are based on the most recommended option/range from previous threads.

Should I be concerned in the COAL variation between bullet types and a consistently shorter COAL than what manuals lists? The Sierra manual does adjust the COAL to the bullet and is very close to what I measured.

question 2. Is the % fill of powder listed in some bullet manuals based on a bullet heel to shoulder/neck junction seating? Does it stop at the neck/shoulder without considering bullet heel or base location?

Thank you.

I have two rookie questions. Question 1. How important is it to have the dummy round COAL match the actual round?

The listed COAL for 6mmbr is 2.44" and 2.80" for 6x47L. My brother and I are having rifles built for 1:7.5" and 1:12' twist barrels in 6x47L as well as 1:13.5" and 1:10" barrels in 6mmbr.

Another member posted a video years ago of the proper way to give your smith dummy rounds where you seat the heel of the bullet to the neck/shoulder junction. After rough measuring (laying the bullet out beside the case) I found my COALs for 6mmbr ranged from 2.03"(Sierra 70 Blitzking) to 2.24" (Nosler 90 Spitzer) using this method. The COALs of the 6x47L varied from 2.36"(Barts 68 Ultra/Berger Column) to 2.61"(Sierra 107 Matchking/105 Scenar).

I understand that free bore comes into play here and am requesting 0 to 0.045 FB for the 13.5" 6mmbr as it will be for 60-70 grain bullets, a 0.060-0.080" FB for 1:12 and 1:10 twists for both 6mmbr and 6x47L in 65-90 grain bullets. Finally 0.105-0.120 FB for 6x47L with 80-107 grain bullets. All free bores are based on the most recommended option/range from previous threads.

Should I be concerned in the COAL variation between bullet types and a consistently shorter COAL than what manuals lists? The Sierra manual does adjust the COAL to the bullet and is very close to what I measured.

question 2. Is the % fill of powder listed in some bullet manuals based on a bullet heel to shoulder/neck junction seating? Does it stop at the neck/shoulder without considering bullet heel or base location?

Thank you.