Did you get yours already. I shipped a ton out yesterday. Had to be out a big part of the day today but was able to get several more ready to go. Let me know what ya think when you use it a bit.That looks great Mike.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Finding the lands...Tool!

- Thread starter gunsandgunsmithing

- Start date

Probably be there in tomorrow's mail, is my guess. Check your spam for tracking on it. It was supposed to send tracking to you, fwiw.I haven’t been to the mailbox today. I’ll check in the AM. Thank you.

Fullbore308

Silver $$ Contributor

Received mine Sir Mike,

TheE-Z CHEK’ R has certainly made this process straight forward. I now have a consistent datum point to start at. I’d just check two barrels that I’d received from GS they are spot on same. Chamber at same time. The test barrel I was testing on seating depth from a cut last year was what I thought touch to .020 off was actually somewhere jamb and .012 off. Certainly a consistent tool other than going by feel or by bolt close W/O fire control. Great job Mike, thanks for your talents sir. Thanks Jeremy Spencer

TheE-Z CHEK’ R has certainly made this process straight forward. I now have a consistent datum point to start at. I’d just check two barrels that I’d received from GS they are spot on same. Chamber at same time. The test barrel I was testing on seating depth from a cut last year was what I thought touch to .020 off was actually somewhere jamb and .012 off. Certainly a consistent tool other than going by feel or by bolt close W/O fire control. Great job Mike, thanks for your talents sir. Thanks Jeremy Spencer

Schippergreg

Silver $$ Contributor

Got mine today. Looks and works great.

X-Caveman

Gold $$ Contributor

Got mine very quickly and decided to use it to help me do something ill advised - move old brass from one chamber to another. A few years ago, Alex set me back a retired long range barrel to 21-1/2” 6BR panda barrel threaded for a suppressor. It’s a hoot to shoot, but I’ve never done much load work for it or shot it in competitions. It’s never even gotten its own fresh brass.

I was out burning thru some old ammo with it a few weeks ago and the range owner talked me into shooting it in our 2023 300yd clay matches held at his range. What the hell, I’ll try it.

I had about 75pcs of brass prepped from the retired barrel. About 20pcs loaded. I did some initial load work with the other 55. Basically looking for pressure and velocity nodes. I could tell the brass was a poor fit to the chamber, but luckily, this short barrel’s chamber is deeper/ looser.

I took my Whidden F/L die and backed it out about .04” so I knew it wouldn’t touch the shoulder. I sized 6 pcs of brass and checked them with a stripped bolt.

The bolt fell closed on 4, and required some pressure on 2. I assume the 2 were fired in this chamber and the 4 in the old one, but I don’t know that as it’s all mixed up.

I removed the barrel and assembled the indicator to the EZ-Ceck.

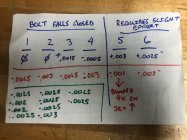

Inserted brass #1 and zeroed it. I did a little gage R&R and the same piece always measured zero! I proceeded to check all 6 pieces. The ones that the bolt fell on were between minus .0005” & +.0015”. The ones requiring a little pressure were +.003” & +.0025”. Thad adds up. I grabbed the +3 and started creeping down on the die until I bumped its shoulder back to .0015”. I removed the die and put a mark on the lock ring and thread, then bumped it a little more.

I was out burning thru some old ammo with it a few weeks ago and the range owner talked me into shooting it in our 2023 300yd clay matches held at his range. What the hell, I’ll try it.

I had about 75pcs of brass prepped from the retired barrel. About 20pcs loaded. I did some initial load work with the other 55. Basically looking for pressure and velocity nodes. I could tell the brass was a poor fit to the chamber, but luckily, this short barrel’s chamber is deeper/ looser.

I took my Whidden F/L die and backed it out about .04” so I knew it wouldn’t touch the shoulder. I sized 6 pcs of brass and checked them with a stripped bolt.

The bolt fell closed on 4, and required some pressure on 2. I assume the 2 were fired in this chamber and the 4 in the old one, but I don’t know that as it’s all mixed up.

I removed the barrel and assembled the indicator to the EZ-Ceck.

Inserted brass #1 and zeroed it. I did a little gage R&R and the same piece always measured zero! I proceeded to check all 6 pieces. The ones that the bolt fell on were between minus .0005” & +.0015”. The ones requiring a little pressure were +.003” & +.0025”. Thad adds up. I grabbed the +3 and started creeping down on the die until I bumped its shoulder back to .0015”. I removed the die and put a mark on the lock ring and thread, then bumped it a little more.

Attachments

X-Caveman

Gold $$ Contributor

Now it read -.001”.

I sized the other 5 at that setting, and they all bumped more! Even though they only had a total of 2 sizing cycles vs the several on the piece I crept down on. Sizes after forming in orange.

Seemed a little too much, so I backed the die off a little more. I tossed the 6 pieces I started with and sized the rest of my brass. The numbers in green are a random sampling of 10 pcs. Only about .001” total variation, but still probably over sizing some. I bet they’ll be a good fit after the next firing.

I’ll use the tool to find touch once I get around to loading these rounds.

So far, so good. Nice to have quantitive data from my own chamber, rather than relying on feel alone or feel & a comparator. A handy gadget, reasonably priced. I’m happy.

I sized the other 5 at that setting, and they all bumped more! Even though they only had a total of 2 sizing cycles vs the several on the piece I crept down on. Sizes after forming in orange.

Seemed a little too much, so I backed the die off a little more. I tossed the 6 pieces I started with and sized the rest of my brass. The numbers in green are a random sampling of 10 pcs. Only about .001” total variation, but still probably over sizing some. I bet they’ll be a good fit after the next firing.

I’ll use the tool to find touch once I get around to loading these rounds.

So far, so good. Nice to have quantitive data from my own chamber, rather than relying on feel alone or feel & a comparator. A handy gadget, reasonably priced. I’m happy.

It's a handy little tool. Glad to hear ya'll like it, too. Thank you!

like it, too. Thank you!

Is it possible to index the tool off the breach face end of the barrel tenon instead of the shoulder end? This way the tool could be used for shouldered as well as barrel nut barrels? I would think it wouldn't matter where the datum is located as long as it's repeatable.Yes, like WSnyder said....it's using your actual chamber so it doesn't get much better than that. It's very accurate and repeatable. Fast and easy. It just requires the bbl be off is the only down side. These are going to work for virtually any bbl with a 1-1/16 tenon so it won't work on the large shank Savages and the few actions out there with larger tenon od's. I could modify a few to work with those but the nut on a Savage makes it tough as the tool indexes off of the bbl shoulder. It'll also work on smaller tenons, like a Winchester or Ruger 1" tenon but it'll obviously be a loose fit over those tenons, but will work.

No, not as is but you guys keep coming up with good ideas. I had thought about Savages etc but didn't give it much thought. I'll have to ponder on it just a little but I think I could either make one for specifically Savages or maybe an insert that can go inside of these. I can't do it right away but check back with me in a few weeks and I'll try to come up with something. It might take just a little more work to have the tool and a spacer/adapter to convert it to do shouldered and unshouldered bbls. Thanks! Check back with me either here or pm in a few weeks.--MikeIs it possible to index the tool off the breach face end of the barrel tenon instead of the shoulder end? This way the tool could be used for shouldered as well as barrel nut barrels? I would think it wouldn't matter where the datum is located as long as it's repeatable.

...getting a bunch/several out there. I think you'll start hearing more feedback on the tool pretty soon. Hard to believe how something so simple can be so versatile and handy.

Dusty Stevens

Shiner

Just screw a nut on a savage barrel and start measuring. Wrap some tape around the nut so it doesnt move

I have not. Had a fair amount of storm damage a couple of weeks ago. Had some damage to my house, a roof torn off of a barn and the wind really worked over another barn too..racked it sideways, busting some internal bracing etc.Hi Mike! I'm just checking in. Have you been able to make any progress on the "Savage" tool?

I'm a week or so behind on orders.

Similar threads

- Replies

- 54

- Views

- 5,626

- Replies

- 9

- Views

- 1,137

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.