As I understand it... a little bit of both.

When the cartridge is fired, the firing pin is going to shove the case forward until it stops (assuming a rimless bottleneck cartridge case like a .223 Rem for the sake of discussion) on the shoulder, then sets off the primer. The powder ignites, builds pressure, and seals the case neck against the chamber walls. There's an ever so slight amount of space now between the bolt face and the cartridge head, and the case body stretches back to it. Not sure if I'm explaining that perfectly, but hopefully you get the gist.

Likewise, when you size the cartridge case, you are squeezing the case into a hole that is smaller than itself (currently). Some of that gets pressed in, but it's more like squeezing a tube of toothpaste: Even when you push the shoulder 'back', some of that material getting displaced is going to basically extrude out the top of the die, via the case neck. As the case has different wall thickness, going from the web, up the body to the shoulder, then through the shoulder to the neck... as that thicker metal in the shoulder gets displaced, it moves into the junction of the neck and shoulder, creating a slightly tighter spot.

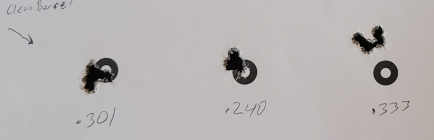

Bushing dies typically don't size quite all the way to the shoulder, so that tight spot maybe lasts a littler longer before it becomes an issue. Either way, it's less than ideal to use your bullet as an expander mandrel to push that donut out of the way (swaging 70/30 cartridge brass using a copper-jacketed lead slug = no bueno). Some sort of expander - ball or mandrel - helps to move that brass to the outside of the case neck, assuming there is adequate clearance in the chamber. Or, if as mentioned above, the bullet is seated so that the body/boat-tail junction stays above (some advocate keeping it 30+ thou above) the case neck/shoulder junction... the bullet will never touch the donut, and it becomes a moot point.