I believe there can be a

lot more to it in some instances, meaning we can't always know every single detail of someone's setup and reloading practices merely from reading terse descriptions at internet shooting forums. This especially concerns me when we're talking about running heavies in .223 Rem loads that are predicted (QL) to be over 60K psi, or thereabouts. The people I know that have successfully run loads like this have spent years testing and define their reloading approach with these loads and it's not something that can be outlined fully in just a few sentences.

For example, it has been well-documented that jacket failures with heavy .224" bullets can be largely mitigated using a

0.219"/0.224" rather than a

0.218"/0.224" bore/groove configuration. My testing leads me to believe that the 0.219" bore also runs markedly lower pressures for a given load, even though velocity for a given charge weight does not seem to change at all. One explanation for this might lie in reducing the amount of pressure derived from the engravement force. In addition, one occasionally hears of using things such as gain-twist barrels and bore rider reamer/chamber designs to help minimize the effects of relatively high-pressure loads. Then there is the varying case head/webbing thickness (and hardness) of different brands of .223 Rem brass that allows some brands to withstand higher pressure than others. Unfortunately, detailed descriptions of such equipment modifications often appear to be overlooked when loads producing almost fantastic velocities are described at internet shooting forums.

My point is simply that reloaders/shooters should exercise caution when considering whether to use a particular .223 Rem rifle setup to launch 85-95 gr bullets. Further, if the decision is made to pursue this path, one needs to exercise extra caution during the load workup due to the pressures that are likely to be involved. I get it, everyone wants that extra little bit of an edge on their competitors, especially when it can be obtained from a cartridge with minimal recoil like the .223 Rem. Nonetheless, a valuable exercise for anyone thinking about going down this road would be to compare the predicted wind deflection for a .224" heavy bullet at velocities corresponding to realistic accuracy nodes.

As an example, the 2850 fps velocity often seen at shooting forums probably originates from the fact that it represents a very good accuracy node with 90 VLDs from a 30" barrel over H4895 (OBT Node 4/1.3684 ms). Unfortunately, running such a load is VERY hard on brass. For that reason, some choose to run the 90s at a slightly more reasonable velocity of around 2775 fps, which is much easier on brass and also shoots with extremely good precision. So what would be the

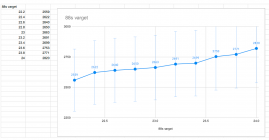

predicted difference in wind deflection for loads with 90 VLDs at 2850 fps versus 2775 fps?

View attachment 1406761 View attachment 1406762

I ran ballistic predictions at JBM Ballistics using a generic set of atmospheric conditions for 90 VLDs at 2850 and 2775 fps. As can be seen in the outputs, the 2850 fps load would enjoy a predicted wind deflection of ~0.1 MOA less than the 2775 fps load at 600 yd, and ~0.3 MOA less at 1000 yd. I'm going to go out on a limb here and state that very few F-TR shooters could actually shoot the difference between these two loads at 600 yd in terms of generating a bona fide statistical difference. A statistical difference in scores might well be realized over time with the predicted 0.3 MOA difference at 1000 yd, but again, it's not an "in your face huge" difference. I understand that it's human nature to strive for every little bit of performance possible, especially among shooters that routinely place at the top of the leaderboard in big matches. Nonetheless, I think the fairly minor differences in wind deflection between running 90 VLDs at these two different nodes illustrates the principle that velocity isn't everything, especially when really poor brass life is part of the equation at the high node. Food for thought.