is the barrel bedded in the fore end to help support that truck axle??

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pre-range load testing, .408

- Thread starter davidjoe

- Start date

This ia proof lawyers make too much money.Then, I really won’t get to use it in F-Class.

Last edited:

I’m confused, so you did try the 416 cal bullets in this with no ill effects?

I’m confused, so you did try the 416 cal bullets in this with no ill effects?

is the barrel bedded in the fore end to help support that truck axle??

Good questions Sigma. I’ll unpack the first one, first. The pictures, loading, shooting and thread post were all concurrent and I was only considering the A-Tips to be heavy for caliber, not “wide” for caliber, until I read Ray’s post. As background, I shoot heavy A-Tips a lot. 250’s in fast twist 300 Win Mags, and even in .308’s, and 190’s in saums and even .284’s.

To directly answer your question, as to pressure, no, but let me qualify that. As an unknown load, I selected powder weights conservatively, and the low/modest primer pressure was not out of line with what I expected, again, assuming I had the correct bullet loaded, but there is nothing to say that the pressure signs shouldn’t have been even lower, either, and my guess was off. I won’t be finding out, I simply surmise that these being a lead core, thin jacketed bullet surely helped to “absorb” the diameter difference.

As JLT and Ray point out, the diameter difference is not .04 mm as the labels would imply, it’s also not zero difference under the thinking that rounding, trade names and nomenclature conventions, or different measuring standards are in play, such that what manufacturers call a “30 Cal” on a box of 100 bullets is a true .3080” and it works in what we call 300 mags and in “308’s,” - rather it is a true .008” difference, here.

So, as to other possible “ill effects” besides pressure, the two bullets were stiff to seat in virgin necks. However, in my .375 CheyTac Peterson brass, Lehigh bullets were also very tight, and indeed I also see this resistance in small mags like ADG’s 7 saum brass with A-Tips and others, so there was no dead giveaway. I have looked at that picture from the original post and there is what looks like a slight bulge by the shoulder, but a SAAMI spec full length resizing die will actually give you a much larger bulge than that.

Did the rounds chamber easy? No, when the bolt stopped short, I extracted and looked at the bullet, which was abraded slightly in a limited area of one side, and having not loaded these rounds before but having loaded many long 250’s, especially in .308 bore-rider barrels, my thought was that the bullet isn’t perfectly aligned from the seating process and the bore will align it if gently tapped. A few taps with a plastic screwdriver handle put the bolt handle in place against the receiver. Even more specifically, the resistance to movement from tapping did not increase, it decreased, and the bolt closed downward perfectly normally and easily. This is all what I would expect from slight misalignment, being corrected in the throat, which was not material for a 7 foot dirt shot, but in hindsight it was probably mainly neck resistance.

That’s why I took a picture of the necks, but they aren’t very remarkable to my eyes for frictional drag. They are probably too clean, and the higher pressure one is cleaner. I’ve gleaned this means insufficient clearance. The bottom line is the diameter difference is 20% less than a hundredth of an inch, that on a big cartridge and bullet, especially if a chamber was sloppy or the necks were turned, and a guy works up from a very low starting charge, could have been hard to discern.

When I saw Ray’s post, it jibed with these observations I had, behind the scenes. It’s important for me to flesh them out because guys could be thinking, wait, is there any difference in these smallest increments, yes, and shot two felt like shot one in every way, and the differences are big enough to mechanically and consistently reveal what’s going on.

On barrel support, absolutely. I think we said at the time this barrel finished at 35 pounds. Even on my F-Class barrels I use a semi compressible material in the channels to help support the barrels. My actions and tenons are likely strong enough, guys even run 700’s and aluminum bodied actions, but then how about the escutcheons and the threads of the screws and the actions when the barreled actions want to vibrate? I just prefer to use what is there anyway, the fore end, for additional support and harmonic dampening. I try to place some material where the front rest contact, the stock, and compressible material, and the barrel all coincide vertically.

Last edited:

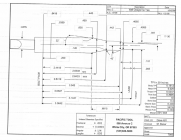

this is a 408 cheytac reamer print. the free/bore throat is 0.4085” diameter. you are trying to push a 0.416” cal bullet into there upon chambering, that is whats causing your resistance, not bullet misalignment.

I am shocked you even got the bolt to close

I am shocked you even got the bolt to close

Attachments

A key thing to note here. On the headstamp of your brass, it states 408. On your box of bullets, it states 416. While you proved it’s possible to fire a bullet of a larger caliber in a smaller barrel, I wouldn’t really recommend making a habit of it. Granted we’re only talking .008” different on a larger bullet, but still not a great idea

Must have a very liberal amount of neck clearance!This is pretty wild in the world of elr. What’s your loaded neck diameter? I’m surprised you ever got the bolt to close. Swaging the bullet down .008” is only part of the problem.

A key thing to note here. On the headstamp of your brass, it states 408. On your box of bullets, it states 416. While you proved it’s possible to fire a bullet of a larger caliber in a smaller barrel, I wouldn’t really recommend making a habit of it. Granted we’re only talking .008” different on a larger bullet, but still not a great idea

Agree. Understand though, it was not the intent to fire a larger bullet than specified.

This is bad in so many ways, but now I really want to see this pushed to pressure and see if the bullets stick together and if you have enough twist to stabilize them at their new length

My guess is that they would not survive. I think what we consider a “tight” bore option, is only one thou undersized. My tightest grouping barrels were of this variety, but they also were the barrels that when hot, liberated my bullet jackets.

There were though, coned barrels I’ve read of that would fire .22LR with an exit diameter of .177, both faster and more accurately than straight bores would.

@davidjoe what is the twist on the barrel

It’s a 1:10 twist, 6 groove Krieger. I did the rod spin test on it. This barrel sat as a blank for a long time and I couldn’t recall for certain.

Last edited:

Taper bores were used on anti-tank guns during the Second World War, with varying degrees of success. Sub-caliber penetrators with collapsible aluminum drive bands were driven to remarkable velocities out of these, but barrel fouling and wear were difficult problems to solve at the time. The advent of accurate and reliable sabot-encased ammunition, like the APFSDS round, pushed the taper-bore into obsolescence.My guess is that they would not survive. I think what we consider a “tight” bore option, is only one thou undersized. My tightest grouping barrels were of this variety, but they also were the barrels that when hot, liberated my bullet jackets.

There were though, coned barrels I’ve read of that would fire .22LR with an exit diameter of .177, both faster and more accurately than straight bores would.

Here's a good read on the topic: https://weaponsman.com/exotic-barrels-part-1-squeeze-bores/

it appears you have PLENTY of stability with the 500 grain a tipsIt’s a 1:10 twist, 6 groove Krieger. I did the rod spin test on it. This barrel sat as a blank for a long time and I couldn’t recall for certain.

Attachments

ImBIllT

Silver $$ Contributor

The biggest safety issue will be neck clearance. Measure a loaded round’s neck diameter, and your two fired cases’ neck diameters. If the fired cases aren’t at least .001” bigger than your loaded round, then you don’t have enough neck clearance in your chamber to shoot .416” bullets. Even if this brass is okay, a different brand might not be.

Obviously you could destroy jackets by sizing the bullet down too much in the barrel, but if that problem doesn’t show up, then it might not matter.

The flats on your calipers combined with the curvature of the bore, mean you probably didn’t get a good measurement on your barrel diameter, although you may or may not be quite close. A small hole gauge could give you an accurate diameter of the lands, but not the grooves.

You definitely have two considerations. What’s your chamber’s neck diameter? And what’s your barrel’s actual diameter? You can get pretty close to your neck diameter by measuring the fired case neck, and even though it won’t be the same as your chamber’s neck, you need a fired case to be at least .001” bigger than a loaded round, so that will tell you what you need to know.

Obviously you could destroy jackets by sizing the bullet down too much in the barrel, but if that problem doesn’t show up, then it might not matter.

The flats on your calipers combined with the curvature of the bore, mean you probably didn’t get a good measurement on your barrel diameter, although you may or may not be quite close. A small hole gauge could give you an accurate diameter of the lands, but not the grooves.

You definitely have two considerations. What’s your chamber’s neck diameter? And what’s your barrel’s actual diameter? You can get pretty close to your neck diameter by measuring the fired case neck, and even though it won’t be the same as your chamber’s neck, you need a fired case to be at least .001” bigger than a loaded round, so that will tell you what you need to know.

it appears you have PLENTY of stability with the 500 grain a tips

Yeah, many years back, probably about 7, I was perusing the Krieger inventory list online. I saw that barrel and thought, I have no real need for that, but I bet they had a cancellation, and how often will something like this be available. I knew this would sit idle with me, and thought, if I was supposed to be the buyer, then they’d accept $500 for it, and I called them. I know I was only drawn to it for the ability to stabilize anything out there. My smith of told me on this one he didn’t cut off the button for me to save, as is my habit. I smiled. It was a lot of cutting, I know, but if he wanted a 2 inch button for a keepsake I’m more than fine with that anyhow, but that’s why I couldn’t lay hands on the twist rate.

Last edited:

IM, ^

Looking at bullet selections that are the proper diameter for this barrel, it’s a little unfortunate that either, one of the separate calibers didn’t die off back in time, or that CheyTac selected this particular one. I’ll stick with this project by the book, though, as I also bought the reamer for any future barrels. For me, needing to tap the bolt closed is a no-go under any scenario, and I won’t neck turn brass. I did tap the bolt handle base for these two test rounds, thinking it was just an alignment issue.

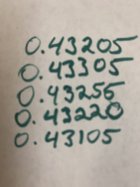

On my fired brass neck sizes, which do rechamber under a closed bolt with zero resistance, each piece measured as indicated below.

I measured five pieces of virgin brass as well.

How are these diameters, relative to expectations?

Looking at bullet selections that are the proper diameter for this barrel, it’s a little unfortunate that either, one of the separate calibers didn’t die off back in time, or that CheyTac selected this particular one. I’ll stick with this project by the book, though, as I also bought the reamer for any future barrels. For me, needing to tap the bolt closed is a no-go under any scenario, and I won’t neck turn brass. I did tap the bolt handle base for these two test rounds, thinking it was just an alignment issue.

On my fired brass neck sizes, which do rechamber under a closed bolt with zero resistance, each piece measured as indicated below.

I measured five pieces of virgin brass as well.

How are these diameters, relative to expectations?

Attachments

Last edited:

Similar threads

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.