gunsandgunsmithing

M.Ezell

I don't disagree at all but I don't really expect to see gains in accuracy, as my main goal is to smooth that transition area and do away with sharp edges that simply create a heat sink and allow erosion to begin, sooner, is my thinking. Hoping for somewhat better bbl life but I sure wouldn't complain if it makes for better accuracy too. I use the analogy of a fresh bandsaw cut...that burr left. Now wave a torch over it and that burr will glow almost instantly. But, polish that burr nice and smooth and no glow, not even warm in the same amount of time in the flame. That transition would be about 3x as long and less abrupt.This is an interesting read and proves that we are always looking for ways to make improvements and or progress.

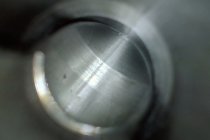

I like to visualize things so I took a picture of the area this thread is talking about. In the photo you can see the end of the brass, followed by a gap, and then the dark looking section is the 45 degree angle. This picture also shows a view looking head on and you can see the case is proud in relation to this area. So this section would be a turbulent area when the cartridge was fired.

View attachment 1397489

Probably a waste of time but I don't see much of a down side and I need a new reamer anyway. Lol!

No turn chambers is part of what got me thinking about this. A thinner neck/tight neck chamber will have a shorter step than a no turn, right? I like my no turn stuff and just trying to maximize their potential I guess.

Last edited: