Anyone trimming bullet meplats to make OAL the same?

If you're going to sort bullets by OAL to facilitate pointing or increase seating depth consistency, measure OAL

before trimming. Otherwise, the way many people set the trimmer using a shorter bullet then trimming all the rest to that length will throw everything off in terms of OAL.

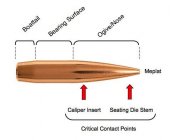

The process of length-sorting bullets by OAL for the purpose of improving seating depth (CBTO) consistency is based on the idea that bullets typically have much greater length variance in the nose region than they do in the boattail or bearing surface. Much of the OAL variance we normally observe within a Lot# of bullets is due to length variance in the nose region. That is not to say there isn't any length variance in the boattail or bearing surface segments, just that the length variance within the nose region is usually much greater. Further, the distance between two critical contact points that determine seating depth, meaning

1) the point where the seating die stem contacts and "pushes" the bullet down into the case, and

2) where the caliper insert seats on the ogive just above the top of the bearing surface when measuring CBTO, is

fixed (see attached image below). What that ultimately means is that sorting bullets by OAL is analogous to sorting by nose length, the whole idea being to sort bullets such that the distance between these two critical contact points is very close for all bullets within a single length group. Because the boattail and bearing surface segments fall outside the nose region, sorting bullets by BTO is not going to help with seating depth variance (i.e. CBTO variance) that is caused by bullet nose length variance.

For the OP - I sort bullets by OAL into groups of .0015"

total spread within a single length group. But the next group will start at .0005" longer, so there is really .002" between groups. For example, Group 1 might 1.5000" to 1.5015" in length, Group 2 would cover 1.5020" to 1.5035", Group 3 would cover 1.5040" to 1.5055", and so on. I started doing this for the purpose of pointing bullets, but soon appreciated that it also helped make seating depth more consistent without the need for twirling the seating die micrometer by as much as a few thousandths in either direction to ensure that every bullet seated with the same CBTO measurement.