You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

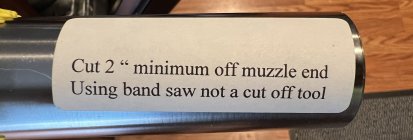

Broughton - use band saw, not cutoff tool?

- Thread starter LVLAaron

- Start date

I always use a band saw, But I doubt the barrel will turn to dust, You might need to clean it up by turning the face off a little more than usual, But I have parted barrels before and nothing happened, But I worked for a rifle builder and we used a bandsaw, So that's what I do now. Lucky score on the Brougton, My most accurate rifle has a Broughton on it, I wish I could find a Heavy Palma 7.5 twist 284.

LVLAaron

Gold $$ Contributor

Are they talking about a lathe parting tool or an abrasive cut-off wheel like on a grinder or cut-off saw.

Don't know! I can see why you wouldn't want to use an abrasive cutoff wheel. But it's not clear.

Dusty Stevens

Shiner

I cut em all with a portaband while in the lathe

LVLAaron

Gold $$ Contributor

IllegalI cut em all with a portaband while in the lathe

Doug Beach

Silver $$ Contributor

I part them off .120” (an arbitrary number I pulled out of somewhere) longer than finished length, then face and crown. The inch I typically part off is slightly too warm to hold comfortably, but that’s it. I don’t know why I’d want to bring another tool into the equation, when it has to go in the lathe anyway, and it might take 2 minutes (maybe) to do the part-off. I would need to see a really convincing argument that this is a bad idea.

My guess would be the pressure needed with a parting tool. And then not taking enough material off, for a nice clean crown. Just my .02.

Paul

Paul

That ^^^^^^, and there are lots of, shall I say, "not machinists" who are chambering barrels. A cut-off tool, a parting tool is not the best tool for a novice. Everything has to be right when you engage that cut-off to the work. Broughton has to cover their rear as they have no control over the methods, knowledge and experience of the person doing the work. If you can read a tape measure, the band saw is probably the best method to cut-off excess material without screwing up.My guess would be the pressure needed with a parting tool. And then not taking enough material off, for a nice clean crown. Just my .02.

Paul

Last edited:

DaveTooley

Gold $$ Contributor

One day I noticed a shadow of sorts on the face of the tenon shoulder. Compared to what we do on a manual machine I'm fairly aggressive when using the Haas. .040" deep cuts, .006" feed @ 325 SFM which is around 1000+ RPM's depending on diameter. I always leave 10-20 thou to clean up with a grooving tool. Just for hell of it one day I kept moving the shoulder forward. At + .040" I still had the shadow ring on the tenon face. If pulling a button through a barrel requires stress relieving then parting off the muzzle in a button rifled barrel could induce dimensional changes.

Walt Krafft

Gold $$ Contributor

If the muzzle area has a taper to it, it will be hard to chuck it tight enough to use a cutoff tool safely. I have seen and heard some pretty good wrecks when guys were using a cutoff tool when they probably shouldn't.

Didn't we see that weekly here, on this "gunsmithing" board, a few years ago? Some trying to work too far away from the jaws, blade sticking out way too far from the tool holder and not square to the work and on center or just a thou or 2 above, and then on a lathe that is really too light and lacks the rigidity to run a cut-off? Then add in the taper on the barrel, itself.If the muzzle area has a taper to it, it will be hard to chuck it tight enough to use a cutoff tool safely. I have seen and heard some pretty good wrecks when guys were using a cutoff tool when they probably shouldn't.

Last edited:

Parting off tools are great when used properly..set the height.no more blade protrusion than necessary.set speeds and feeds correctly.part as close to the jaws-collet as one can.use a revolving center if necessary for more rigidity.. keeping everything rigid is key.apply coolant-cutting oil.i use one regularly for different jobs.no problems..a hacksaw is another alternative.

I think Tim started using that sticker cause a lot of folks have no clue how to use a.

Parting tool and coolant.

Parting tool and coolant.

Similar threads

- Replies

- 11

- Views

- 4,328

- Replies

- 9

- Views

- 2,344

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.