You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

winchester model 52

- Thread starter rebs

- Start date

wkdickinson

Gold $$ Contributor

I have a M52B Target (what they called a "heavy" barrel), built in 1937. It has a barrel a band, it is setup for a Unertl style scope, with blocks on the front receiver ring and the the barrel. It shoots amazingly well! However, it is not a 100 yd. competitor. But being 65 years old, it sure can keep this 68 yo humble.

The b model was the last rifle to have a band. The c,d had screws in the fore end to apply pressure on barrel for tuning.

I know the band itself is engraved with a US Patent registration number. It’s very perplexing to me that makers of the most accurate rifles back then, sure seemed certain that free floating wasn’t the way to go.

Free-floating occurred to them as these solutions were clearly devised to counteract free floating. I don’t understand the change, myself, having become a new shooter in the transition era.

There were articles everywhere about how a rifle barrel was free floated. Of course, it’s not difficult to cut channels larger than a barrel, and I’ve never understood what prompted the change, or how “free floating” is even a technical feature to list. It would be like bragging that a manufacturer has made the effort to not checker a hunting rifle’s grip.

I can understand how wooden stocks absorb moisture and and twist from that, but when composites became the standard for accurate rifles about the same time contact was falling out of favor, and they don’t twist, shrink, or grow, the die had apparently already been cast against contact.

It was still in major manufacturing minds in the late 70s to have the stock have pressure on the barrel . Even varmit rifles 700 and 70 , even the 40 x rimfire had adjustable screws for pressure. Ive sanded out the pressure points on dozens if not hundreds of stocks while a smith . Amazing the difference in accuracy, mostly . If I remember correctly, the post 64 win 70 was disliked for the large gap around the barrel , common thinking of the time was ti inlet as close to the metal as possible. The sign of a good stock maker was his ability to be gapless . Boy times have changed .I know the band itself is engraved with a US Patent registration number. It’s very perplexing to me that makers of the most accurate rifles back then, sure seemed certain that free floating wasn’t the way to go.

Free-floating occurred to them as these solutions were clearly devised to counteract free floating. I don’t understand the change, myself, having become a new shooter in the transition era.

There were articles everywhere about how a rifle barrel was free floated. Of course, it’s not difficult to cut channels larger than a barrel, and I’ve never understood what prompted the change, or how “free floating” is even a technical feature to list. It would be like bragging that a manufacturer has made the effort to not checker a hunting rifle’s grip.

I can understand how wooden stocks absorb moisture and and twist from that, but when composites became the standard for accurate rifles about the same time contact was falling out of favor, and they don’t twist, shrink, or grow, the die had apparently already been cast against contact.

Joe Farmer, a legendary prone smallbore shooter, used an "electric bedding" system on all of his rifles. His last rifle was a Blieker that he stocked himself. All bedding systems and tuners have the same goal, manage the harmonics of the barrel. There is a lot of witchcraft involved.

Joe Farmer, a legendary prone smallbore shooter, used an "electric bedding" system on all of his rifles. His last rifle was a Blieker that he stocked himself. All bedding systems and tuners have the same goal, manage the harmonics of the barrel. There is a lot of witchcraft involved.

Hello Bennett, good to see/read you, I guess my question would be, surely they tested all this out back then, and found better results with a supported or dampened barrel, right? It’s not easy to barrel block a gun or sleeve a barreled action. It’s a little easier to install the type of band that Winchester patented, to deaden vibrations, or screw posts like both the 52 and 40X had. But the very easiest thing a manufacturer could possibly do, is just with one pass, bore a non-critical 1/8 to 3/16 oversize channel clearance around the entire barrel and call it done. It has to be cut anyway. Why would they go to such lengths for a less accurate result than not doing anything.

Heads were on guys pretty tight back then, after all, in that long period of time for decades, when barrels were supported and vibrations dampened - with the stock. Not to put my generation down, or anyone else’s, but show me just where we have gotten smarter since those days?

(It’s a refrain of mine, I know, as some may read, but it’s so perfectly logical to dampen barrels using the stock that I just can’t get away from it. It makes too much sense for gravity to pull the barrel onto a compressible dampening shim, that is exerting a bit of pressure upward, all of which occurs right over the head of the rest, such that if one extended a line through the top of the barrel, to the bottom of the rest’s screw, the only place where there would be dead air is inside the barrel bore and everything else is fully supported and in resonance-minimizing compression with each other).

Last edited:

The main issues with relying on the wood stock is the change with humidity / temperature and the force applied when the shooter is in position with a sling.

In the times of the 52’s development, extremely tight slings and shoulder pressure were common to the point shooters had to roll into their prone position. This would make the fore end shift. By limiting the contact by widening the barrel channel and using the two screws in the forearm, it could be effectively tuned to an acceptable level for that time period.

In the times of the 52’s development, extremely tight slings and shoulder pressure were common to the point shooters had to roll into their prone position. This would make the fore end shift. By limiting the contact by widening the barrel channel and using the two screws in the forearm, it could be effectively tuned to an acceptable level for that time period.

Lifesfordeath

Life is but a dream...

We tend to automatically assume free floating = best accuracy. This isn't the case all the time in my opinion. Adding a pressure pad to my kimber 82 Gave new life to the old gal but not quite the same as using a barrel band.

To answer the OPs question, it all depends. All my 52s except my D have a barrel band. My pre A, A (AL Freeland rifle), B and C all shoot very well. The D edges them with a better trigger and currently wears a tuner. Take the tuner off and they all are about equal IMO with the Freeland getting an edge. The pre A is probably the most consistent, she doesn't shoot overly large nor are true single hole groups the norm...just nice round groups from the old gal.

Your mileage will vary, obviously now no one's using a barrel band for accuracy but don't rule out using a pressure pad for it. I've seen it work, these rifles shoot very well especially against rifles of their time, 40x's, kimber 82s, 37s etc. Don't expect to win against full blown customs but it amazes me the groups guy were shooting with these rifles during those times with the ammo they had.

My 82G can usually outshoot any of my 52s or 40x with iron sights but they all are very close.

Attached are my 52s...notice the bands

To answer the OPs question, it all depends. All my 52s except my D have a barrel band. My pre A, A (AL Freeland rifle), B and C all shoot very well. The D edges them with a better trigger and currently wears a tuner. Take the tuner off and they all are about equal IMO with the Freeland getting an edge. The pre A is probably the most consistent, she doesn't shoot overly large nor are true single hole groups the norm...just nice round groups from the old gal.

Your mileage will vary, obviously now no one's using a barrel band for accuracy but don't rule out using a pressure pad for it. I've seen it work, these rifles shoot very well especially against rifles of their time, 40x's, kimber 82s, 37s etc. Don't expect to win against full blown customs but it amazes me the groups guy were shooting with these rifles during those times with the ammo they had.

My 82G can usually outshoot any of my 52s or 40x with iron sights but they all are very close.

Attached are my 52s...notice the bands

Attachments

Last edited:

Lifesfordeath

Life is but a dream...

To my knowledge, there are no barrel blocked guns in F-Class today, and except for my own, all of them are free floated.

This rifle’s 1.35” action, for example, was not intended to run a 32 inch straight taper 1.25”, with tenon almost identical to a 700. I think it’s not only more accurate to shim/support this barrel halfway down it, but it’s also easier on the receiver, the stock and the threading of both both the 5/32nds screw threads and action’s threads.

This rifle’s 1.35” action, for example, was not intended to run a 32 inch straight taper 1.25”, with tenon almost identical to a 700. I think it’s not only more accurate to shim/support this barrel halfway down it, but it’s also easier on the receiver, the stock and the threading of both both the 5/32nds screw threads and action’s threads.

Attachments

Last edited:

dellet

Gold $$ Contributor

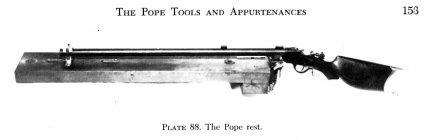

You might be interested in looking at the development of “Machine rests”. It’s possible that free floating barrels followed the refinement of the front rest as much as anything else.Hello Bennett, good to see/read you, I guess my question would be, surely they tested all this out back then, and found better results with a supported or dampened barrel, right? It’s not easy to barrel block a gun or sleeve a barreled action. It’s a little easier to install the type of band that Winchester patented, to deaden vibrations, or screw posts like both the 52 and 40X had. But the very easiest thing a manufacturer could possibly do, is just with one pass, bore a non-critical 1/8 to 3/16 oversize channel clearance around the entire barrel and call it done. It has to be cut anyway. Why would they go to such lengths for a less accurate result than not doing anything.

Heads were on guys pretty tight back then, after all, in that long period of time for decades, when barrels were supported and vibrations dampened - with the stock. Not to put my generation down, or anyone else’s, but show me just where we have gotten smarter since those days?. Realistically, they made 9x16” gunned battleships, followed by Concordes followed by affordable big blocks, while producing Saturn V’s with slide rules, pencils and acumen, in what 30 years. They didn’t have computers, they mastered mechanical things, and rifle basics are in that category. I don’t think we could make a single one of those things today. We are elated with getting a single 4-8-8-4 steam engine running again, not making a new one, just running what was an everyday sight in the 1950’s and 60’s. I have a hard time thinking they were wrong. We can’t beat a 1911, or a Mauser based bolt action, or even the profile of the solid lead, ancient .22 LR. We haven’t revolutionized cellulose powder, rifling, triggers or anything else. We still use for guns the enormous machines they made. But letting a rod of steel flap about, right at the finish line of accuracy efforts, they were just wrong on

? (Shaking a piece of rebar comes to my mind). We go to great pains to ensure one end of the barreled action is practically molecularly fused to the stock, - but the end that matters the most to accuracy just dangles in space like a diving board.

(It’s a refrain of mine, I know, as some may read, but it’s so perfectly logical to dampen barrels using the stock that I just can’t get away from it. It makes too much sense for gravity to pull the barrel onto a compressible dampening shim, that is exerting a bit of pressure upward, all of which occurs right over the head of the rest, such that if one extended a line through the top of the barrel, to the bottom of the rest’s screw, the only place where there would be dead air is inside the barrel bore and everything else is fully supported and in resonance-minimizing compression with each other).

An early example.

The front sled would be attached to a dead spot in the barrel, found by ringing. Tapping on the barrel with a hard object to find where there is no vibration or ring.

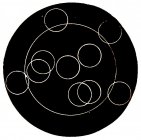

The story about this target is that the customer wanted to watch and wait for the barrel to be rifled and shot. 200 yards, 38 caliber.

Liven The Dream

Gold $$ Contributor

I had a HB B with No Band or screws in the Fore Arm.Are you saying that all 52 Bs had a bbl band?

I had C with HB and MB No Bands No Screws.

One of My C's was a Government Model had those Chickens Stamped in the Stock

Lifesfordeath

Life is but a dream...

To my knowledge, there are no barrel blocked guns in F-Class today, and except for my own, all of them are free floated.

This rifle’s 1.35” action, for example, was not intended to run a 32 inch straight taper 1.25”, with tenon almost identical to a 700. I think it’s not only more accurate to shim/support this barrel halfway down it, but it’s also easier on the receiver, the stock and the threading of both both the 5/32nds action and screw threads.

This! Forgot, my 37 has a pressure pad as well with a very heavy barrel and I agree you need that sometimes to support the heavy barrels and yes much easier on the actions and bedding!

Attachments

That gun shot very tight on the unlimited / open class target, doesn’t it seem unfair that these antique guns have to use it? The stock reminds me of a gun I bought some time back with a glued in 40-x .22 LR that I like very much as I found it.This! Forgot, my 37 has a pressure pad as well with a very heavy barrel and I agree you need that sometimes to support the heavy barrels and yes much easier on the actions and bedding!

I have a banded 52 set up for Sling and D model that I transferred to this stock I saw on the classifieds here. It’s though to find the action screws for a 52 now. I’ll be passing down my vintage .22’s; they are are too good to part with before then.

Attachments

Last edited:

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.