I recently inherited a Unertl 24x target scope with POSA mounts. There are a few ready made options for this scope with a drilled and tapped barrel like Rem 40x, varmint special, rimfire, etc. However, I have a savage PTA in 6BR that i would like to mount it on. There are people that make adapters for POSA to picatinny and other adapters like Steve Earle, but none appear to be exactly what I need. The main problem with the target scopes is the mounting distance should be 7.2" or more optimally, and this is difficult to achieve without a mount over or on the barrel.

So, my options for a home for this scope are buy a new rifle, have my rifle drilled (don't want to do that), or a custom mount. I plan to do a custom mount so I can have a unique setup on a rifle I already have.

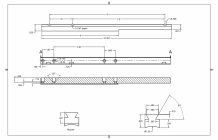

First step was to design the mount, I based it off of a regular savage round back scope rail. Tried to keep it simple to be easier to machine/print. My current design has a full 60 degree dovetail and mounting slots for 2 different 7.2" spacing spots or 1 9" spacing. May end up making it less tall overall. I could always add more mounting slots in the future if desired.

The initial plan was to buy a mill and machine it myself, but that would be more money than getting it machined or printed. Now the plan will be to have someone do it for me. There are several online based companies that will machine or 3d print your design in metal now, so I got some quotes.

Macined from aluminum

USA based - ~$400

Foreign - ~ $200

3D printed from Aluminum

~ $1000

Looks like the foreign based machining will be the most economical option. If anyone has gone through this process before, I am open to any tips.

So, my options for a home for this scope are buy a new rifle, have my rifle drilled (don't want to do that), or a custom mount. I plan to do a custom mount so I can have a unique setup on a rifle I already have.

First step was to design the mount, I based it off of a regular savage round back scope rail. Tried to keep it simple to be easier to machine/print. My current design has a full 60 degree dovetail and mounting slots for 2 different 7.2" spacing spots or 1 9" spacing. May end up making it less tall overall. I could always add more mounting slots in the future if desired.

The initial plan was to buy a mill and machine it myself, but that would be more money than getting it machined or printed. Now the plan will be to have someone do it for me. There are several online based companies that will machine or 3d print your design in metal now, so I got some quotes.

Macined from aluminum

USA based - ~$400

Foreign - ~ $200

3D printed from Aluminum

~ $1000

Looks like the foreign based machining will be the most economical option. If anyone has gone through this process before, I am open to any tips.