Good day all. I have a rather simple question regarding 9mm reloads as I am just getting started. I have run a small batch of 9mm reloads using a Lee single stage press and carbide dies using factory recommended die setups and loading 124 grain Berrys copper plated bullets with Titegroup at lowest powder charge. When I expand the brass I use just enough of a bell to accept the bullet into the case (not loose, clears the rounded edge on the base of the bullet). OAL is 1.16 per Berrys spec. So...when I apply a moderate crimp (i.e., about 2/3 of a turn on the adjustment knob after die contact with the round) there is still a visible bell in the case. It passes the barrel plunk test and the rounds feed well...no problem with cycling etc. Rounds are sooty about half way down the spent case....more soot than I am used to with factory rounds. Have not fired from a bench so accuracy still to be determined (shooter talent is variable here). So my questions are these: should that bell or flare in the case be removed in the reload process, or is some visible bell OK? And is the soot a possible result of lighter load vs belling in the case? Thanks for any feedback.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bell removal in 9mm reloads

- Thread starter JRSRPH

- Start date

NETim

Curmudgeon-at-large

If your pistol is functioning with the crimp as is, you're probably good to go. Generally, the crimp is set just enough to remove the bell on the case mouth. However, you may experience some difficulties in another 9mm pistol that has a tighter chamber. Who knows? Too much crimp isn't good either as it could potentially deform the bullet.

The sooty cases are probably due to the light loads. The case isn't expanding quite enough to seal off the case.

The sooty cases are probably due to the light loads. The case isn't expanding quite enough to seal off the case.

I load tons of Berry for years now.... You simply need to remove the belling not crimp.... Easy way to do that is to seat some bullets in empty brass , no powder , no primers.... Go ahead and crimp one , then tighten or loosen your crimp die , then crimp another.... Normally about 4 is enough... Pull those four bullets and inspect the crimp , a very light ring around the bullet is what your looking for if it's actually squeezing the bullet and indenting it that's to much..... Just a nice very light ring around the bullet is great....

With that said Berry bullets can take a hell of a crimp and not break the coating.... You go to much and it will effect accuracy.... I used to actually roll crimp into them on .38spl bullets and got pretty deep to see how much was to much but the bullets held up and shot even at WAY to much crimp...

I do suggest you use lead data because like lead Berry bullets are .356 instead of .355 like lead and build pressure like lead... I still use the old seating depth of 1.150 which was what was originally recommended but because people were using mid range FMJ data they were building pressure that wasn't needed , and you weren't gaining anything but pressure... I am not reloading your ammo you are so take ANYTHING you read on the internet that's not published data with a grain of salt...

THAT being said tight group is not a great powder for new reloaders because you can get a double charge without filling the case.... Be careful.... Your seeing sooty cases because your charge is as you said the lowest charge and it's not sealing the brass to the chamber.... I would bump it up if you want that to stop.. most cheap factory you buy does this.... I bumped up another tenth of a grain to stop it years ago... Reloading is safe IF you follow the safety rules , START LOW AND WORK UP being a great one to remember.... I , but this is me not you , normally start about the middle of the data and test from there.... If you don't have a crono yet , get one... Learn to look for pressure signs.... I never load a screaming hot bullet because they are normally not accurate and for pistol why..??? You shooting what 25 yards and the paper doesn't know the difference.... Make it easy on you and the gun.... If you find what your looking for a few tenths below max charge which I normally do it leaves you a little room for faster or even a slight charge mistake of a tenth or so...

With that said Berry bullets can take a hell of a crimp and not break the coating.... You go to much and it will effect accuracy.... I used to actually roll crimp into them on .38spl bullets and got pretty deep to see how much was to much but the bullets held up and shot even at WAY to much crimp...

I do suggest you use lead data because like lead Berry bullets are .356 instead of .355 like lead and build pressure like lead... I still use the old seating depth of 1.150 which was what was originally recommended but because people were using mid range FMJ data they were building pressure that wasn't needed , and you weren't gaining anything but pressure... I am not reloading your ammo you are so take ANYTHING you read on the internet that's not published data with a grain of salt...

THAT being said tight group is not a great powder for new reloaders because you can get a double charge without filling the case.... Be careful.... Your seeing sooty cases because your charge is as you said the lowest charge and it's not sealing the brass to the chamber.... I would bump it up if you want that to stop.. most cheap factory you buy does this.... I bumped up another tenth of a grain to stop it years ago... Reloading is safe IF you follow the safety rules , START LOW AND WORK UP being a great one to remember.... I , but this is me not you , normally start about the middle of the data and test from there.... If you don't have a crono yet , get one... Learn to look for pressure signs.... I never load a screaming hot bullet because they are normally not accurate and for pistol why..??? You shooting what 25 yards and the paper doesn't know the difference.... Make it easy on you and the gun.... If you find what your looking for a few tenths below max charge which I normally do it leaves you a little room for faster or even a slight charge mistake of a tenth or so...

divingin

Gold $$ Contributor

So my questions are these: should that bell or flare in the case be removed in the reload process, or is some visible bell OK? And is the soot a possible result of lighter load vs belling in the case? Thanks for any feedback.

Should be removed. Caveat: If it works, who cares? But yeah, it should be removed. Pull your seating stem up a bit, and give your die body a little "down". Run a loaded case in, pull it out and inspect. repeat until you get the case mouth where you want it. Then run the case back in and screw your seating stem in hard against the bullet, and lock everything in place. Remember that 9mm is supposed to headspace on the case mouth, so you don't need to roll the case mouth way into the bullet. Generally all you need is straight to a very slight inward roll (assuming roll crimp.)

Soot on the case is from lower powered loads not expanding the brass. Doesn't really hurt anything.

Xerothermic

Silver $$ Contributor

Doesn't the 9mm headspace on the cartridge mouth?I've found that even when using a taper crimp as on the 9mm/ .38 Super/ .45 etc., that there might be a slight edge on the case mouth after crimping. There's no need to over-crimp imo.

Buy a cartridge checker and if your reloads drop in and out freely you should be okay.

RegionRat

Gold $$ Contributor

Yes, it does headspace on the case mouth, contrast that against other cartridges being mentioned that headspace on the rim and are intended to have an actual roll crimp into a cannelure feature on the bullet like in the example of a .38Spcl/.357 Mag or typical revolver cartridge.Doesn't the 9mm headspace on the cartridge mouth?

FPNI

The 9mm Luger design is not intended to be crimped as in a roll crimp, but the word crimp causes confusion when the name appears in the nomenclature of the different dies and tooling. The above advice is good when it steers the OP into completely removing the flare, but it isn't intended to get an actual roll crimp since it is intended to headspace on the case mouth as mentioned.

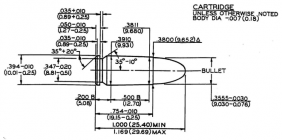

9mm Luger also features some slight body taper where the diameter of the mouth over the loaded bullet is 0.380" while down near the rim we are in the neighborhood of 0.391 - 0.394 ... and supposed to be as follows:

The "plunk test" was good advice, and even then you still need to live fire test for reliability.

I know I risk attracting flak for the next statements, but in this day and age it isn't wise to skip the chronograph. Even if the OP doesn't buy one, it is advisable to work up your load where you can borrow one to play it safe. The times when they were more rare or difficult to come by were one thing, but these days it is much safer for the inexperienced to run with a chrono than to learn pistol load development the hard way. Good Luck and play it safe. YMMV

ETA: see the photos in post #5 in this thread.

https://forum.accurateshooter.com/threads/9mm-pistol-oal-inconsistent.4003624/

Last edited:

Change powders. Titegroup powder is dirty as hell.

Thanks very much for the info.... really helpful!I load tons of Berry for years now.... You simply need to remove the belling not crimp.... Easy way to do that is to seat some bullets in empty brass , no powder , no primers.... Go ahead and crimp one , then tighten or loosen your crimp die , then crimp another.... Normally about 4 is enough... Pull those four bullets and inspect the crimp , a very light ring around the bullet is what your looking for if it's actually squeezing the bullet and indenting it that's to much..... Just a nice very light ring around the bullet is great....

With that said Berry bullets can take a hell of a crimp and not break the coating.... You go to much and it will effect accuracy.... I used to actually roll crimp into them on .38spl bullets and got pretty deep to see how much was to much but the bullets held up and shot even at WAY to much crimp...

I do suggest you use lead data because like lead Berry bullets are .356 instead of .355 like lead and build pressure like lead... I still use the old seating depth of 1.150 which was what was originally recommended but because people were using mid range FMJ data they were building pressure that wasn't needed , and you weren't gaining anything but pressure... I am not reloading your ammo you are so take ANYTHING you read on the internet that's not published data with a grain of salt...

THAT being said tight group is not a great powder for new reloaders because you can get a double charge without filling the case.... Be careful.... Your seeing sooty cases because your charge is as you said the lowest charge and it's not sealing the brass to the chamber.... I would bump it up if you want that to stop.. most cheap factory you buy does this.... I bumped up another tenth of a grain to stop it years ago... Reloading is safe IF you follow the safety rules , START LOW AND WORK UP being a great one to remember.... I , but this is me not you , normally start about the middle of the data and test from there.... If you don't have a crono yet , get one... Learn to look for pressure signs.... I never load a screaming hot bullet because they are normally not accurate and for pistol why..??? You shooting what 25 yards and the paper doesn't know the difference.... Make it easy on you and the gun.... If you find what your looking for a few tenths below max charge which I normally do it leaves you a little room for faster or even a slight charge mistake of a tenth or so...

This is what I have been told by the avid loaders... will use it up and move on. Luckily I like to clean guns...while listening to Bob Seger. Thanks again.Change powders. Titegroup powder is dirty as hell.

I will give this a try.....sounds just challenging enough for a newbie without being too dangerous if I make a withdrawal from my common sense account.Should be removed. Caveat: If it works, who cares? But yeah, it should be removed. Pull your seating stem up a bit, and give your die body a little "down". Run a loaded case in, pull it out and inspect. repeat until you get the case mouth where you want it. Then run the case back in and screw your seating stem in hard against the bullet, and lock everything in place. Remember that 9mm is supposed to headspace on the case mouth, so you don't need to roll the case mouth way into the bullet. Generally all you need is straight to a very slight inward roll (assuming roll crimp.)

Soot on the case is from lower powered loads not expanding the brass. Doesn't really hurt anything.

Good point...I will try a plunk test in my sig sauer and h and k...good to go in glock. Will also go up a smidge in load but nothing radical....change on thing at a time..thanks much.If your pistol is functioning with the crimp as is, you're probably good to go. Generally, the crimp is set just enough to remove the bell on the case mouth. However, you may experience some difficulties in another 9mm pistol that has a tighter chamber. Who knows? Too much crimp isn't good either as it could potentially deform the bullet.

The sooty cases are probably due to the light loads. The case isn't expanding quite enough to seal off the case.

Seems to be the consensus re: pressure in the case.....thanks for the input. Appreciated.Soot from low pressure. Case not fully sealing in the chamber. adjust the die enough to remove the flare completely

Cartridge gauge now ordered....good call...again appreciated.I've found that even when using a taper crimp as on the 9mm/ .38 Super/ .45 etc., that there might be a slight edge on the case mouth after crimping. There's no need to over-crimp imo.

Buy a cartridge checker and if your reloads drop in and out freely you should be okay.

Really appreciate the insight and graphics....good stuff for new reloaders!Yes, it does headspace on the case mouth, contrast that against other cartridges being mentioned that headspace on the rim and are intended to have an actual roll crimp into a cannelure feature on the bullet like in the example of a .38Spcl/.357 Mag or typical revolver cartridge.

FPNI

The 9mm Luger design is not intended to be crimped as in a roll crimp, but the word crimp causes confusion when the name appears in the nomenclature of the different dies and tooling. The above advice is good when it steers the OP into completely removing the flare, but it isn't intended to get an actual roll crimp since it is intended to headspace on the case mouth as mentioned.

9mm Luger also features some slight body taper where the diameter of the mouth over the loaded bullet is 0.380" while down near the rim we are in the neighborhood of 0.391 - 0.394 ... and supposed to be as follows:

View attachment 1338272

The "plunk test" was good advice, and even then you still need to live fire test for reliability.

I know I risk attracting flak for the next statements, but in this day and age it isn't wise to skip the chronograph. Even if the OP doesn't buy one, it is advisable to work up your load where you can borrow one to play it safe. The times when they were more rare or difficult to come by were one thing, but these days it is much safer for the inexperienced to run with a chrono than to learn pistol load development the hard way. Good Luck and play it safe. YMMV

ETA: see the photos in post #5 in this thread.

https://forum.accurateshooter.com/threads/9mm-pistol-oal-inconsistent.4003624/

100 %Soot from low pressure. Case not fully sealing in the chamber. adjust the die enough to remove the flare completely

Coyotefurharvester

Silver $$ Contributor

Flare the mouth just enough so you get a pop when you pull the bullet out(by hand) after starting in the case by hand. Minimum flare less crimping needed. You can crimp(more) until you see some plating debris on the target at close range.

Deleted member fkimble@charter.net

You have 3 case guages, the barrels in your guns. A little trial and error testing will quickly show you which one has the tightest chamber. This is the one to use to check your ammo against. Different brands of chamber checkers have different size "chambers. You have two things to check, over all length with bullet seated and case fit. OAL must fit in the mags and chamber in the guns without hitting the rifleing. Case fitment, resized case must freely go in chamber. Bell needs to be removed just to the point where the case appears to have never been belled. And if/when you change bullets double check that they chamber freely. Different brands can look identical but their nose profile can be different enough to cause problems.

Sooting, yes too light of load and a dirty powder. A really bad combo.

Frank

Sooting, yes too light of load and a dirty powder. A really bad combo.

Frank

Similar threads

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.